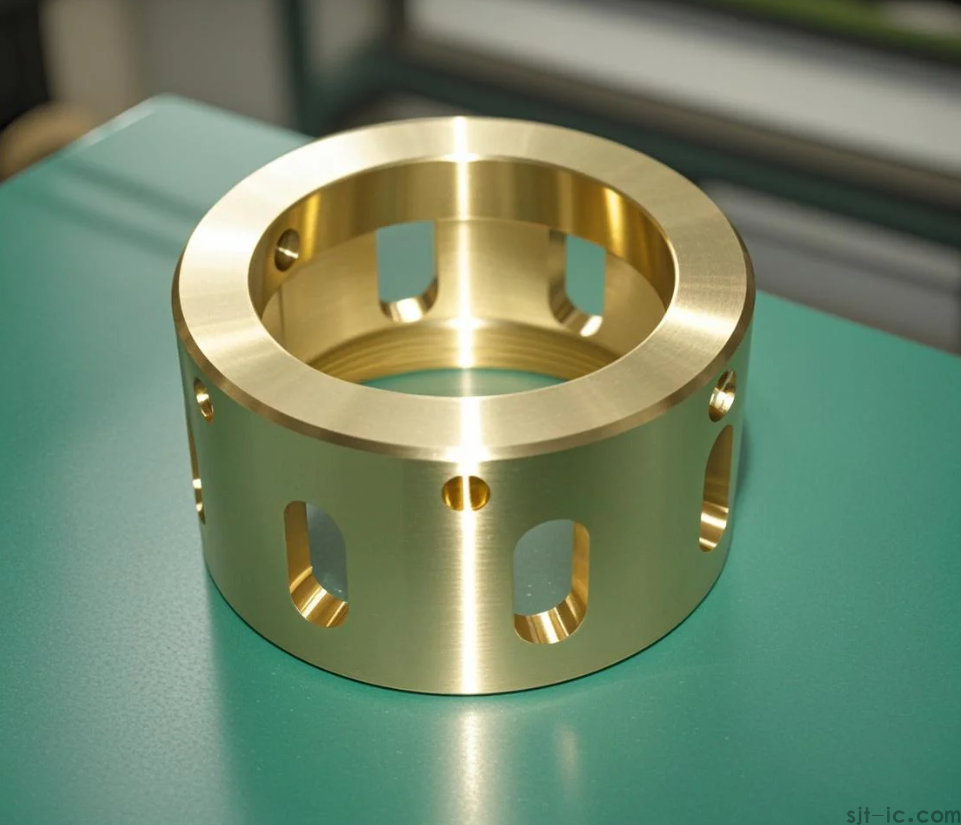

As a leading CNC Machining copper parts specialist, EMAR Company delivers precision-engineered solutions for industries requiring superior electrical/thermal conductivity and corrosion resistance.

Why Choose Copper for CNC Machining?

Copper alloys (C10100-C19700) offer unique advantages in CNC machining applications. Our ISO 9001-certified facility machines copper with ±.005mm tolerances, specializing in:

Electrical busbars and connectors

Heat exchanger components

RFI shielding enclosures

Plumbing fittings

Our Copper CNC Machining Capabilities

EMAR's 5-axis CNC centers execute complex geometries in copper with optimized toolpaths to prevent material galling. We implement:

High-speed machining (up to 12,000 RPM)

Micro-machining (features down to .1mm)

EDM for intricate details

Surface finishes to 8Ra μm

Quality Assurance for Copper Components

Every CNC machined copper product undergoes rigorous inspection including:

3D coordinate measurement (CMM)

Conductivity testing per ASTM B193

Pressure testing for fluid systems

XRF material verification

With 15+ years experience in copper machining, EMAR provides DFM feedback, rapid prototyping (3-5 days), and production runs up to 50,000 units/month. Contact our engineering team for custom copper solutions.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque