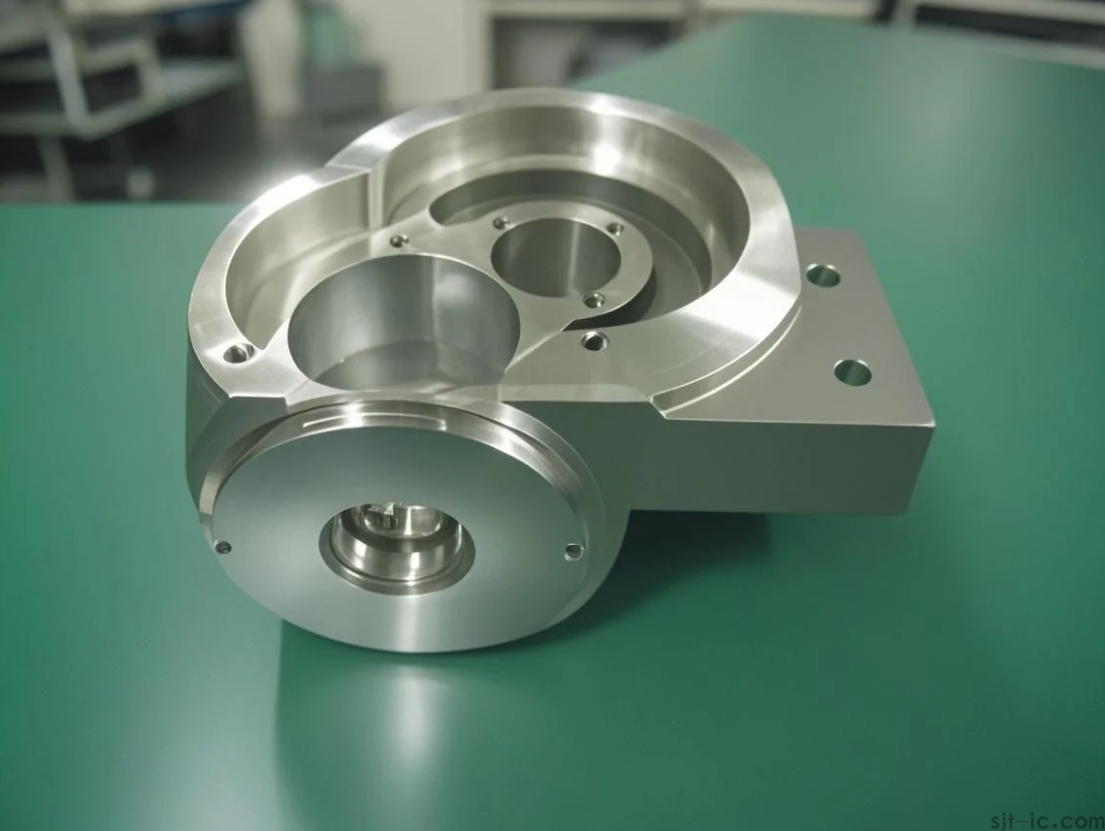

As a leading CNC Machining manufacturer, EMAR specializes in delivering high-precision components for industries ranging from aerospace to medical devices. Our expertise in precision CNC machining ensures tight tolerances (±.001mm) and superior surface finishes for your most demanding projects.

What Is Precision CNC Machining?

Precision CNC machining refers to the subtractive manufacturing process that uses computer-controlled machines to remove material from a workpiece with exceptional accuracy. Unlike conventional machining, our 5-axis CNC machines can produce complex geometries in a single setup, reducing errors and improving efficiency.

Key Advantages of Our Precision CNC Services

1. Material Versatility: We machine over 50+ materials including aluminum alloys, titanium, and engineering plastics

2. Advanced Quality Control: Equipped with CMM and optical comparators for 100% inspection

3. Rapid Prototyping: 3-5 day turnaround for prototype orders

4. Cost Optimization: DFM analysis to reduce your part cost by up to 30%

Our Precision Machining Capabilities

• Tolerance: From ±.005mm to ±.001mm for critical dimensions

• Surface Finish: Ra .2μm to 3.2μm achievable

• Maximum Part Size: 800×500×300mm (3-axis), 400×300×300mm (5-axis)

• Secondary Services: Anodizing, plating, heat treatment, and assembly

Industry Applications

Our precision machined components serve critical functions in:

- Medical: Surgical instruments, implantable devices (ISO 13485 certified)

- Aerospace: Aircraft structural components (AS910 compliant)

- Automotive: Engine parts, transmission components

- Electronics: Heat sinks, enclosures with EMI shielding

Why Choose EMAR for Your CNC Machining Needs?

With 15+ years of experience and 20+ CNC machines in our Shenzhen facility, we combine German-engineered equipment with skilled machinists to deliver:

1. On-Time Delivery: 98% on-time rate with real-time production tracking

2. Technical Support: Dedicated engineers for process optimization

3. Competitive Pricing: Chinese manufacturing costs with European quality standards

4. IP Protection: Strict NDA procedures and secure data handling

Request a free project review today at www.sjt-ic.com or email our technical team with your CAD files for immediate DFM feedback and quotation.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque