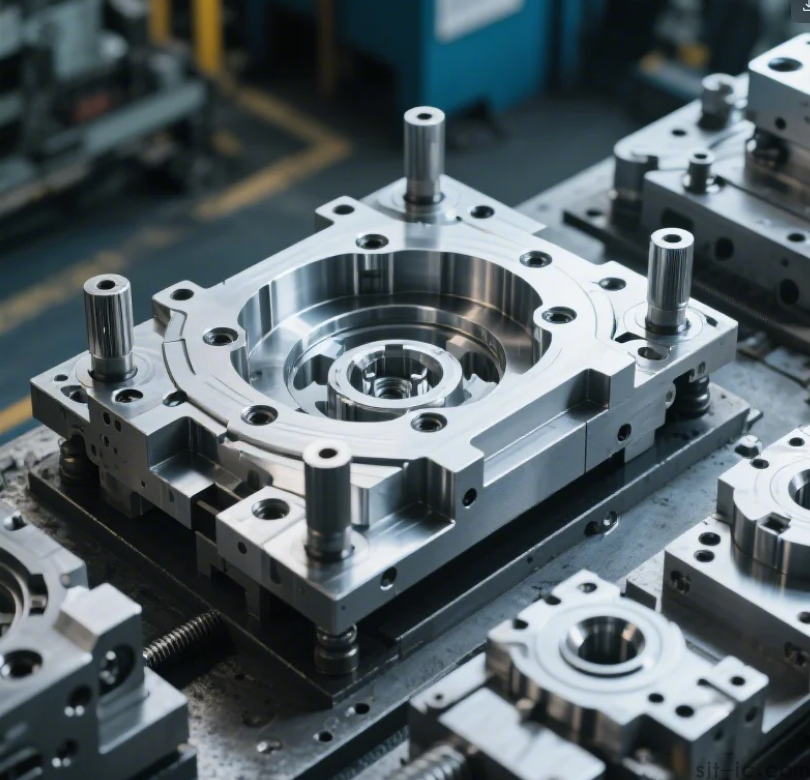

As a professional CNC Machining service provider, EMAR specializes in delivering precision-engineered solutions for industries requiring high-accuracy mold production. This article will walk you through the complete CNC mold machining process, highlighting our technical expertise and quality assurance protocols.

1. Design and CAD Modeling

The process begins with CAD (Computer-Aided Design) modeling, where our engineers convert client specifications into 3D digital blueprints. Using advanced software like SolidWorks or AutoCAD, we optimize designs for manufacturability while ensuring tight tolerances (typically ±.005mm for mold components).

2. Material Selection and Preparation

We use premium-grade tool steels (P20, H13, S7) or aluminum alloys (6061, 7075) based on application requirements. Raw materials undergo ultrasonic testing to verify internal integrity before machining begins.

3. CNC Programming

Our CAM programmers generate toolpaths using Mastercam or PowerMill, selecting optimal:

Cutting tools (carbide end mills, ball nose cutters)

Spindle speeds (15,000-30,000 RPM for high-speed machining)

Feed rates (optimized for material and surface finish requirements)

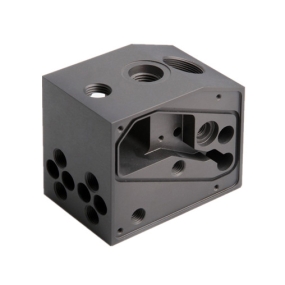

4. Precision Machining Operations

The CNC mold machining involves sequential processes:

Roughing: Removes 80-90% material using high-efficiency milling strategies

Semi-finishing: Achieves near-net shape with .1-.2mm allowance

Finishing: Delivers Ra .4μm or better surface finish

EDM (if required): For complex geometries or hardened steels

5. Quality Control and Inspection

Every mold undergoes rigorous inspection using:

CMM (Coordinate Measuring Machine) for dimensional verification

Surface profilometers for finish analysis

Optical comparators for profile checking

Why Choose EMAR for Your CNC Mold Machining?

With 15+ years of experience in CNC machining services, EMAR offers:

50+ advanced CNC machines (5-axis, Swiss-type, and turning centers)

ISO 9001:2015 certified quality management

Fast turnaround (prototypes in 5-7 days, production in 2-3 weeks)

Comprehensive post-processing (heat treatment, polishing, coating)

Contact our technical team at www.sjt-ic.com to discuss your specific mold requirements and receive a DFM (Design for Manufacturing) analysis.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque