In today's competitive manufacturing landscape, precision CNC Machining stands as the backbone of high-quality component production. At EMAR, we specialize in delivering exceptional CNC machining services that meet the most demanding industry standards.

What Is Precision CNC Machining?

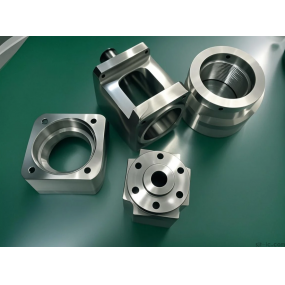

Precision CNC machining refers to the computer-controlled manufacturing process that removes material from a workpiece to create custom-designed parts with extremely tight tolerances. Our advanced CNC machining production capabilities allow us to maintain accuracy within ±.005mm for critical applications.

Why Choose EMAR for Your CNC Machining Needs?

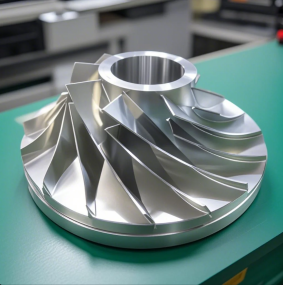

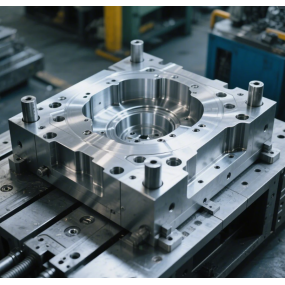

1. Advanced Technology: Our facility houses state-of-the-art 5-axis CNC machines capable of complex geometries

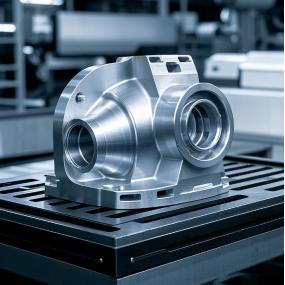

2. Material Expertise: We work with aluminum, stainless steel, titanium, plastics, and exotic alloys

3. Quality Assurance: ISO 9001 certified with comprehensive inspection protocols

4. Rapid Prototyping: From concept to production in record time

5. Custom Solutions: Tailored machining approaches for unique project requirements

Applications of Precision CNC Machining

Our CNC machining services serve diverse industries including:

- Aerospace components

- Medical device manufacturing

- Automotive parts

- Electronics enclosures

- Industrial equipment

Our CNC Machining Production Process

1. Design Analysis: Our engineers review your CAD files for manufacturability

2. Material Selection: Recommending optimal materials for your application

3. Precision Machining: Executing the manufacturing process with meticulous attention to detail

4. Quality Inspection: Verifying dimensions and surface finishes

5. Post-Processing: Applying finishing treatments as required

6. Final Delivery: On-time shipment with complete documentation

For reliable precision CNC machining production that combines technical excellence with competitive pricing, partner with EMAR. Visit our website at https://www.sjt-ic.com/ to request a quote or discuss your project requirements with our technical team.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque