In the realm of precision manufacturing, non-standard CNC stainless steel parts play a pivotal role across industries such as aerospace, medical devices, and automotive. EMAR, a trusted name in CNC Machining, specializes in delivering high-quality, custom-engineered solutions tailored to your unique specifications.

Understanding Non-Standard CNC Stainless Steel Parts

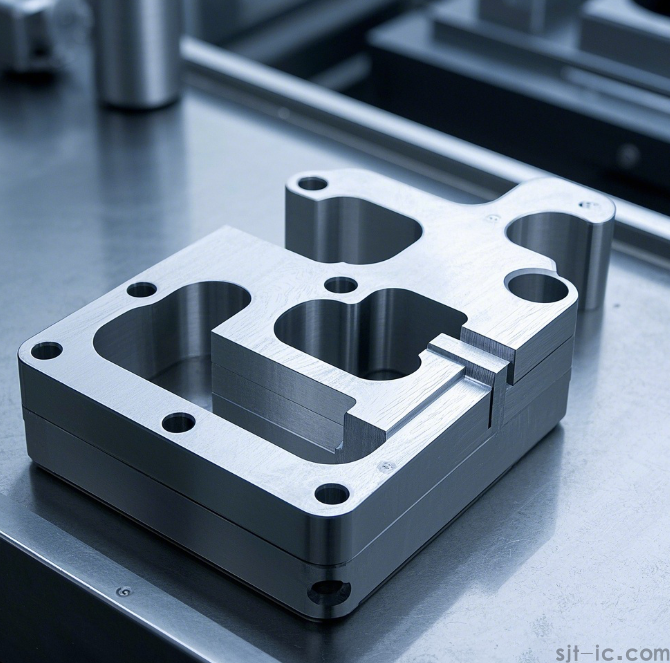

Unlike standard off-the-shelf components, non-standard parts require meticulous design adaptation and advanced machining techniques. Stainless steel (grades 303, 304, 316, etc.) is favored for its corrosion resistance, durability, and machinability, making it ideal for complex geometries and tight-tolerance applications.

Key Advantages of EMAR’s Manufacturing Process

1. Precision Engineering: Our 5-axis CNC machines achieve tolerances as tight as ±.005mm.

2. Material Expertise: Optimized toolpaths for stainless steel to minimize burrs and thermal deformation.

3. End-to-End Solutions: From CAD/CAM prototyping to surface treatment (e.g., passivation, polishing).

Industry Applications

EMAR’s CNC stainless steel parts serve critical functions in:

- Medical: Surgical instruments, implantable components.

- Energy: Valve systems, pump housings.

- Automotive: Fuel injection parts, sensor mounts.

Why Choose EMAR?

With ISO 9001-certified facilities and a 100% quality inspection protocol, we ensure every component meets aerospace-grade standards. Our engineers collaborate closely with clients to overcome challenges like thin-wall machining or thread integrity.

Explore EMAR’s capabilities at www.sjt-ic.com and request a free DFM analysis today.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque