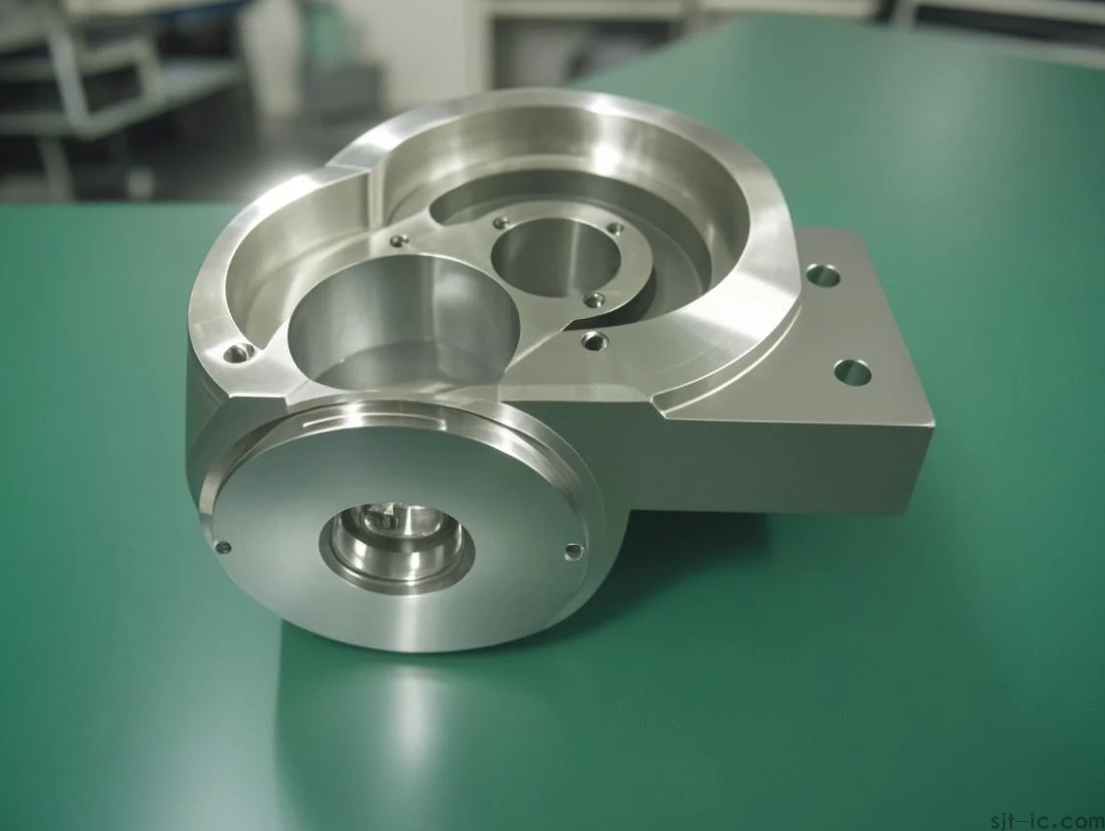

As a leading CNC Machining service provider, EMAR specializes in manufacturing precision custom hardware components for various industries. Our advanced CNC technology ensures exceptional accuracy and consistency for all your hardware part requirements.

Why Choose CNC Machining for Custom Hardware Parts?

CNC machining offers unparalleled precision in producing custom hardware components. Unlike traditional manufacturing methods, our computer-controlled processes guarantee tight tolerances (up to ±.005mm) and perfect repeatability, even for complex geometries. This makes CNC ideal for creating specialized fasteners, brackets, connectors, and other critical hardware components.

Our CNC Hardware Manufacturing Capabilities

EMAR's state-of-the-art CNC machining centers can handle various materials including aluminum, stainless steel, brass, and titanium. We provide comprehensive custom hardware part solutions from prototyping to mass production, with capabilities including:

Precision milling and turning operations

Multi-axis machining for complex parts

Surface finishing options (anodizing, plating, powder coating)

Quality inspection with CMM equipment

Industries We Serve

Our CNC machined hardware components serve diverse sectors including automotive, aerospace, electronics, medical devices, and industrial equipment. Whether you need standard hardware modifications or completely custom-designed parts, our engineering team can deliver optimal solutions.

Quality Assurance Process

Every custom hardware part undergoes rigorous quality checks at multiple production stages. We implement ISO 9001-certified quality management systems and provide full documentation including material certifications and inspection reports.

Get Your Custom Quote Today

Visit our website at https://www.sjt-ic.com/ to submit your hardware part specifications or contact our technical team for expert advice on your CNC machining project.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque