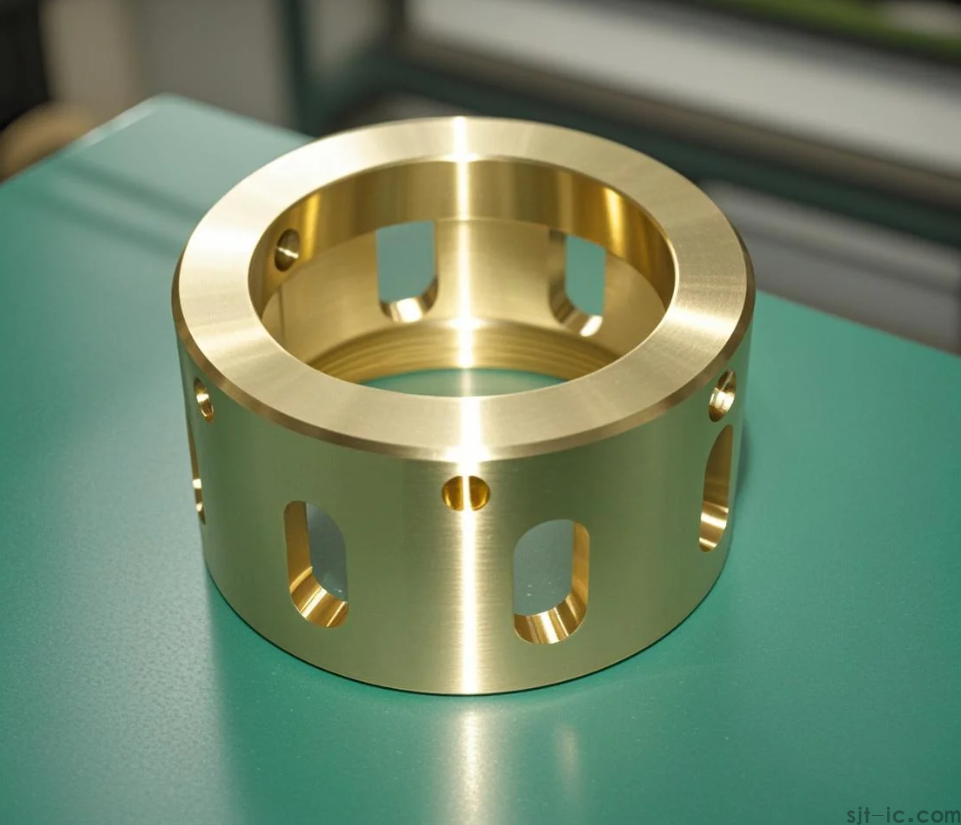

1. Tool Selection Matters for Roughing Copper Workpieces

Anyone with CNC experience knows that the roughing stage has a huge impact on efficiency. When roughing copper workpieces, try to avoid using high-speed steel (HSS) tools as much as possible—they wear out quickly, and you can’t run them at high speeds either. Instead, fly cutters or carbide tools are more cost-effective here: they are more durable and can handle larger cutting depths. Simply put, choosing the right tool makes the work easier and saves a lot of time spent on tool changes!

2. Layered Machining Is Essential for Tall Copper Workpieces

When dealing with tall copper workpieces, don’t try to machine them from top to bottom with a single tool! The stable and reliable approach is layered machining—using tools of different lengths to gradually rough the workpiece. This method not only prevents tool vibration and chatter but also ensures uniform machining allowance for each layer. That makes sense, right?

3. Flat-End Mills Are the First Choice for Flat Surface Machining

When machining flat surfaces, remember to use flat-end mills instead of ball-end mills. Flat-end mills have a larger contact area, which ensures more stable cutting and much higher efficiency. Ball-end mills, on the other hand, are better suited for curved surface machining. From the editor’s perspective, this is about "each tool doing its own job": this way, every tool plays its maximum role, and you also save a lot of machining time!

4. For Corner Cleaning: Measure the Radius First Before Cutting

Corner cleaning on copper electrodes is a delicate task. Before cleaning the corners, you must first check the size of the corner radius (R-radius). Then, select a ball-end mill of the appropriate size based on this radius. If you choose a tool that’s too large, you won’t be able to clean the corners thoroughly; if the tool is too small, it will easily break—wasting both time and material. So, taking an extra minute to measure will never go wrong!

5. Make Good Use of Tapered Tools for High Efficiency on Tapered Features

If the workpiece has integer tapers (e.g., some positioning pins or cylindrical bosses with tapers), don’t hesitate—use a tapered tool directly for machining. This method offers high efficiency and good precision, saving you a lot of trouble. The editor has noticed that some people always try to make do with ordinary tools, but this ends up taking more time. Why go through that hassle?

Personal Insights and Recommendations:

CNC copper machining faces two major challenges: the material is soft and prone to tool adhesion. Here are some tips for operation:

- Spindle Speed and Feed Rate: Copper has good machinability, so you can moderately increase both the spindle speed and feed rate.

- Spark Gap Reservation: When machining copper electrodes, set the spark gap (reserved allowance) properly. For roughing electrodes, the gap is usually 0.2–0.5mm; for finishing electrodes, it’s 0.05–0.15mm.

- Tolerance and Stepover: For finishing copper electrodes, it’s appropriate to set the tolerance between 0.005–0.02mm and the stepover between 0.05–0.3mm.

- Maintenance and Inspection: Regularly maintain the machine tool, and carefully check the program simulation before machining to avoid overcutting and tool collisions.

In short, mastering these methods will make CNC copper machining twice as effective with half the effort! Hope this helps you.

Do you need me to adjust the translation of specific technical terms (such as optimizing expressions for "spark gap" or "stepover" to align with international CNC Machining conventions) or create a bilingual glossary of core CNC copper machining terms for your reference?

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque