Finding a CNC Machining supplier is easy. Finding a reliable, high-quality one? That's the real challenge. 😓 You might be a procurement manager comparing ten quotes, or an engineer frustrated with inconsistent parts. The lowest price is tempting, but a single batch of faulty components can cost you more in delays and rework than you ever saved. So, how do you look beyond the price tag and truly assess quality? Let's break it down together.

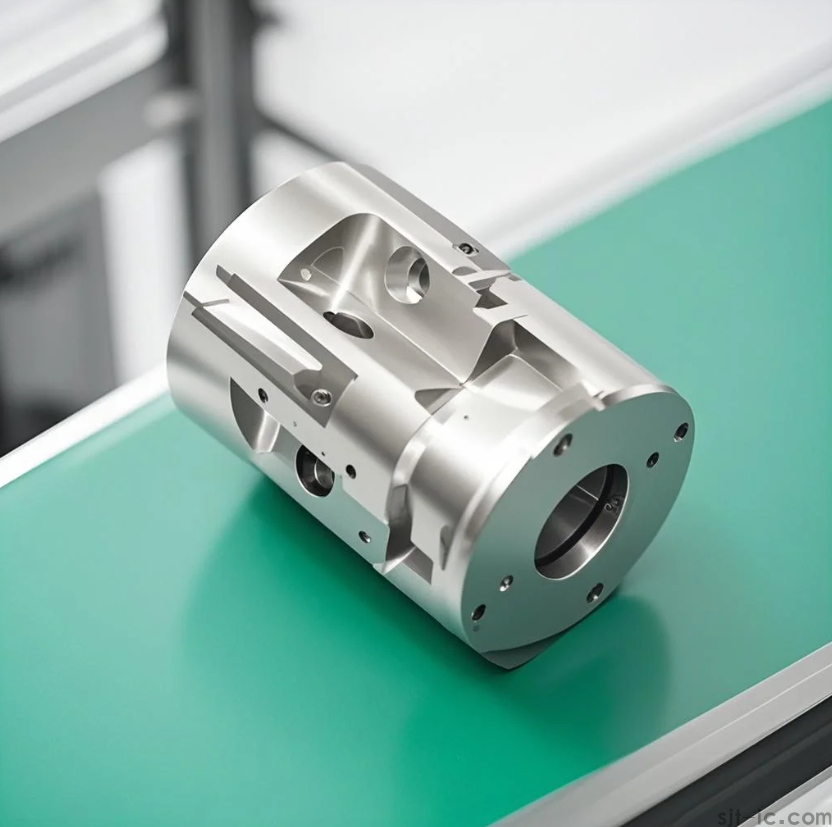

Start With Their Tools and Tech Talk

First things first, what's in their workshop? A supplier's equipment list is like their resume. Don't just look for “CNC machines”—ask about the brands, ages, and maintenance schedules. Newer, well-maintained machines from reputable brands (think DMG Mori, Haas, Mazak) generally offer better precision and consistency.

But here's the thing: The fanciest machine is useless without a skilled operator. 🛠️ When you talk to them, listen. Can they explain why they'd choose a 5-axis machine over a 3-axis for your part? Do they discuss tooling strategies or fixturing methods to ensure accuracy? This technical dialogue is your first real clue about their depth of knowledge.

Peek Into Their Process: It's All in the Details

Quality isn't an accident; it's baked into the process. You need to ask about their quality control (QC) workflow. A trustworthy supplier will have clear, documented steps.

- In-process Inspection: Do they check parts during machining, not just at the end? This catches errors early.

- Final Inspection Tools: What do they use? Basic calipers, or advanced gear like CMMs (Coordinate Measuring Machines) or optical scanners for complex geometries?

- Documentation: Will they provide inspection reports with actual measurements? This is gold for your records.

A vague answer like “we check everything” is a red flag. You want specifics. This might indicate a lack of a structured system, which is a risk.

The Communication Test: Are They Problem-Solvers?

Here’s a personal take: a supplier's communication style before you place an order often predicts their performance after. You're not just buying parts; you're buying a partnership.

When you send an RFQ, do they:

✅ Ask clarifying questions about your design or application?

✅ Flag potential manufacturability issues and suggest DFM (Design for Manufacturability) improvements?

✅ Provide a clear, detailed quote that breaks down costs?

If they just shoot back a price with no questions, be cautious. They might be cutting corners on understanding, which leads to mistakes. A proactive, questioning partner is usually a quality-conscious one. 🤝

The Ultimate Proof: Request a Sample Run

Words and promises are one thing. Physical parts are another. If your order volume justifies it, always start with a prototype or small batch. This is the most reliable test.

Evaluate the sample for:

👉 Surface Finish: Is it smooth and consistent, free of unexpected tool marks?

👉 Dimensional Accuracy: Measure it yourself. Does it match your drawing tolerances?

👉 Material & Certification: Is it the correct material grade? Can they provide material certification if needed?

This sample run tests everything at once: their machines, their process, and their attention to your specs.

Don't Forget the Paperwork (The Boring But Crucial Stuff)

Finally, ask about certifications and policies. While not a guarantee of daily quality, they show a commitment to standards.

- ISO 9001: This certification means they have a documented quality management system. It's a good baseline.

- Industry-Specific Certs: For automotive, aerospace, or medical parts, this is critical.

- Non-Conformance Policy: What happens if a batch fails inspection? A professional supplier will have a clear return and rework policy.

In my experience, a supplier that is organized with their paperwork tends to be organized on the shop floor. It’s all connected.

Evaluating a CNC supplier takes a bit more work upfront, but it saves massive headaches later. Think of it as an investment in peace of mind and project success. We hope this guide helps you build a sharper eye!

Ready to put these questions to the test with a supplier who values transparency? Our team is built to meet these exact criteria. Why not share your drawings with us and see how we respond? 💬 Click to connect with our engineering team today for a detailed, no-obligation consultation.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque