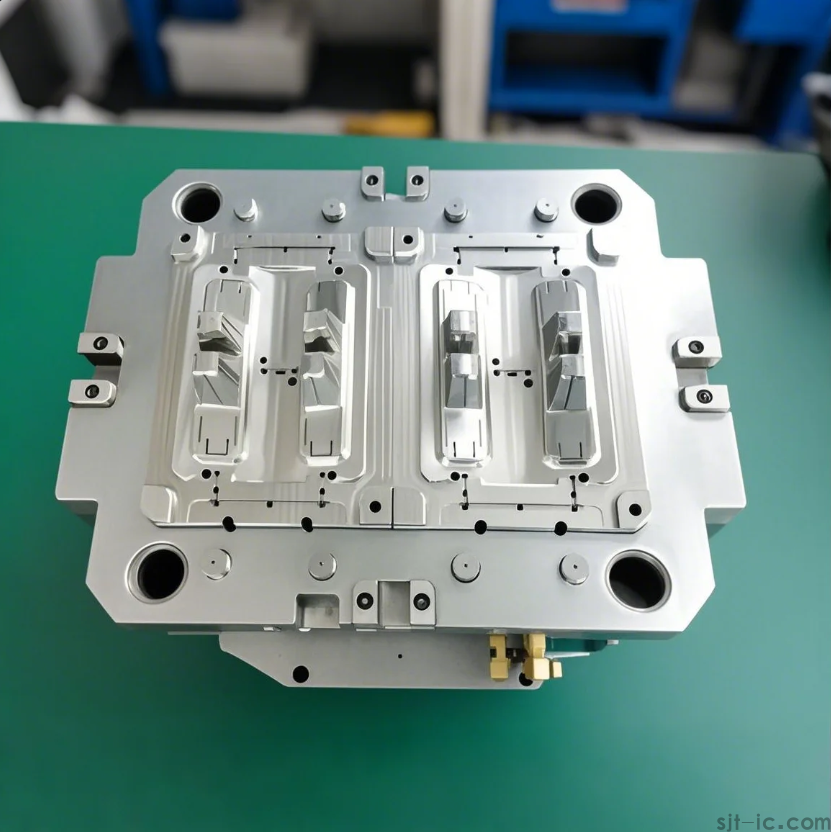

As a leading CNC Machining service provider, EMAR specializes in delivering high-precision mold manufacturing solutions for industries requiring micron-level accuracy. Our CNC mold precision machining process combines advanced technology with rigorous quality control to meet the most demanding specifications.

Understanding CNC Mold Machining

Precision mold manufacturing requires specialized CNC machining techniques to create complex geometries with tight tolerances. Our process begins with CAD/CAM programming that optimizes tool paths for mold cavities, cores, and inserts.

Key Stages of Our Precision Process

1. Material Selection: Using premium tool steels, aluminum alloys, or copper alloys based on application requirements

2. 5-Axis Machining: For complex contours and undercuts in mold components

3. EDM Machining: For intricate details and hardened materials

4. Surface Finishing: Including polishing, texturing, and coating applications

Quality Assurance Protocols

Every mold undergoes comprehensive inspection using CMM (Coordinate Measuring Machines) and optical comparators to ensure dimensional accuracy within ±.005mm. Our ISO 9001-certified process guarantees repeatable quality for high-volume production.

Why Choose EMAR for Mold Machining?

- 15+ years of specialized experience in precision mold manufacturing

- Advanced CNC equipment from DMG Mori and Makino

- DFM (Design for Manufacturing) support included

- Fast turnaround with 24/7 production capabilities

Discover how our CNC mold precision machining process can optimize your tooling production. Contact EMAR for a free project evaluation today.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque