What Makes a Reliable Product CNC Machining Supplier?

When sourcing a product CNC machining supplier, manufacturers prioritize precision, efficiency, and material expertise. EMAR stands out as a trusted partner with ISO-certified facilities capable of handling complex geometries across metals, plastics, and composites. Our 5-axis machining centers deliver ±.005mm tolerances for mission-critical components.

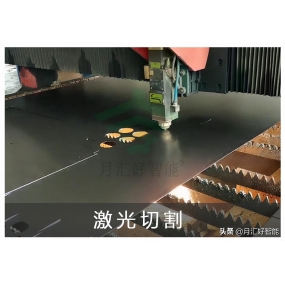

Comprehensive CNC Machining Capabilities

Our CNC machining services cover milling, turning, and Swiss machining for prototypes to high-volume production. We specialize in:

Aerospace-grade aluminum and titanium components

Medical device machining with biocompatible materials

Automotive parts with strict dimensional requirements

Custom fixtures and industrial equipment

Quality Assurance Process

Every product undergoes rigorous inspection using CMMs, optical comparators, and surface roughness testers. Our CNC machining quality control protocol includes:

First-article inspection reports (FAIR)

Statistical process control (SPC) monitoring

Material traceability documentation

Final dimensional verification

Why Choose EMAR as Your CNC Partner?

With 15+ years of machining experience, we offer:

DFM (Design for Manufacturing) consultations

Fast-turn prototyping (72-hour service available)

Competitive pricing with MOQ flexibility

IP protection through NDAs and secure data handling

Visit our website to request a free project evaluation and discover how our CNC solutions can optimize your supply chain.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque