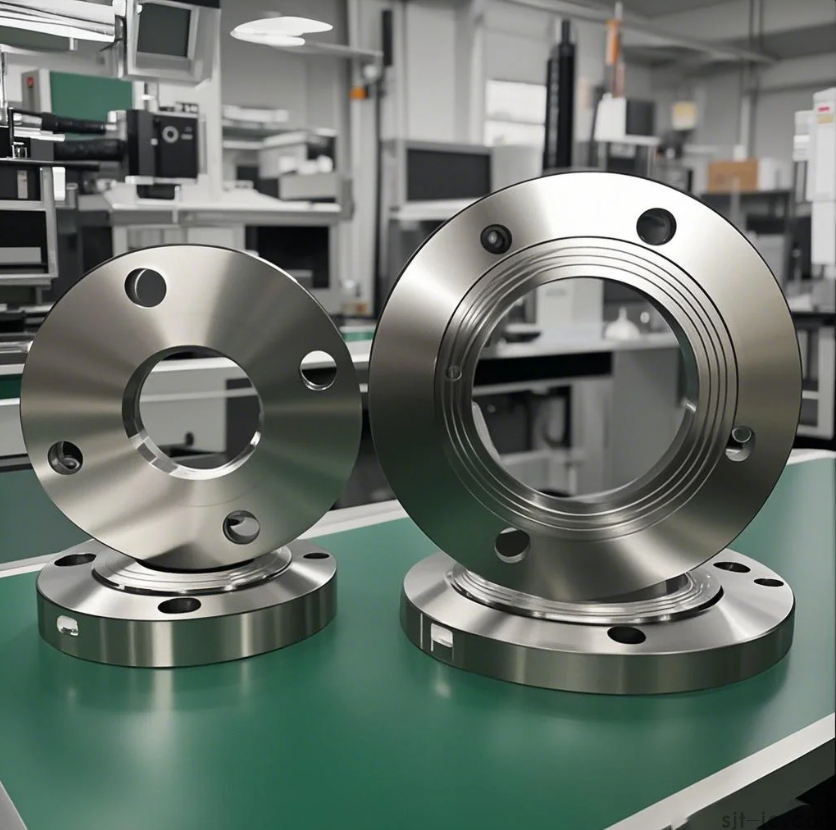

As a professional CNC stainless steel machining service provider, EMAR Company specializes in delivering high-precision components for industries ranging from aerospace to medical devices. This article will break down the critical steps of the process, address common challenges, and highlight how our expertise ensures superior results.

Understanding CNC Stainless Steel Machining

CNC stainless steel machining involves using computer-controlled tools to shape stainless steel into precise parts. Known for its corrosion resistance and durability, stainless steel (e.g., 304, 316 grades) requires specialized techniques due to its hardness and tendency to work-harden during cutting.

Key Steps in the Process

Material Selection: Choose the appropriate stainless steel grade based on application requirements (e.g., marine environments often require 316L).

Toolpath Programming: CAD/CAM software generates optimized toolpaths to minimize tool wear and ensure accuracy.

Machining Operations: Multi-axis CNC mills/lathes perform turning, milling, drilling, and threading with coolant systems to manage heat.

Quality Inspection: CMM and surface roughness testers verify dimensional tolerances (typically ±.005 inches or tighter).

Overcoming Machining Challenges

Stainless steel's properties demand specific strategies:

Use carbide or ceramic cutting tools with sharp edges to reduce work hardening.

Maintain consistent feed rates to prevent tool deflection.

Employ high-pressure coolant to extend tool life and improve surface finish.

Why Choose EMAR for Your Project?

Our CNC stainless steel machining capabilities stand out through:

15+ years of experience with complex geometries and tight tolerances.

ISO 9001-certified quality control systems.

Fast prototyping and bulk production with lead times 30% shorter than industry averages.

For projects requiring precision and reliability, contact EMAR to discuss your stainless steel machining needs.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque