When sourcing precision stainless steel CNC Machining services, selecting the right manufacturing partner is critical for product quality, cost efficiency, and project timelines. As a professional CNC machining service provider, EMAR offers comprehensive solutions for all your stainless steel fabrication needs.

Why Choose Professional Stainless Steel CNC Machining?

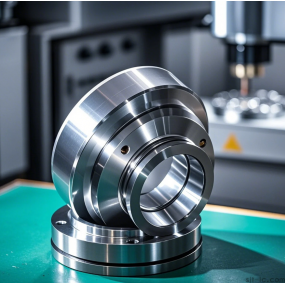

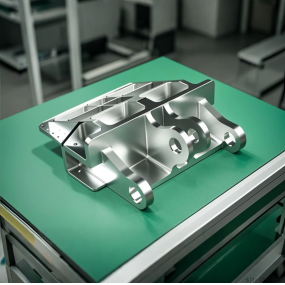

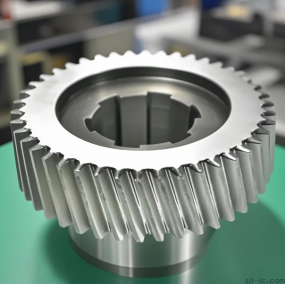

Stainless steel presents unique machining challenges due to its work-hardening properties and high strength. Our CNC machining factory specializes in handling various stainless steel grades (304, 316, 17-4PH, etc.) with precision up to ±.005mm tolerance. We employ advanced CNC milling, turning, and multi-axis machining centers specifically optimized for stainless steel characteristics.

Key Considerations When Selecting a Machining Partner

1. Material Expertise: Verify the factory's experience with your specific stainless steel grade

2. Quality Certifications: Look for ISO 9001, AS910, or industry-specific certifications

3. Equipment Capabilities: Ensure they have modern CNC machines with rigid constructions

4. Surface Treatment Options: Check available finishing processes (passivation, electropolishing, etc.)

5. Prototyping to Production: Confirm seamless scaling from prototypes to mass production

EMAR's Stainless Steel Machining Advantages

As your trusted CNC machining factory recommendation, we offer:

15+ years of stainless steel machining experience

Swiss-type and 5-axis CNC capabilities for complex geometries

Comprehensive quality control with CMM inspection

Competitive pricing with fast turnaround (as quick as 24 hours for prototypes)

One-stop services from design assistance to final assembly

Our technical team can help optimize your stainless steel parts for manufacturability while maintaining functional requirements. Contact EMAR today for a free project evaluation and discover why leading industries trust us for their precision stainless steel components.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque