Hey there, fellow engineers and procurement managers! 😊 Are you tired of dealing with inconsistent precision or skyrocketing costs in complex profile CNC Machining? You're not alone—many of us face these headaches daily. In this post, I'll dive into the core questions behind accuracy control and cost optimization, sharing practical tips and personal insights to help you navigate these challenges. Let's get started and explore how to tackle these issues step by step! 🚀

What is Complex Profile CNC Machining Accuracy Control and Why Does It Matter?

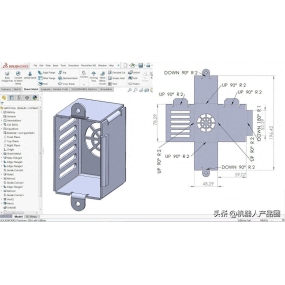

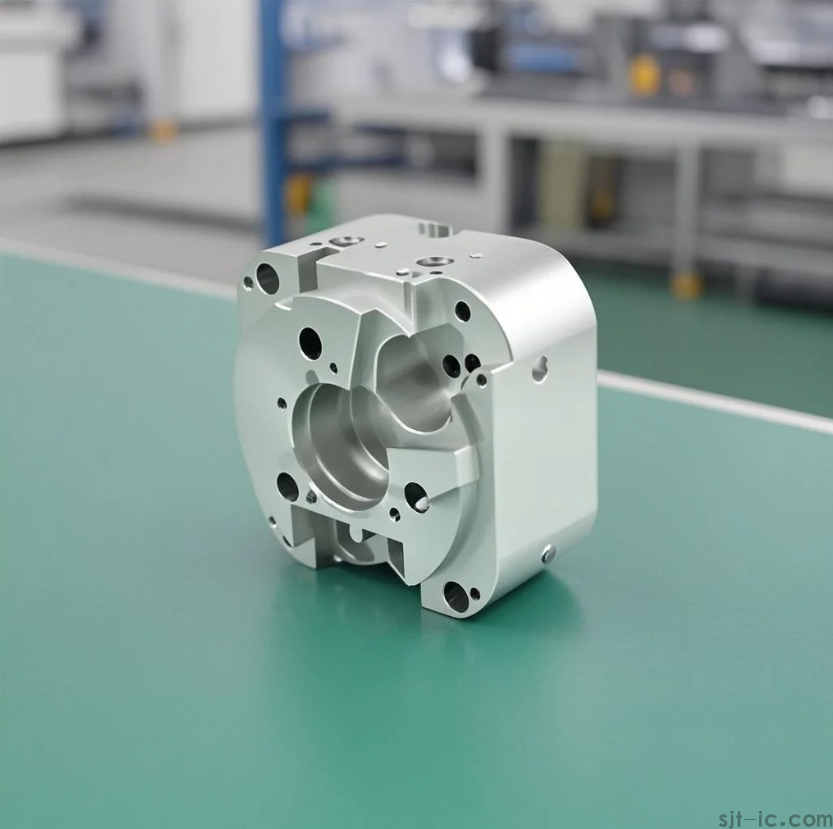

When we talk about accuracy control in complex profile CNC machining, it's all about ensuring that every cut, drill, and shape matches the design specs perfectly. Think of it like baking a cake—if the measurements are off, the result is a mess! For instance, in my experience, even a tiny error in tool path can lead to parts that don't fit together, causing delays and wasted materials. But here's the thing: while high precision seems straightforward, it often involves balancing factors like machine calibration and material behavior. I've found that using digital monitoring tools can help, but honestly, the exact way vibrations affect accuracy still puzzles me sometimes—it's an area where more research is needed. So, if you're struggling with this, focus on regular machine checks and operator training. On the flip side, don't forget that over-precision might drive up costs, so it's a trade-off we have to manage.

How Can We Optimize Costs in Complex Profile CNC Machining?

Cost optimization isn't just about cutting corners—it's about smart choices that save money without sacrificing quality. From my work, I've seen that many companies overspend on raw materials or inefficient workflows. For example, by reusing tooling where possible and optimizing cutting speeds, you can reduce waste and energy use. However, it's not always black and white; although these methods work, they might not suit every material type. A key point I've realized is that investing in better software for simulation can prevent costly errors down the line. But wait, there's a catch: the initial setup for such systems can be pricey, so it's worth weighing the long-term benefits. Personally, I think starting with small changes, like batch processing, can make a big difference. Just remember, cost control is a continuous process, not a one-time fix.

What Are the Common Challenges in Balancing Accuracy and Cost?

Balancing accuracy and cost is like walking a tightrope—it requires focus and adaptability. In my view, the biggest hurdle is when tight budgets force compromises on precision, leading to rework and higher expenses later. For instance, I've dealt with projects where rushing to meet deadlines resulted in inaccurate cuts, and we had to redo entire batches. That said, it's possible to find a middle ground by prioritizing critical dimensions and using cost-effective materials. Here's a tip: involve your team in brainstorming sessions to identify waste areas. But let's be real, sometimes external factors like supply chain issues throw a wrench in the works, and that's where flexibility comes in. Overall, I believe that a proactive approach, combined with ongoing training, can help you strike that balance effectively.

Personal Insights and Final Thoughts

After years in the field, I've come to see that complex profile CNC machining is as much an art as a science. While we've covered accuracy and cost, there's always more to learn—like how emerging technologies might change the game. For example, I'm excited about AI-driven optimizations, but their full impact is still unclear. In the end, my advice is to stay curious and collaborative. If you try out these ideas, I'd love to hear how they work for you! Keep experimenting and sharing—it's how we all improve together. 👍

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque