Understanding CNC Machining for Stainless Steel Hardware

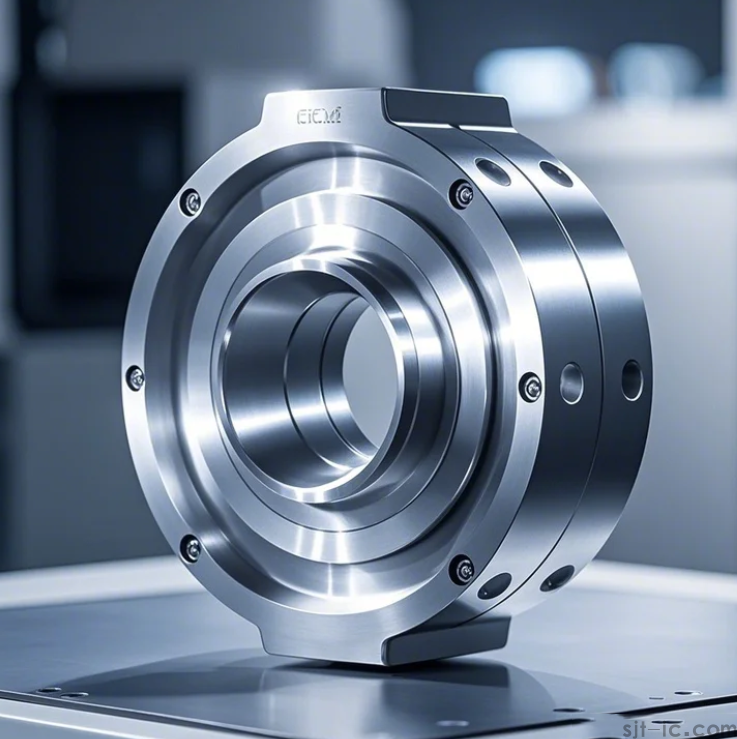

CNC machining of stainless steel hardware parts is a precision manufacturing process that leverages computer-controlled tools to shape and finish durable metal components. Stainless steel, known for its corrosion resistance and strength, is widely used in industries like automotive, aerospace, and medical devices. At EMAR, we specialize in delivering high-tolerance, complex geometries with superior surface finishes to meet stringent industry standards.

Key Advantages of Choosing CNC for Stainless Steel

1. Precision & Consistency: CNC technology ensures micron-level accuracy, critical for stainless steel hardware parts requiring tight tolerances.

2. Material Versatility: Our machines handle grades like 304, 316, and 17-4PH, optimizing for hardness or corrosion resistance.

3. Cost-Efficiency: Automated processes reduce waste and labor costs for bulk orders.

EMAR’s Capabilities in Stainless Steel CNC Machining

With advanced multi-axis CNC hardware machining centers, EMAR offers:

- Complex Part Production: Threaded fasteners, valve components, and custom fittings.

- Secondary Services: Deburring, polishing, and passivation to enhance durability.

- Quality Assurance: ISO-certified inspections with CMM and surface roughness testers.

Why Partner with EMAR?

As a trusted CNC machining supplier, we combine cutting-edge technology with 10+ years of expertise. Our client-centric approach includes DFM feedback, rapid prototyping, and on-time delivery—ensuring your stainless steel parts meet exact specifications. Visit EMAR’s official website to explore our portfolio or request a quote today.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque