Hardware shrapnel is often treated with silver plating because it can increase the corrosion resistance of the workpiece, improve reflectivity and conductivity, and make it more aesthetically pleasing. After silver plating, hardware shrapnel will have good conductivity, thermal conductivity, and welding performance.

But in processing engineering, we sometimes find that the surface of the silver plated metal spring fragments has a phenomenon of turning black and yellow. What is the reason for this? How can we solve such phenomena?

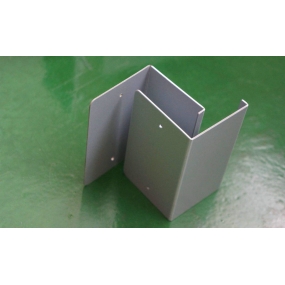

Metal Shrapnel

EMAR Precision is here to tell you that the main reason for the blackening or yellowing of metal spring pieces after silver plating is that the processed metal spring pieces come into direct contact with air, resulting in oxidation. To avoid this situation, we should seal the workpiece and add a desiccant.

When there is inventory of hardware shrapnel, we should package and store it, control the inventory quantity appropriately, and add some desiccants during packaging to avoid such phenomena.

Metal Shrapnel

If there are already oxidized metal fragments, we can use industrial alcohol to erase them or directly re electroplate them in the electroplating factory to solve the problem.

By now, do you all know how to solve and avoid the phenomenon of blackening of hardware shrapnel after silver plating? Follow EMAR Precision Duoduo to push you hardware shrapnel related information.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque