Stuck in the endless loop of Google searches and supplier directories, trying to find a reliable partner for your small-batch CNC project? 😩 You're not alone. For engineers, procurement managers, and startup founders, finding the right machine shop for custom, low-volume parts often feels like searching for a needle in a haystack. The big names want huge orders, and the shady ones promise the moon but deliver scrap. So, what's the real playbook? Let's cut through the noise and talk about how to actually find a manufacturer you can trust, not just click on.

Where should you even start looking?

Most folks jump straight to B2B platforms or a frantic “CNC Machining near me” search. That's okay for a list, but it's a messy starting point. I often start by tapping into my professional network first – a quick ask in relevant engineering forums or LinkedIn groups can yield gold, with real user experiences. Online directories are useful, but treat them as a phonebook, not a review site. The key here is to look for shops that explicitly mention “prototyping” or “low-volume” on their website. If their homepage only screams “mass production,” they might not be tuned for your needs. It’s a subtle signal, but an important one.

What separates a good small-batch shop from the rest?

This is where the rubber meets the road. A shop good at small batches gets your world. They should have:

• Quick and technical communication: They ask smart questions about your design intent, not just the drawing.

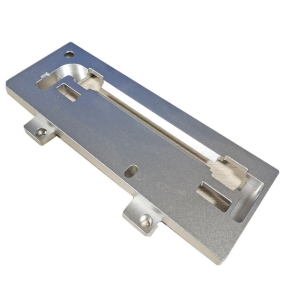

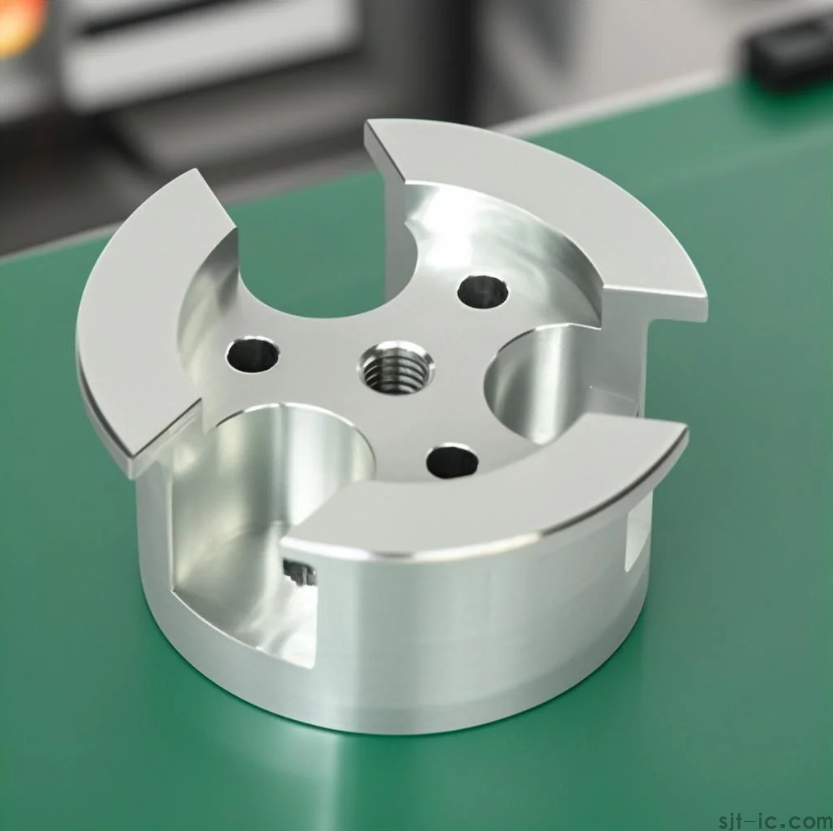

• Transparent about capabilities: Clear info on their CNC machines, max/min part sizes, and material stock.

• Process for prototypes: A defined workflow for first-article inspection and feedback loops.

Beware of shops that give you a price instantly without any queries. That might indicate a “quote-bot” or a lack of engineering scrutiny, which can lead to bigger problems later. A thoughtful delay for a proper review is a good sign, in my experience.

How do you vet them without visiting the factory?

You can't fly to every potential supplier, right? So, you get creative. First, a detailed RFQ (Request for Quote) is your vetting tool. Include not just the 3D file, but also critical questions: What is your first-article inspection process? How do you handle design for manufacturability (DFM) feedback? Can you provide material certifications?

Their response quality tells you everything. Next, insist on seeing real examples of similar work – photos, videos, even asking if they can send a sample part (you might pay for it). A video walkthrough of their facility is a common and reasonable request nowadays. Finally, check for any case studies or testimonials that mention collaboration on development phases, not just bulk order fulfillment.

Is the cheapest quote always the winner? Spoiler: No.

Let's be real, cost matters. But for small batches, the equation is different. A rock-bottom price might mean corner-cutting on setup, using worn tools, or skipping proper QA. The real cost isn't just the unit price; it's the cost of failed parts, project delays, and communication headaches.

I’ve seen projects where saving 15% on machining led to a 100% cost overrun in delayed assembly. When comparing quotes, look at the breakdown. Does it include DFM analysis? How about inspection reports? What’s their policy on revisions? Sometimes, a slightly higher price from a more communicative and proactive shop saves money and sanity in the long run. This perhaps suggests that the cheapest path isn't always the most economical one.

What about the “trial order” strategy?

This is the ultimate test. Starting with the smallest, least critical component in your batch is a brilliant move. It’s a low-risk investment to assess their actual performance: packaging, on-time delivery, part quality, and documentation (like inspection sheets).

Treat this first order as a paid audit. Measure everything. Are the parts within tolerance? Is the surface finish as specified? How was the communication during production? This hands-on data is worth more than any sales pitch. However, it's worth mentioning that even a perfect trial order for a simple part doesn't guarantee success with a complex one later. It greatly increases your confidence, but stay engaged.

Finding the right manufacturing partner is more detective work than shopping. It requires peeling back the marketing layers to see the operational reality. The goal isn't just to get parts made; it's to build a reliable extension of your team. By focusing on communication, process transparency, and strategic vetting, you move from guessing to knowing.

Ready to put this into practice with your next project? If you have specific drawings or questions about vetting a potential supplier, our engineering team is here to provide a second opinion. 👉 Get in touch with our online consultants to discuss your project specifics.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque