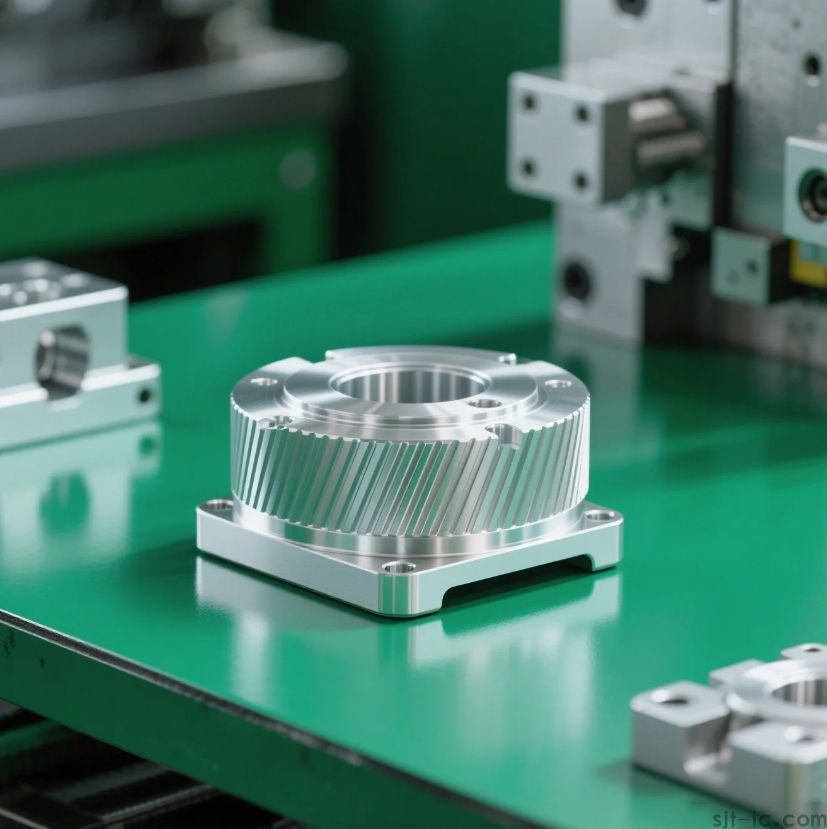

Why has aluminum become the top choice for CNC Machining?

Aluminum, renowned for its lightweight properties, corrosion resistance, and excellent machinability, has emerged as a core material in aerospace, automotive manufacturing, and electronic products. Particularly, the 6061 and 7075 aluminum alloys strike a balance between strength and ductility, ensuring high stability during batch machining 🔥. CNC technology enables precise cutting of complex structures through numerical programming, with tolerances controlled within ±0.1mm, significantly reducing the scrap rate.

Core challenges and solutions for custom non-standard aluminum parts

Non-standard parts need to meet unique design requirements, yet traditional machining often faces issues like dimensional deviations or surface scratches. A phased approach is recommended to address these problems:

1. Design phase: Use simulation software to predict stress concentration points and optimize thin-walled structures.

2. Tool selection: Given aluminum’s adhesive nature, adopt sharp-angle end mills to minimize burrs.

3. Cooling solution: Use high-pressure cutting fluid for flushing and heat dissipation to prevent high-temperature deformation.

💡 Personal perspective: The key to successful non-standard customization lies in early-stage communication — it is essential to clarify the tolerance markings on drawings and application scenarios to avoid rework!

Cost control and efficiency optimization for batch machining

The core demand for batch orders is cost reduction and efficiency improvement. A comparison of three common processes reveals the following:

| Process Type | Time per Piece | Suitable for Batch Size | Compatibility with Surface Treatment |

|--------------|----------------|-------------------------|---------------------------------------|

| CNC Milling | 15 minutes | 500+ pieces | Anodization / Sandblasting |

| Die Casting | 5 minutes | 5000+ pieces | Limited electroplating |

| 3D Printing | 30 minutes | ≤ 50 pieces | Post-processing required (e.g., polishing) |

Although CNC machining takes slightly longer per piece, it is ideal for fast response in small-to-medium batch production and supports integrated molding of multiple materials.

How to select a reliable CNC machining supplier?

⚠️ A supplier’s capabilities directly determine the quality of finished products. Focus on evaluating four key dimensions:

- Equipment precision: Verify whether the supplier is equipped with 5-axis CNC machines and laser detectors.

- Quality control process: Request ISO 9001 certification and samples of full inspection reports.

- Material traceability: High-quality manufacturers will provide original aluminum material quality certificates.

- Delivery cases: Refer to successful projects in similar industries (e.g., automotive parts).

A large number of mature suppliers are concentrated in South China, such as Dongguan and Shenzhen, with some offering urgent order delivery within 3-5 days 📅.

Surface treatment: The key to enhancing aluminum part lifespan and aesthetics

Bare aluminum parts are prone to oxidation, so surface treatment processes should be selected based on application scenarios:

- Anodization: Improves wear resistance, with optional colors (black/silver are most commonly used).

- Sandblasting: Creates a matte texture and conceals machining marks.

- Electroless nickel plating: Suitable for high-corrosion environments (e.g., marine equipment).

✨ Exclusive data: In 2024, 60% of complaints related to aluminum part machining stemmed from inconsistencies between surface treatment and agreed standards — be sure to confirm treatment standards before signing a contract!

Future trends: Intelligent production and green manufacturing

With the advancement of Industry 4.0, CNC machining factories are gradually introducing IoT monitoring platforms to track equipment status and order progress in real time. Meanwhile, stricter environmental requirements have driven the popularization of cutting fluid recycling technology, reducing waste fluid discharge by 90% 🌱. Choosing enterprises with green factory certification ensures more stable long-term cooperation.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque