Hey there! 👋 Are you a project manager or engineer feeling stuck trying to find a trustworthy partner for your precision metal parts? You're not alone. I've been there, scrolling through countless suppliers, wondering who actually delivers on their promises of quality and consistency. The wrong choice can lead to costly delays and headaches. Let's break down how you can make a smarter decision. 🤔

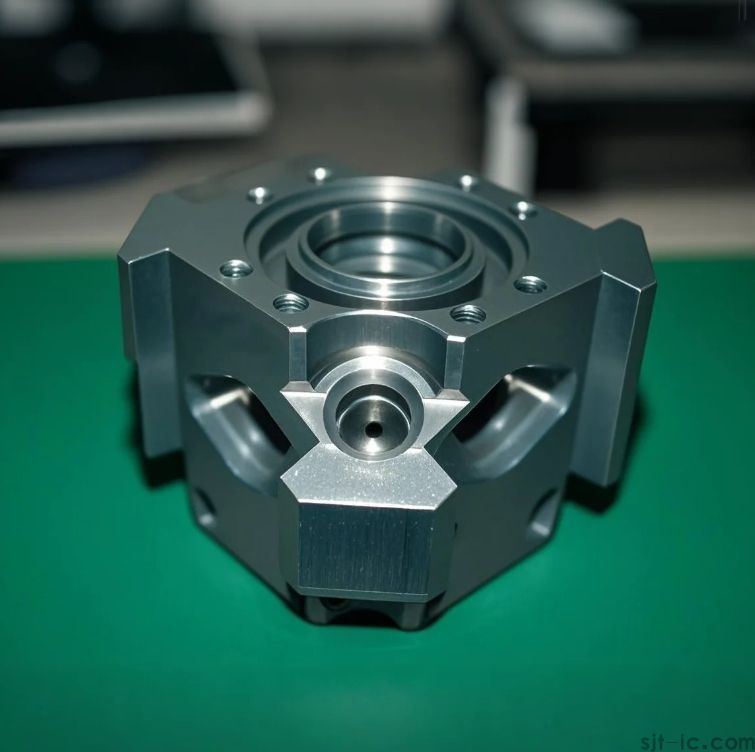

What Exactly is "Precision" in CNC Stainless Steel Machining?

First things first, let's clear this up. When we talk about "precision," we're not just throwing around a fancy word. It means the ability to consistently produce parts with extremely tight tolerances – think dimensions that are accurate to within a few human hairs! For stainless steel, this is tricky because the material can be tough and move a bit during cutting. A true precision supplier has the right machines and expertise to control this. I often find that shops claiming high precision might be stretching the truth a bit. Their actual capability, perhaps, depends on the specific part geometry, a detail that's not always clear upfront.

Key Factors You MUST Consider (Beyond the Price Tag) 💡

Look, I get it. Price is important. But it shouldn't be the only thing. Here’s what I always check:

1. Machine Technology and Calibration: Are their CNC machines modern and well-maintained? Old machines simply can't hold tight tolerances over time.

2. Experience with Your Material: Not all stainless steel is the same. A supplier experienced with 304 or 316L might struggle with harder grades like 17-4PH. Ask them about their specific experience!

3. Quality Control Processes: Do they just do a final check, or do they monitor quality at every step? This is a huge difference maker.

4. Communication and Service: Can you easily get updates? A reliable partner acts like an extension of your own team.

Red Flags: When to Walk Away 🚩

Over the years, I've learned to spot a few warning signs. Be cautious if a supplier:

• Is vague about their inspection equipment (e.g., "Yeah, we have CMMs" but can't describe how they use them).

• Promises an unrealistically fast turnaround for complex parts. Quality takes time.

• Is unwilling to provide a detailed breakdown of their costs. Transparency is key.

• Avoids questions about their team's experience level. The people operating the machines matter most!

A Practical Step-by-Step Approach for Vetting

Okay, so how do you actually do this? Here's a method I frequently use:

Step 1: Shortlist based on technical capability. Can they handle the size, material, and tolerance your part requires?

Step 2: Initiate a conversation. Gauge their responsiveness and willingness to understand your needs. It's not just about sending a quote.

Step 3: Request a sample or prototype run. This is the best way to test the waters. The cost of a small sample is worth the long-term assurance.

Step 4: Audit their quality reports. If possible, ask to see documentation from a previous job. It tells you a lot about their standards.

That said, the exact mechanism for how communication quality translates to final part quality is something I'm still figuring out, but the correlation seems strong in my experience.

My Personal Takeaway

Finding a great CNC stainless steel fabrication supplier is more about building a relationship than just buying a service. The cheapest option often ends up being the most expensive when you factor in reworks and project delays. Look for a partner who asks questions, points out potential issues in your design, and seems genuinely invested in your project's success. That kind of collaboration is, in my view, the real secret to getting top-quality precision parts. Hope this helps you on your search! 👍

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque