Are you struggling to find reliable steel CNC Machining parts that meet your exact needs? 😓 Many buyers face issues like inconsistent quality or high costs, but what if you could get high-precision, custom parts without the hassle? In this article, we'll dive into the core questions behind high precision and customization, sharing practical insights to help you make smarter decisions. Let's explore how these aspects can transform your procurement process! 🚀

What Is High Precision Steel CNC Machining and Why Does It Matter?

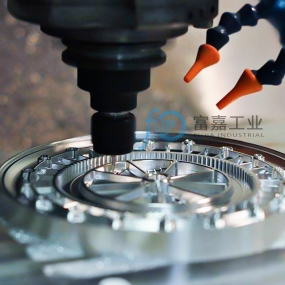

High precision steel CNC machining refers to using computer-controlled tools to shape steel parts with extremely tight tolerances—think of it as crafting components with minimal errors. This is crucial for industries where even a tiny mistake can lead to big problems, like in automotive or aerospace applications. For example, if a part is off by just a millimeter, it might cause machinery to fail. From my experience, many businesses overlook this, but investing in high precision can save you from costly reworks down the line. However, it's worth noting that achieving such accuracy isn't always straightforward; factors like material hardness or machine wear can introduce variations. So, while high precision often leads to better performance, it might not be the sole solution for every scenario—sometimes, a balance with cost is needed. Personally, I've seen cases where focusing too much on precision drove up expenses without proportional benefits, so it's wise to evaluate your specific requirements first. 🔧

How Can Custom Steel CNC Machining Parts Solve Your Unique Problems?

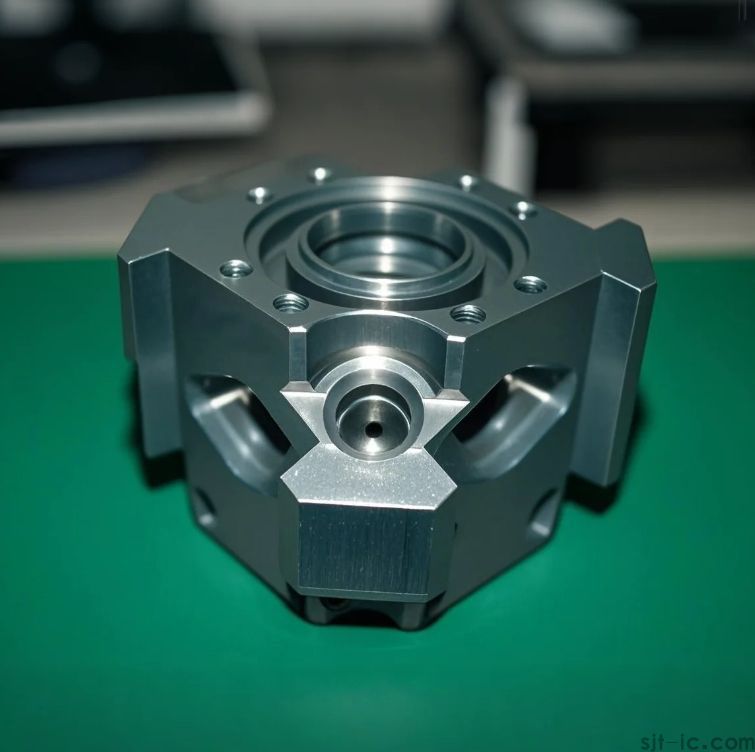

Custom steel CNC machining parts are tailored to your exact specifications, whether it's a unique shape, size, or function. This is perfect for projects where off-the-shelf options just don't cut it—like designing a specialized component for industrial equipment. Imagine you're a procurement manager dealing with tight deadlines; custom parts can streamline your supply chain by reducing the need for modifications. But here's the thing: customization isn't a magic bullet. It often involves longer lead times and higher upfront costs. In my view, though, the long-term advantages, like improved efficiency and fewer compatibility issues, often outweigh these drawbacks. I recall a project where custom parts helped a client reduce assembly time by 30%, but we had to navigate some design challenges along the way. If you're considering this, start by clearly defining your needs to avoid over-engineering. 💡

What Are the Key Factors to Consider When Choosing These Services?

When selecting a provider for high precision or custom steel CNC machining, keep these points in mind:

- Quality checks: Look for suppliers who perform rigorous inspections—this can prevent defects and ensure consistency.

- Communication: A good partner will discuss your requirements in detail, helping you avoid misunderstandings.

- Cost vs. value: Don't just go for the cheapest option; sometimes, paying a bit more for reliability pays off in the long run.

From my perspective, I've found that building a strong relationship with your supplier can lead to better outcomes, like faster turnaround times. But, I'll admit, the exact impact of supplier loyalty on pricing is something I'm still figuring out—it might vary based on market conditions. Overall, focusing on these factors can help you achieve a smoother experience. 👍

How Do High Precision and Customization Work Together in Real Applications?

Combining high precision and customization in steel CNC machining can lead to exceptional results, such as creating parts that fit perfectly in complex assemblies. For instance, in manufacturing, this duo allows for components that not only meet strict standards but also adapt to unique design constraints. I've seen this in action with clients who needed parts for automated systems; the precision ensured reliability, while customization addressed space limitations. That said, it's not always a seamless process—sometimes, trade-offs arise, like when tight tolerances limit design flexibility. But in general, this combination can boost productivity and reduce waste. If you're planning a project, consider how these elements complement each other to maximize your investment. 🛠️

In the end, opting for high precision and custom steel CNC machining parts can significantly enhance your operations, but it's essential to weigh the pros and cons based on your situation. From my observations, businesses that take a thoughtful approach tend to see better returns—so don't rush the decision! 😊

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque