Struggling with inconsistent parts from your CNC machine? 😩 You're not alone. Many workshop managers and engineers face the headache of precision drift, especially with smaller, more intricate components. It hits right where it hurts – wasted materials, delayed deliveries, and frustrated clients. Let's dive straight into the core of how to guarantee small CNC Machining accuracy and unpack a practical CNC machining accuracy assurance scheme that you can start applying today.

What's the Biggest Hurdle for Small Part Precision?

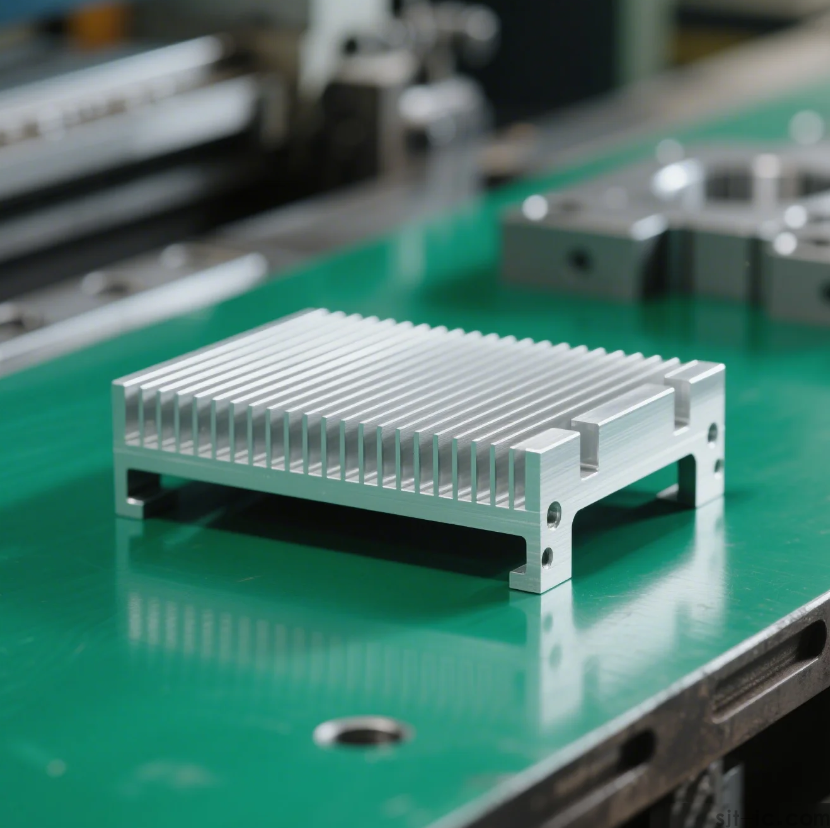

First things first, why do small parts pose such a big challenge? The main culprit often lies in vibration and thermal expansion. When you're machining something tiny, even the slightest tremor or temperature shift can throw dimensions completely off. It's not just about the machine being "precise" on paper; it's about how you manage the entire process. I've seen shops obsess over buying the most expensive machine, only to overlook simple fixturing – that's a classic misstep.

Building Your CNC Accuracy Assurance Scheme from the Ground Up

An effective scheme isn't a single magic trick. It's a system. Think of it like a chain – every link needs to be strong.

1. Machine Foundation and Calibration: It all starts here. A machine that isn't properly leveled or has worn ball screws will struggle. Regular calibration is non-negotiable. But, is calibration alone the ultimate solution? Perhaps it only hints at a deeper need for comprehensive maintenance.

2. Tooling Selection and Management: Using the wrong tool for a small, detailed feature is like using a sledgehammer to crack a nut. For small parts, shorter, stubbier end mills resist deflection much better. Keep a tight log of tool life – a dull tool doesn't cut, it just rubs and heats up.

3. Workholding is Everything: This is arguably the most critical step for small parts. If the workpiece can move even a micron, you've lost. Vacuum chucks, custom jigs, or specialized vises designed for micro-machining can make a world of difference. I'm a huge fan of modular fixturing systems for their versatility.

Mastering the "Invisible" Factors: Heat and Vibration

Okay, you've got the basics down. Now for the subtle arts. Heat management is a beast. The cutter, the workpiece, and the machine itself all generate heat. Using coolant effectively is key, but the specific flow rate and mixture for optimal heat dissipation in small-scale operations is something I'm still experimenting with – the exact science can get pretty nuanced.

Then there's vibration dampening. Apart from using balanced toolholders, consider the machine's environment. Is it on a isolated foundation? Are there other heavy machines nearby causing vibrations? Sometimes, the fix is as simple as adding vibration-damping pads.

Your Practical Checklist for Daily Operations

Let's get practical. Here’s a quick list I use and recommend:

- ✅ Pre-job Check: Verify machine calibration, warm-up the spindle, and inspect tools.

- ✅ In-process Monitoring: Use touch probes for in-process inspection. Don't just hope for the best; verify.

- ✅ Post-process Audit: First-article inspection is a must. And don't just check one dimension; check the critical ones that customers care about most.

Following this list religiously has saved my team from countless potential rejects. However, it's worth mentioning that even with a perfect checklist, material inconsistencies from batch to batch can sometimes throw a wrench in the works. It's a variable we constantly have to watch for.

A Final Thought from the Workshop Floor

Precision machining, especially with small parts, is a blend of rigid science and subtle art. While the schemes and checklists provide a solid framework, the intuition you develop from watching thousands of parts come off the machine is invaluable. It's that gut feeling when something "sounds" or "looks" wrong. That human element, paired with a robust system, is the ultimate accuracy assurance scheme you can't really buy, only build through experience. 🛠️

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque