As a leading CNC lighting parts manufacturer, EMAR specializes in delivering high-precision machined components for decorative, commercial, and industrial lighting applications. Our advanced CNC Machining capabilities enable us to produce intricate designs with tight tolerances, ensuring flawless functionality and aesthetic appeal for your lighting products.

Why Choose CNC Machining for Lighting Components?

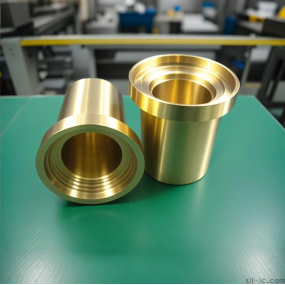

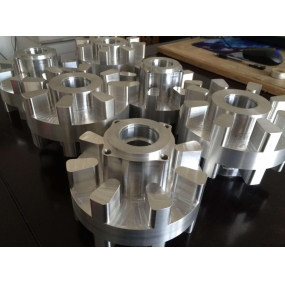

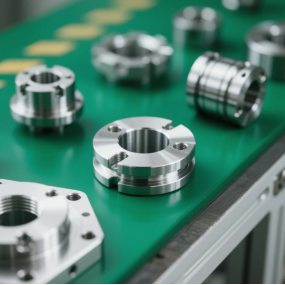

Modern lighting designs increasingly demand complex geometries and premium materials like aluminum, brass, and acrylic. CNC machining offers unmatched precision for creating heat sinks, bezels, housings, and decorative elements with perfect symmetry and smooth finishes. Unlike traditional manufacturing methods, CNC technology guarantees consistency across high-volume production runs while accommodating custom designs.

EMAR's Capabilities as Your Trusted Lighting Parts Supplier

Our CNC machining services cover the entire lighting supply chain:

Material Expertise: Machining aluminum (6061/7075), copper alloys, stainless steel, and engineering plastics

Surface Finishes: Anodizing, polishing, powder coating, and custom textures

Tolerance Control: ±.005mm precision for critical optical and thermal components

Prototyping to Mass Production: Flexible MOQs with rapid 15-day lead times

Applications in Lighting Industry

We manufacture components for:

LED fixture housings and heat dissipation systems

Architectural lighting trim and bezels

Luxury chandelier structural elements

Outdoor lighting corrosion-resistant parts

Partner with EMAR for Your Lighting Projects

With ISO 9001-certified quality systems and dedicated engineering support, EMAR helps lighting designers transform concepts into market-ready products. Our CNC machining solutions combine German DMG Mori equipment with proprietary toolpath optimization to reduce production costs while maintaining premium quality. Contact our technical team at www.sjt-ic.com for DFM analysis and project quoting.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque