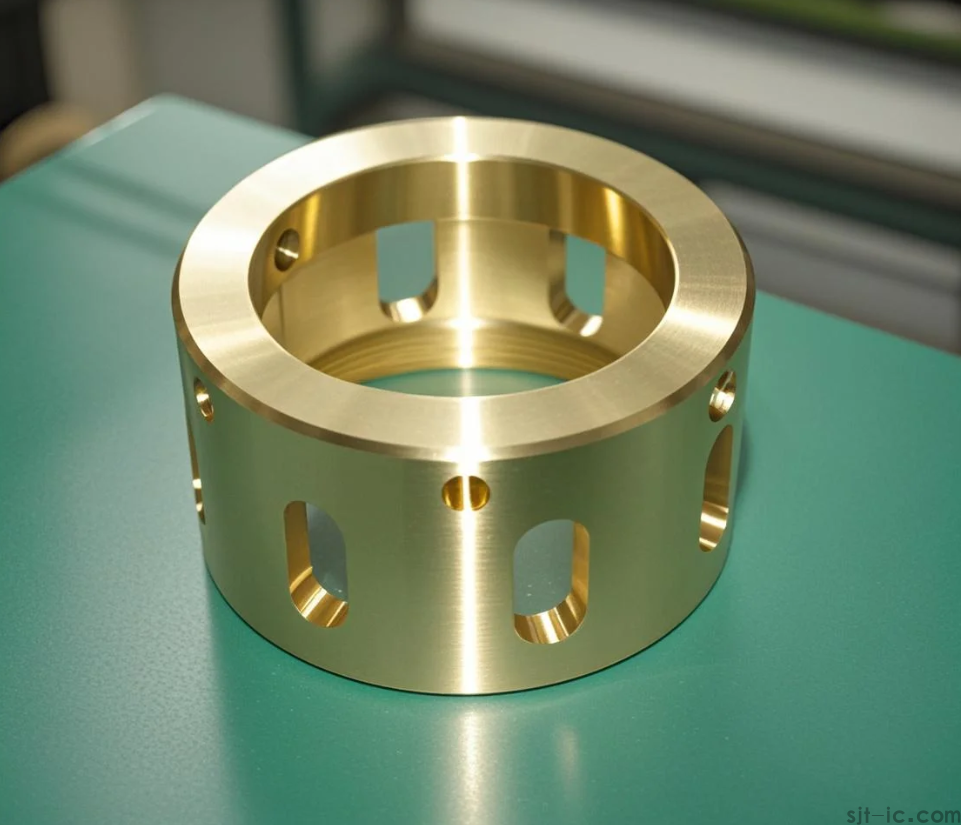

Understanding CNC Copper Machining

CNC copper machining is a specialized manufacturing process that utilizes computer numerical control (CNC) technology to shape copper materials into precise components. As a highly conductive and malleable metal, copper presents unique challenges and opportunities in machining applications.

Key Steps in the CNC Copper Machining Process

The complete CNC copper machining process flow involves several critical stages:

Material Selection: Choosing the appropriate copper alloy (C101, C110, etc.) based on application requirements

CAD Design: Creating detailed 3D models of the desired component

CAM Programming: Converting designs into machine-readable instructions

Machine Setup: Installing proper tooling and fixtures for copper machining

Precision Machining: Executing milling, turning, or drilling operations

Quality Inspection: Verifying dimensional accuracy and surface finish

Post-Processing: Applying necessary treatments (polishing, plating, etc.)

Technical Considerations for Optimal Results

To achieve superior results in CNC copper machining, several technical factors must be addressed:

Tool Selection: Carbide tools with specialized coatings perform best with copper

Cutting Parameters: Optimal spindle speeds and feed rates prevent material galling

Coolant Strategy: Proper cooling prevents heat buildup and maintains dimensional stability

Chip Control: Effective chip evacuation prevents re-cutting and surface defects

EMAR's Expertise in CNC Copper Machining

At EMAR, we've perfected our CNC copper machining capabilities through years of experience. Our facility features:

High-precision 5-axis CNC machines specifically configured for copper

Advanced metrology equipment for micron-level quality control

Custom tooling solutions for complex copper components

Strict process documentation and quality assurance protocols

Applications of CNC Machined Copper Parts

Our CNC copper machining services support various industries including:

Electrical and electronics (busbars, connectors, heat sinks)

Automotive (welding nozzles, electrical components)

Medical (surgical instruments, imaging components)

Renewable energy (solar panel components, wind turbine parts)

For your next copper machining project, trust EMAR's technical expertise and commitment to quality. Contact our engineering team today to discuss your specific requirements and receive a competitive quote.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque