Hey, are you new to aluminum CNC Machining and find the whole set of processes extremely complicated, not knowing where to start? Don’t worry—today I’ll break it down for you in plain language, and I guarantee you’ll understand 70% to 80% of it after reading! 😎

Aluminum Profile CNC Cutting Step

Cutting is the first step in CNC machining; simply put, it’s cutting aluminum materials into the desired length according to requirements. 📏 But did you know? Cutting isn’t just a random process—it must be done in accordance with the design drawings. If high precision is required, the accuracy even needs to be controlled within 0.1mm! The commonly used cutting methods are laser cutting and mechanical cutting. Laser cutting is more precise but also more costly. Here’s my suggestion: always calibrate the equipment before cutting. Otherwise, if the dimensions are off, all subsequent work will be in vain!

Aluminum CNC Drilling Process

Drilling is a technical task—aluminum profile connections rely entirely on it! 🔩 Through holes and stepped holes are the most common types: through holes are used for ordinary bolt connections, while stepped holes are suitable for hidden connectors. Here’s a little tip: when drilling, you must control the rotational speed and feed rate. Too high a rotational speed can easily damage the tool, while too low a speed affects efficiency. The parameters I often use are a rotational speed of 2000-3000 rpm and a feed rate of 0.1 mm/rev—you can give them a try!

Aluminum Profile Tapping Tips

Tapping refers to creating threads inside holes to facilitate screwing in screws later. 🔧 However, aluminum is relatively soft, so tapping can easily cause thread damage or tool breakage—so you need to be extra careful! Never skimp on cutting fluid; it can lower the temperature and reduce friction. Additionally, tapping should be done in two steps: rough tapping (to create the initial thread path) and finish tapping (to refine the details). This way, the threads will be smoother and more durable. Honestly, this work requires patience—you can’t rush it!

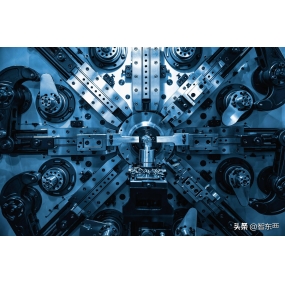

Key Points of CNC Milling for Aluminum

Milling is used to machine complex shapes, such as grooves or curved surfaces. 🔄 What’s the biggest concern with aluminum milling? Thermal deformation and vibration! Therefore, the fixture must be stable, and you should choose sharp cemented carbide tools with reasonable cutting parameters—you can use a high feed rate for rough machining, but for finish machining, you need to take it slow to ensure quality. A reminder from me: always measure the dimensions after milling. Don’t wait until assembly to find out there’s a problem—it’ll be too late!

Aluminum CNC Surface Treatment

The surface of machined parts often has tool marks or burrs and needs to be treated before use. ✨ Sandblasting and anodizing are the most common methods: sandblasting creates a uniformly rough surface, while anodizing enhances wear resistance and corrosion resistance. Surface treatment isn’t just for aesthetics—it’s more about improving performance. For example, aluminum parts after anodizing can have their service life extended several times!

Okay, that’s basically a full coverage of the aluminum CNC machining processes. My personal experience in this field is that “details determine success or failure”—choosing the right tool, adjusting parameters accurately, and conducting strict quality inspections are all indispensable. I hope this article helps you. If you have any questions, feel free to leave a comment and discuss!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque