Why does your new energy vehicle (NEV) run smoothly and durably? 🤔 The secret lies entirely in CNC precision machining! I’ve noticed that many manufacturers are competing fiercely in terms of batteries and intelligent systems, yet they overlook the manufacturing of core components—actually, a precision deviation of just 0.01mm could affect range and safety! Today, let’s dive into the technical details that top factories don’t want you to know! 👇

👉 What Special Requirements Does NEV Manufacturing Impose on CNC Machining?

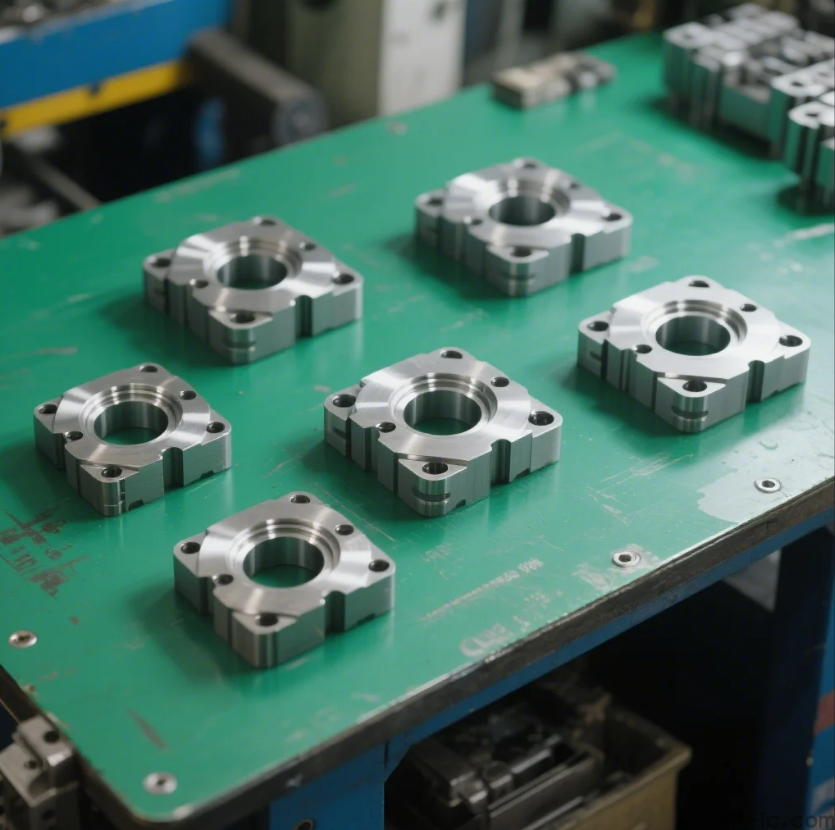

Compared with traditional fuel vehicles, NEVs place greater emphasis on lightweight design and heat dissipation efficiency! For example, motor housings must be both thin-light and sturdy; otherwise, power output will be compromised. Battery module brackets need precision heat dissipation holes to prevent overheating 🔥.

I once worked with a company that used aluminum alloy die-casting combined with 5-axis machining, reducing part weight by 30% directly! They also improved heat dissipation efficiency by 25% through microchannel design—those are some solid results, right?

👉 Analysis of the Five Key Technologies

1. Material Selection: NEVs commonly use aluminum alloys (for lightweighting), stainless steel (for structural parts), and titanium alloys (for high-strength components). For instance, Tesla’s motor housings are made of 6061 aluminum alloy, and temperature must be controlled during machining to prevent deformation!

2. Precision Machining Processes:

- 5-Axis Machining: Enables complex curved surfaces to be completed in a single setup, minimizing errors! When machining scroll plates, for example, precision can reach ±0.001mm.

- Turn-Mill Composites: Machines like Japan’s OKUMA can perform turning, drilling, and milling in one go, eliminating 3 separate setup steps.

3. Quality Control: High-end factories all use coordinate measuring machines (with a precision of 0.0009mm) and roughness testers—I’ve personally seen workers conduct sampling inspections for each batch, and entire batches are scrapped if test data fails!

4. Smart Manufacturing Systems:

- Full-Process CAD/CAM Collaboration: Machining paths are simulated in advance, allowing 92% of defects to be identified before production starts.

- Adaptive Machining: AI automatically adjusts parameters based on tool wear, avoiding mid-production shutdowns.

5. Surface Treatment: NEV parts often require anodization (for corrosion resistance) or micro-arc oxidation (for enhanced hardness)—don’t underestimate this final step; it directly impacts service life!

👉 Comparison of Industry Application Cases

| Part Type | Pain Points of Traditional Machining | Innovative CNC Solutions | Performance Improvement |

|---------------------|---------------------------------------|-----------------------------------|-----------------------------------|

| Motor Housing | Heavy weight, poor heat dissipation | 5-axis milling + microchannel design | 30% weight reduction, 25% better heat dissipation |

| Battery Module Bracket | High assembly error rate | Turn-mill composite one-piece forming | Leakage rate < 0.3% |

| Gearbox Components | Loud noise, short service life | Precision boring + mirror polishing | 40% noise reduction |

👉 My Advice: How to Choose a Reliable Machining Factory?

If you’re a corporate purchaser or technician, keep these points in mind:

- Check Equipment: The factory must have 5-axis machines (e.g., Japan’s Mazak, Germany’s DMG MORI) and precision testing instruments.

- Ask About Experience: Prioritize factories that have served NEV brands like BYD and Leapmotor (with proven experience in NEV projects).

- Test Samples: Request DFM (Design for Manufacturability) analysis—a free report can reveal the factory’s professionalism!

Never choose a small unqualified workshop just to save money! A friend of mine opted for an uncertified factory to cut costs, only to have battery bracket hole positions deviate by 0.5mm. The entire vehicle required rework, resulting in a million-yuan loss 😭…

Final Thought: CNC machining is not just about "cutting"; the NEV era demands more process integration—such as using 3D printing for prototypes, CNC for precision finishing, and intelligent quality inspection. The future trend will definitely be nanoscale precision + full automation. If our factories don’t upgrade their equipment soon, they’ll truly be left behind! 🚀

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque