😮 Are you struggling to find reliable CNC Machining suppliers that can handle both small orders and deliver precision results? You're not alone! Many purchasing managers and engineers face this exact dilemma. Let's dive straight into solving your core problem.

🤔 What Exactly Should You Look For in a Precision CNC Supplier?

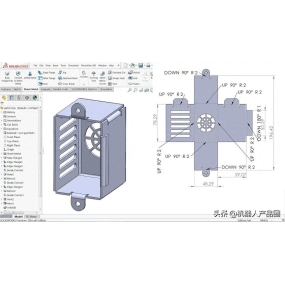

When we're talking about precision CNC machining, the first thing that comes to mind is accuracy. But is that really all there is to it? From my experience working with multiple suppliers, I've found that while technical specifications are crucial, there's more to the story.

Many suppliers claim to offer precision services, but what they actually deliver might surprise you. The truth is, precision isn't just about the machines - it's about the people operating them and the quality control processes in place. I've seen cases where two suppliers using identical equipment produced vastly different results.

Key considerations:

- Measurement and inspection capabilities

- Operator experience and training

- Quality assurance documentation

- Material traceability systems

💡 How to Evaluate Small Batch Suppliers Effectively

Finding suppliers for small batch CNC machining can be particularly challenging. Many larger suppliers either don't accept small orders or charge premium prices. But here's the thing - small batches can actually reveal a supplier's true capabilities.

In my observation, suppliers who excel at small batches often have better flexibility and problem-solving skills. They're used to handling diverse projects and can adapt quickly to changes. However, I must admit there's one area where I'm not entirely clear - why some suppliers struggle with consistency across small batches while others maintain perfect quality.

Practical evaluation tips:

- Ask for sample parts from previous small batch projects

- Check their setup and changeover procedures

- Inquire about their pricing structure for small quantities

- Verify their communication responsiveness

🚀 Balancing Quality and Cost in Supplier Selection

This is where things get tricky. We all want the best quality at the lowest price, but is that realistic? From what I've seen in the industry, there's usually a trade-off involved.

Some suppliers might offer lower prices but cut corners on quality control. Others might deliver exceptional quality but at costs that blow your budget. The sweet spot is finding suppliers who understand your specific needs and can optimize their processes accordingly.

Though it's worth mentioning that I've noticed an interesting pattern - sometimes mid-priced suppliers deliver better overall value than both cheaper and more expensive options. This might suggest that pricing alone isn't always the best indicator of value.

Cost-quality balance strategies:

- Request detailed breakdowns of pricing

- Compare quality certifications across suppliers

- Evaluate their problem-solving approaches

- Consider long-term partnership benefits

🎯 My Personal Approach to Supplier Verification

Over the years, I've developed a method that seems to work pretty well. It involves looking beyond the usual checklist and paying attention to some often-overlooked factors.

For instance, I always check how suppliers handle unexpected challenges. Do they communicate proactively? Are they transparent about delays or issues? These factors can be more telling than their equipment list.

One thing I've learned the hard way: don't underestimate the importance of cultural fit. A supplier might have all the right credentials, but if your teams don't communicate well, the partnership is likely to struggle.

My verification checklist:

- Site visit observations (when possible)

- Reference checks with current clients

- Evaluation of their technical support responsiveness

- Assessment of their continuous improvement mindset

🌟 Based on my experience working with various manufacturing partners, I've noticed that the most successful partnerships often come from suppliers who view themselves as problem-solvers rather than just part producers. They ask questions about your application, suggest design improvements, and truly understand that they're contributing to your final product's success.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque