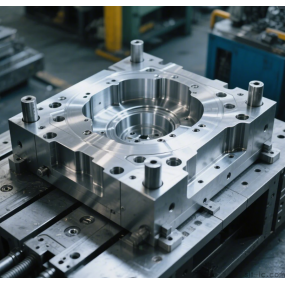

As a leading CNC Machining precision parts manufacturer, EMAR Technology delivers exceptional quality components for industries ranging from aerospace to medical devices. Our ISO-certified facility combines advanced CNC technology with decades of engineering expertise to produce tight-tolerance parts with micron-level accuracy.

Why Choose CNC Machining for Precision Components?

CNC machining precision parts offers unmatched dimensional stability and repeatability compared to conventional manufacturing methods. Our 5-axis CNC mills and Swiss-type lathes can achieve tolerances as tight as ±.005mm, ensuring perfect fit and function for critical applications.

Our Precision Machining Capabilities

EMAR's manufacturing ecosystem includes:

High-speed CNC milling (up to 20,000 RPM)

Multi-axis turning centers with live tooling

EDM wire cutting for complex geometries

CMM inspection with .001mm resolution

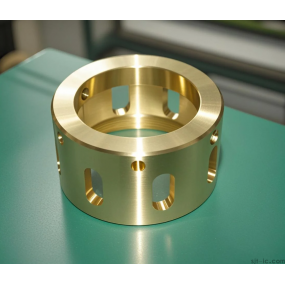

Materials Expertise for Precision Components

We machine over 50+ engineering-grade materials including titanium alloys, stainless steels, and specialty plastics. Our metallurgists select optimal materials based on your application's mechanical, thermal, and corrosion resistance requirements.

Quality Assurance Process

Every CNC machining precision parts undergoes rigorous inspection:

First-article inspection (FAI) with full dimensional report

In-process quality checks using calibrated instruments

Final CMM verification against CAD models

Surface finish analysis with profilometers

Visit EMAR's official website to request a free DFM analysis and quote for your precision machining project. Our engineering team is ready to optimize your designs for manufacturability and cost-efficiency.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque