Oh, when it comes to finding a CNC Machining platform, does it feel a bit overwhelming? Especially when you need to machine those small and precision parts, you’re even more worried about choosing the wrong factory, which will delay work and waste money 😫. I often deal with these platforms, so today I’ll talk about how to pick a reliable platform that specializes in CNC machining of small parts!

First, Figure Out What You Need

Choosing a platform isn’t just picking one randomly; you need to sort out your own needs first ✍️. It’s like going out to eat—you have to know if you want spicy food or sweet food first!

Clarify the material: Do you need to machine metal, plastic, or some special composite material? Different platforms may be good at different materials.

Determine the precision requirement: Small parts often have stricter precision requirements. You need to have a clear idea, such as the tolerance level in micrometers you need to achieve.

Estimate the quantity: Is it a small-batch prototype, or do you need long-term stable supply? This also directly affects your choice.

Set the budget and timeline: How much money you plan to spend and when you need the parts—these practical factors must be considered in advance.

Focus on Examining the Platform’s "Hard Power" and "Soft Power"

Once your needs are clear, the next step is to keep your eyes open and check the platform itself. From my perspective, the following aspects are particularly important:

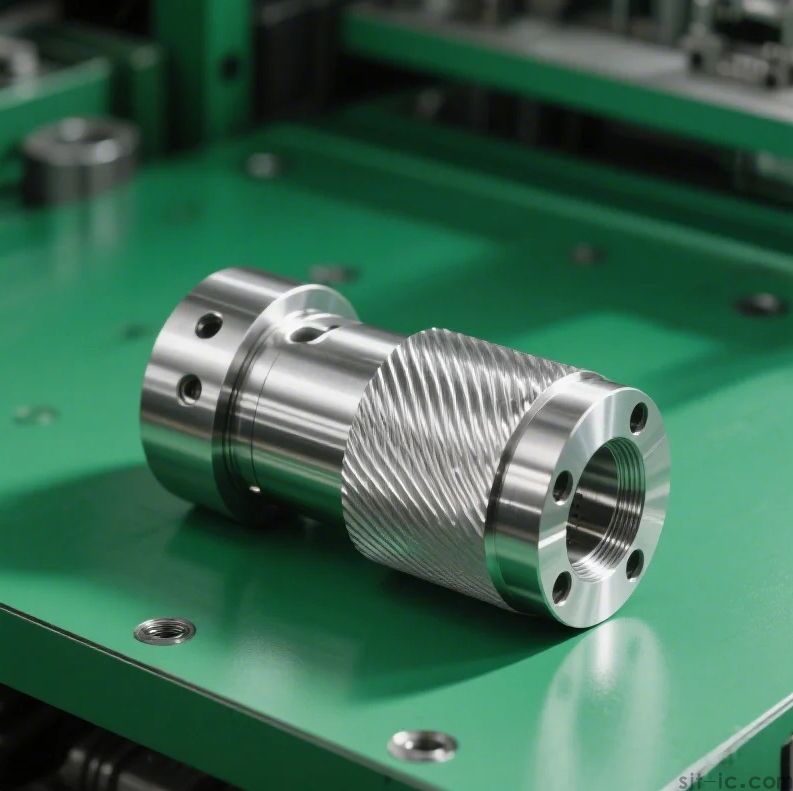

Professionalism of equipment and technology: Machining precision small parts relies heavily on high-precision CNC equipment, such as 5-axis machining centers. Ask about the brand of machine tools they use and the precision they can achieve. Capable platforms may even use special processes like laser machining and Electrical Discharge Machining (EDM) to handle complex microstructures.

Strictness of quality control system: Having good machines isn’t enough; there must also be a strict quality management system. Check if they have quality system certifications like ISO 9001. Monitoring during the machining process—such as monitoring cutting sounds and parameters—and post-processing inspections using professional equipment like coordinate measuring machines are key to ensuring precision.

Persuasiveness of experience and cases: If a platform has many successful cases of small parts with complexity similar to your product, its reliability will be much higher. Feel free to ask them to provide samples or case pictures from the past.

Adequacy of after-sales service: After machining is completed, technical support and response speed for problems are also important. Finding a platform that allows timely communication and can solve problems quickly will save you a lot of trouble.

Price and Service: How to Compare Wisely

Price comparison is certainly necessary, but you can’t just look at who offers the lowest price ❌. The saying "you get what you pay for" is very common in the machining industry.

Ask several target platforms to provide detailed quotations, and check if material costs, machining fees, surface treatment fees, mold fees (if needed), etc., are all clearly listed to avoid hidden charges later.

Comprehensive comparison: Weigh the price quoted by each platform against the equipment level, quality assurance, after-sales service they can provide. Sometimes, spending a little more money to get stable quality and peace of mind is more cost-effective in the long run.

Cases and Reputation: Listen to What Others Say

As the saying goes, "A peddler praises his own goods," so you also need to see what others say about them.

Proactively ask to see cases: Especially cases similar to your product type and precision requirements, as these are the most illustrative.

Inquire through multiple channels: Ask friends in the industry, or check user reviews on industry forums and B2B platforms (although direct information isn’t provided in the search results, this is a common practice). Real user feedback is often very valuable for reference.

Small-Batch Trial Order: Practice Is the Best Test

No matter how much preparation you do in advance, it’s not as good as placing a real small-batch order to test the waters 🔥. Use a small-batch order to test the platform in terms of:

Product quality: Whether the finished parts meet your requirements.

Delivery time: Whether they can deliver on time.

Communication efficiency: Whether the communication during the process is smooth.

Problem handling: If problems arise, what their attitude and speed are like in solving them.

If the trial order experience is good, then you can consider establishing a long-term cooperation. Long-term cooperation usually also allows you to negotiate for more favorable prices and higher priority in services.

My Exclusive Insight:

According to some industry data, for CNC machining platforms specializing in small precision parts, the cost proportion of their equipment investment in precision maintenance and dynamic compensation systems (such as grating scale closed-loop control) is often more than 25% higher than that of ordinary platforms. These "invisible" investments are precisely the key to ensuring the quality of the small parts in your hand. So, sometimes don’t just focus on the unit price; ask more about technical details, and you’ll get a better understanding of the platform’s true capabilities.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque