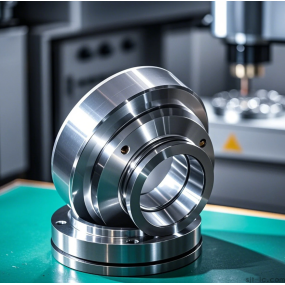

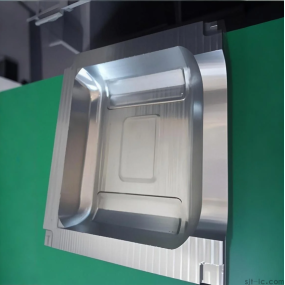

What is CNC Machining of Mechanical Parts?

CNC machining of mechanical parts refers to the precision manufacturing process where computer-controlled machines shape raw materials (such as metal, plastic, or composites) into custom-designed components. This technology ensures high accuracy, repeatability, and efficiency, making it ideal for industries like aerospace, automotive, and medical devices.

Key Advantages of CNC Machining for Mechanical Components

1. Precision Engineering: Tolerances as tight as ±.001mm ensure flawless part functionality.

2. Material Versatility: Compatible with aluminum, stainless steel, titanium, and engineering plastics.

3. Scalability: From prototyping to mass production with consistent quality.

4. Complex Geometries: 5-axis CNC capabilities enable intricate designs impossible with conventional methods.

EMAR's Expertise in CNC Mechanical Part Manufacturing

As a trusted CNC machining service provider, EMAR combines advanced machinery (Mazak, DMG Mori) with ISO 9001-certified processes. Our technical team optimizes every workflow—from CAD/CAM programming to post-processing—to deliver components with superior surface finishes and structural integrity. Visit our website to explore case studies across industries.

Applications of CNC Machined Mechanical Parts

• Automotive: Transmission gears, engine brackets

• Robotics: Actuator housings, joint linkages

• Industrial Equipment: Hydraulic valves, bearing mounts

• Electronics: Heat sinks, enclosures

Why Choose EMAR for Your Project?

1. DFM Analysis: Free design-for-manufacturability feedback to reduce costs.

2. Rapid Turnaround: 15-day standard lead time for most orders.

3. Full-Spectrum Quality Control: CMM inspection and material certifications included.

4. Competitive Pricing: Cost-effective solutions without compromising precision.

Contact EMAR today to discuss your CNC mechanical parts requirements—we transform your blueprints into high-performance components with unmatched reliability.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque