🤔 Which CNC Machining customization provider is reliable? How to choose small - scale CNC machining customization services?

I often receive questions from fans: "I want to find CNC machining customization services, but I'm afraid of being cheated. What should I do?" Don't panic! Today, I will take you to explore the inside story, hoping to help you~

🔍 1. Why Is the Demand for "Small - Scale Customization" Becoming More and More Common?

Nowadays, many entrepreneurial teams or small hardware factories often need dozens of precision parts - but large factories simply ignore such small orders! 😥 At this time, small - scale CNC machining services become a lifesaver. Their characteristics are very straightforward:

- Flexible minimum order quantity: They can accept orders for even 1 piece, which is suitable for prototype trial production;

- High communication efficiency: Designers directly communicate with technicians, reducing misunderstandings of drawings;

- Controllable cost: It eliminates mold fees, and materials are cut on demand without waste.

But a problem also arises: the quality of small - batch manufacturers varies greatly. How to choose? Keep reading!

💡 2. Three Hidden Indicators of Reliable Manufacturers

Many people only compare prices and construction periods, but ignore these points:

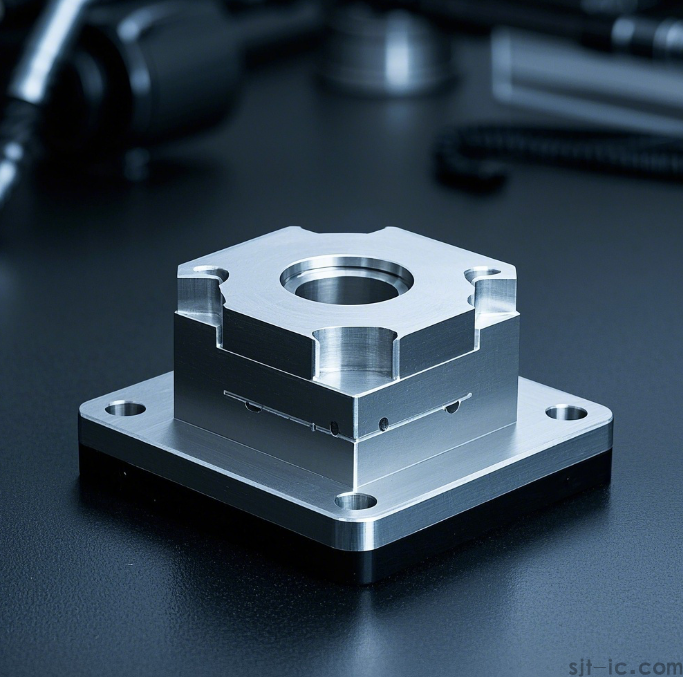

1. Tool compensation accuracy: CNC controls tools through computer programming, and the fine adjustment of compensation values directly affects whether the hole positions are aligned. I have seen some factories set the parameters incorrectly by 0.1mm, which caused the assembly of the entire batch of parts to fail!

2. Material traceability capability: Do they provide material certification? The performance of 6061 aluminum and 7075 aluminum differs by 2 times, and it will be a disaster if they are mixed up;

3. Trial cutting process: Regular manufacturers will first produce 1 piece for quality inspection - send you a measurement report, and only start mass production after confirmation.

📊 3. Comparison Between Small - Scale and Large - Scale Services (Quick Overview in Table)

| Evaluation Dimension | Small - Scale CNC Customization | Large - Scale CNC Mass Production |

| ---- | ---- | ---- |

| Minimum Order Quantity | 1 - 50 pieces | 1000 + pieces |

| Communication Response Speed | Usually within 24 hours | May take 3 - 5 days |

| Suitable Scenarios | Prototype sampling, personalized modification | Auto parts, mass production of navigation marks |

| Unit Cost | Relatively high | Lower after cost amortization |

👉 Conclusion: If you are engaged in the iteration of innovative products, choosing small - scale services is more agile!

❓ 4. Q & A: How to Judge "Which One Is Reliable"?

Q: How to verify the strength of a manufacturer without prior cooperation?

A: Let me teach you two free methods -

- Ask the manufacturer to send videos of previous cases: Check the age of the machine tools and the cleanliness of the workshop;

- Request a free trial production of simple parts: For example, an aluminum buckle, to test the dimensional error and surface finish.

Q: What hidden tricks are there in the quotation?

A: Be careful of these "additional costs":

- Programming fee (whether it is calculated separately by the hour);

- Tool wear allocation fee;

- Surcharge for post - heat treatment.

✅ The regular practice is: The package price includes all processes, and it should be clearly stated in the contract!

💎 Personal Opinion: For Small - Batch Orders, More Attention Should Be Paid to "Collaborative Flexibility"

In my opinion, the competition in the CNC industry is fierce now, and the gap in equipment is actually not large - the real gap lies in the details of services. For example:

- Can they accept urgent drawing revisions in the middle of the night?

- Do they take the initiative to propose structural optimization to help you save materials?

- Is a 3D scan image attached to the quality inspection report?

These soft strengths are the key to breaking through in the niche market!

🚀 5. Future Trend: Digitalization Is Lowering the Threshold for Customization

Now, many manufacturers have launched real - time construction period tracking systems, allowing you to check the production progress on your mobile phone; some even use AI to predict tool wear and remind you to replace tools in advance to avoid waste products.

What does this mean? ➡️ The cost of small - batch production will become lower and lower, and personalized manufacturing will no longer be a game for giants!

Therefore, novices should not be afraid of difficulties. Find manufacturers that focus on small and micro customers, use the methods in this article to screen, and start with low - cost trial orders~ I once helped a friend select a high - quality factory using this method. The first order was 10 titanium alloy parts, and the precision reached 0.02mm! ✨

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque