Hey, do you often struggle with choosing between 3-axis and 5-axis for CNC Machining? Wondering if small-batch orders can even be accepted, and how to pick the right manufacturer? Today, I’ll chat with you about this to hopefully help you out! 😊

▍Why Is 5-Axis Machining Becoming More and More Popular?

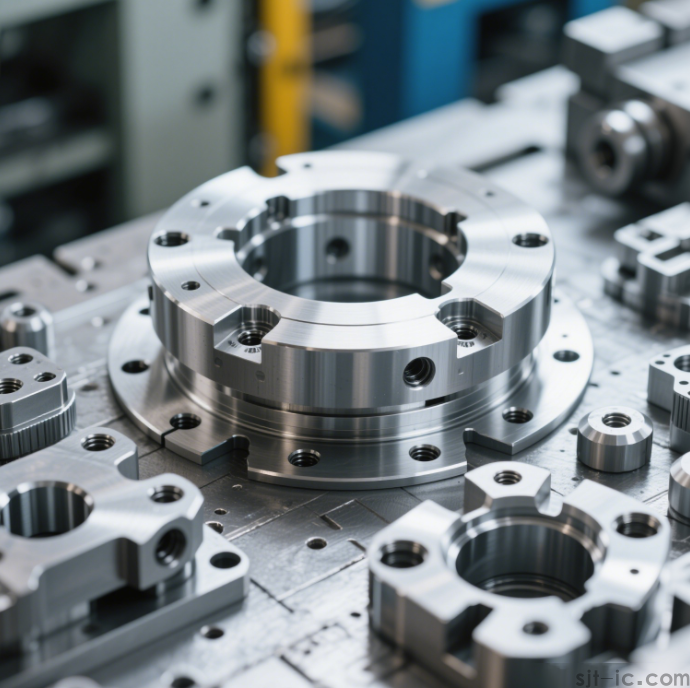

Simply put, 5-axis machining means the machine tool can move in five directions simultaneously—way more flexible than traditional 3-axis! For example, when machining complex curved surfaces or irregular parts, 5-axis gets the job done in one go, no need for repeated clamping, and the precision is still high. I think, especially in high-tech fields like aerospace and medical equipment, 5-axis has almost become a standard.

👉 Core Advantages of 5-Axis Machining:

- Higher Precision: Fewer clamping times mean less error accumulation, with tolerances controllable within ±0.01mm.

- Boosted Efficiency: Complex parts can be processed in a single cut, saving time and effort.

- Stronger Capability: It can handle "dead corners" like deep cavities and chamfers with ease!

However, 5-axis equipment is expensive and its programming is complex, so it’s only suitable for tasks with high precision requirements and complex structures. If you’re working on simple parts, 3-axis is sufficient—no need to waste money!

▍How to Choose for Small-Batch Machining Without Mistakes?

Many people worry that small-batch orders will be rejected, or that the quality will be unstable. But in fact, reliable manufacturers value long-term cooperation and are willing to take small-batch orders! Focus on these key points:

1. Prototyping Capability: Can they produce samples quickly? For instance, some factories offer "3-7 day delivery," and even 1-2 days for rush orders.

2. Process Transparency: Will they clearly communicate the machining steps? A standardized process—from drawing inspection → programming → machining → quality inspection—gives you peace of mind.

3. Material and Surface Treatment Options: Are they familiar with materials like aluminum, stainless steel, and copper? Can they handle post-treatments such as anodizing and sandblasting?

I suggest that for small-batch orders, you must find factories that specialize in "multi-variety, small-batch" production. They have flexible equipment scheduling and strong quality awareness! Don’t go for big factories just to save money—they might ignore you because the batch size is too small 😅.

▍What Synergy Do 5-Axis Machining and Small-Batch Production Create?

Actually, they’re a perfect match! For example, in R&D prototyping or custom non-standard parts, the batch size is usually small but the shapes are complex. 5-axis machining just plays to its strengths here—it balances precision and efficiency, and even saves on mold costs!

✅ Suitable Scenarios:

- New product prototype manufacturing

- High-precision custom parts (e.g., medical instrument accessories)

- Trial production stages with expensive materials

▍Personal Insights and Recommendations

I’ve interacted with many processing factories and found that 5-axis machining and small-batch orders are often a "litmus test" for high-quality customers. Only manufacturers with solid technology and good service dare to take on such orders! So, don’t just compare prices—pay more attention to these aspects:

- Case Experience: Have they worked in similar industries (e.g., automotive, electronics, medical)?

- Quality Inspection Process: Do they have 2D or 3D measuring equipment? Can they provide data reports?

- Cooperation Model: Will they sign a non-disclosure agreement? Can they accept customizations based on drawings or samples?

Finally, a reminder: Whether you choose 5-axis or 3-axis, clearly communicating your needs is always the first step! Spell out details like drawings, materials, precision requirements, and surface treatments—this will minimize the risk of mistakes 🚀.

Do you need me to further polish this English translation to be more formal (for business negotiations) or more concise (for product brochures)? I can also add professional terminology annotations if you need to share it with overseas technical teams.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque