Hey there, fellow engineers and procurement pros! 👋 Ever been stuck in that frustrating loop? You need just 50 pieces of a custom aluminum bracket, or maybe 200 units of a precision stainless steel fixture for a pilot run. You contact the big guys, and they either give you the cold shoulder or hit you with a quote that makes your project budget weep. Sound familiar? You're not alone. This is exactly the pain point where small batch CNC metal parts machining shines. But what is it really about, and how do you navigate it to get quality parts without the headache? Let's dive in.

What Exactly is Small Batch CNC Machining?

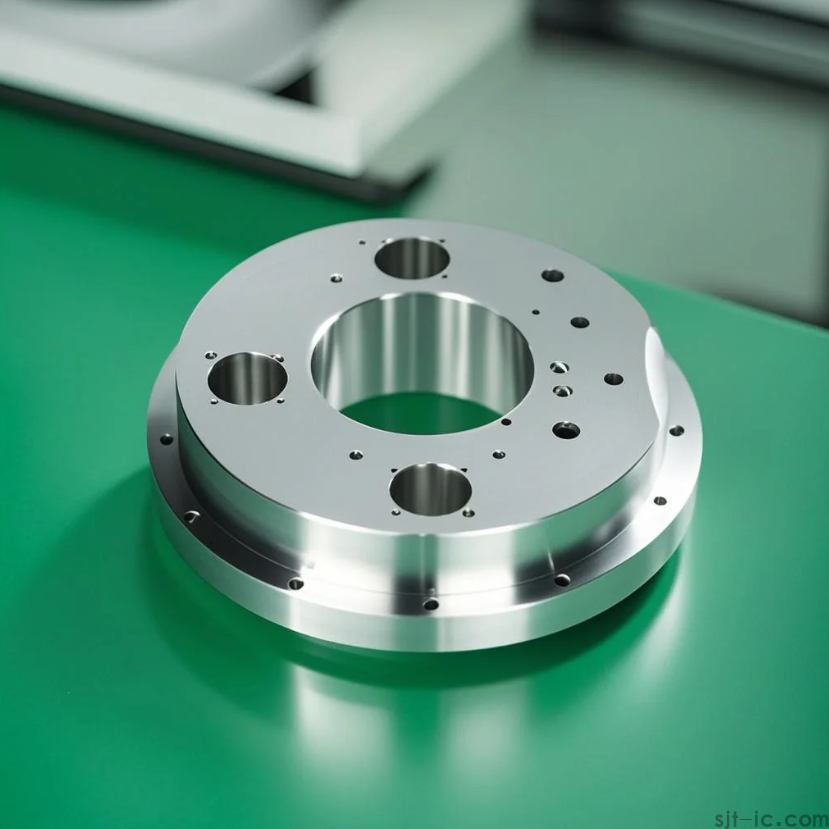

Simply put, it's the production of a limited number of metal parts using Computer Numerical Control (CNC) equipment. We're talking quantities from as low as 1 piece for a prototype up to a few hundred, sometimes even a thousand, depending on the part's size and complexity. It's not mass production; it's flexible, on-demand manufacturing. The core idea is to bridge the gap between one-off prototyping and high-volume orders. So, when you're in the stage of design verification, market testing, or supporting a limited product launch, this is the service you're looking for.

Why Choose Small Batch Machining? The Real Deal.

You might wonder, why not just go with traditional methods for small orders? Well, here's the deal:

✅ Cost-Effectiveness (Really!): While the per-part cost is higher than mass production, the total upfront investment is drastically lower. No need for expensive, dedicated molds or tooling. You pay mostly for machine time and material, which is perfect for managing cash flow. Think of it as 'I often use this strategy' to control financial risk in new projects.

✅ Speed & Agility: Need parts yesterday? Small batch shops are typically set up for quick turnarounds. Digital files go straight to the machine, slashing lead times from weeks to days. This agility is gold for beating competitors to market or iterating designs rapidly.

✅ High Quality & Consistency: CNC machining is inherently precise. Even for 50 parts, each one will be virtually identical, holding tight tolerances. This reliability is crucial for functional testing and ensuring your assembly line doesn't get jammed by bad parts.

✅ Material Freedom: From common aluminum and steel to exotic alloys like titanium or brass, you can prototype and produce in the exact material you plan to use for full-scale production. This gives you true performance data.

It's not all sunshine. The challenge often lies in finding a partner who treats your small order with the same seriousness as a big one. Communication gaps, hidden fees, and quality hiccups can happen. So, what should you do then? Let's look at how to pick the right service.

How to Pick a Reliable Small Batch Machining Partner?

This is where the rubber meets the road. You don't want to be just another "small order." Here’s what to watch for:

🔍 Look for Specialization: Some shops openly cater to prototypes and low-volume work. Their entire process is streamlined for it. Check their website content and case studies.

🔍 Communication is King: From the first quote request, gauge their responsiveness and willingness to discuss your design (Design for Manufacturability advice). A good partner asks questions to save you cost and trouble.

🔍 Transparency in Pricing: A clear, detailed quote that breaks down costs (material, machine time, setup, finishing) is a good sign. Beware of suspiciously lowball offers—they often cut corners.

🔍 Capability Match: Do they have the right machines (3-axis, 5-axis?) and experience with your specific material? Can they provide the surface finishes (anodizing, plating) you need?

Following these points, you can effectively filter and find a service that aligns with your needs for quality and professionalism.

A Quick Peek into the Process (So You Know What's Up)

Understanding the basic workflow helps you set realistic expectations:

1. You Provide the 3D Model: Usually a STEP or IGES file. Ensure it's clean and finalized.

2. Quote & Review: The shop analyzes your file, suggests optimizations if needed, and provides a quote and timeline.

3. Production: They program the CNC machines, set up the job, and start cutting metal.

4. Post-Processing & QC: Parts are deburred, finished (if specified), and inspected against your drawings.

5. Delivery: Packed securely and shipped to your door.

This streamlined process perhaps indicates that with the right partner, complexity can be made simple.

Ready to Get Your Project Moving?

Navigating the world of small batch machining can be smooth sailing with a competent crew. It's about finding that balance between flexibility, precision, and service. If you've got a design ready to go, or even just sketches and questions about materials and feasibility, the next step is to start a conversation with a specialist who speaks your language.

👉 We hope this helps you! If you're looking for a dedicated service to discuss your specific small batch CNC metal parts needs, our engineering and quoting team is just a click away. Get in touch with our Online Support for a personalized, no-obligation review of your project. Let's turn those designs into reality. 🚀

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque