In the realm of industrial fluid control systems, CNC stainless steel valve machining plays a pivotal role in ensuring reliability, durability, and leak-free performance. As a leading CNC Machining manufacturer, EMAR specializes in delivering high-precision valve components tailored to meet stringent industry standards.

Why Choose CNC Machining for Stainless Steel Valves?

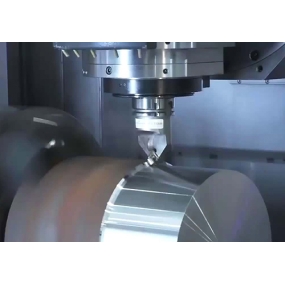

Stainless steel valves demand exceptional corrosion resistance and dimensional accuracy. Our 5-axis CNC machining centers enable complex geometries with tolerances as tight as ±.01mm, while advanced toolpath programming ensures optimal surface finishes (Ra .8μm max). This technical capability is critical for high-pressure applications in oil/gas, chemical processing, and marine environments.

EMAR's Valve Machining Process

1. Material Selection: We use 316L/304L stainless steel with full material traceability

2. Precision Turning: Swiss-type lathes create perfect concentricity for valve stems/seats

3. Multi-axis Milling: Complex porting and flange patterns machined in single setup

4. Quality Assurance: 100% dimensional inspection with CMM and pressure testing

Industry-Specific Solutions

Our engineering team collaborates with clients to address:

- Cryogenic valve challenges (-196°C applications)

- Anti-cavitation trim designs

- API 6D/ASME B16.34 compliant components

- Custom surface treatments (electropolishing, PTFE coating)

Partner with EMAR for Your Valve Projects

With 15+ years of CNC machining expertise, EMAR combines German-engineered equipment with ISO 9001-certified processes to deliver stainless steel valves that outperform industry benchmarks. Our end-to-end service includes DFM analysis, rapid prototyping, and batch production with 30-day lead times.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque