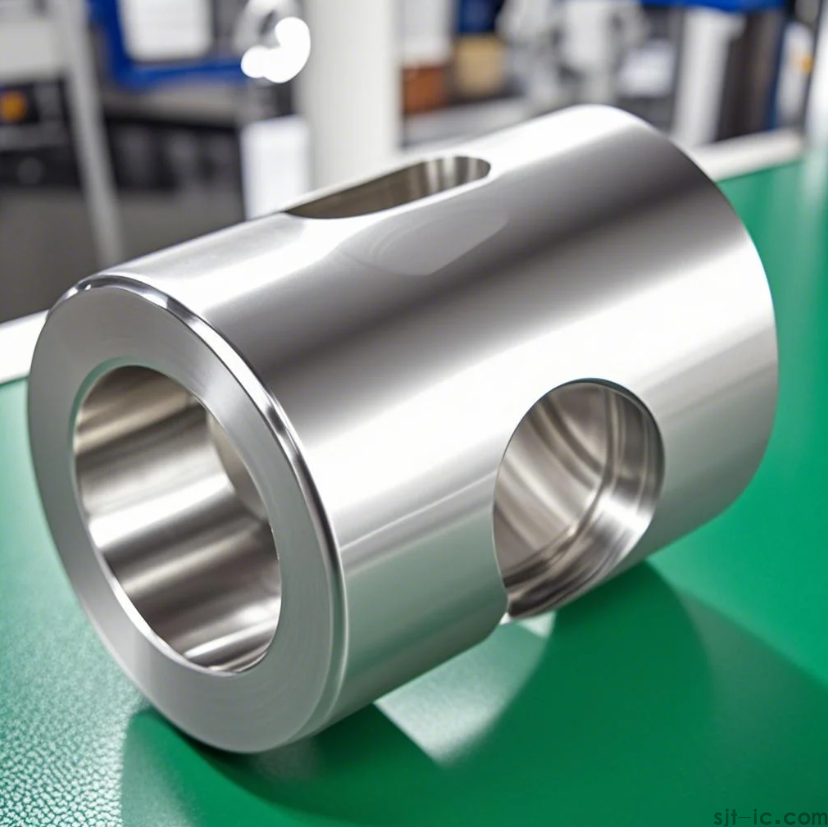

Oh, recently many fans have sent me private messages: they want to find manufacturers for precision CNC Machining wholesale, but with so many suppliers on the market, which one is really reliable for batch CNC aluminum alloy machining? Don't worry, today we'll break this down thoroughly and make it clear!

👉 First, a reality check: not all manufacturers that claim to offer "batch wholesale" can handle your orders! Some small workshops have outdated equipment, and their precision can't even stay stable within ±0.1mm. By the time you face mass product scrapping, it'll be too late to cry... So, these points are crucial to check:

- Is the equipment list transparent? How many 5-axis machines and turn-mill centers do they have? Is the proportion of old machine tools high?

- Is the quality control process solid? Do they have coordinate measuring machines? Do they conduct 100% inspection or just sampling inspection?

- Is the material source reliable? Is the aluminum alloy of national standard grade? Will they pass off inferior mixed materials as qualified ones?

I've visited several factories in person and noticed a phenomenon: manufacturers that can truly handle batch aluminum alloy machining dare not boast about "low prices" recklessly — because the costs of tool wear and quality inspection alone are fixed! So if you encounter an unusually low quotation, it's better to reject it directly 😅.

🔍 Solutions to Difficulties in Batch Machining

Many people think "batch processing is all about competing on price", but in fact, stability is the key! For example, when machining aluminum alloy parts, it's easy to encounter the following problems:

- Deformation issue: Thin-walled parts deform due to heat during machining, and the dimensions deviate so much that they're unrecognizable...

- Surface scratches: Unreasonable fixture design or rough storage during logistics leave scratches all over the parts when received.

- Batch differences: Even within the same batch of orders, there are color differences in the anodized finish?!

How do reliable manufacturers address these issues?

- They use hydraulic fixtures to reduce clamping stress and adopt segmental cutting with 5-axis machines to control temperature.

- They customize blister trays separately, with independent slots for each part to avoid collision during transportation.

- They regularly test the concentration of the anodizing bath solution and even make test samples for each batch to compare color codes.

📊 How Can Newbies Screen Manufacturers Quickly?

Here are some practical judgment methods (with real comparisons):

| Inspection Item | Practices of High-Quality Manufacturers 💪 | Practices of Problematic Manufacturers 💣 |

|-----------------------|---------------------------------------------------------------------|---------------------------------------------------------------------|

| Quotation Response | List details of working hours, consumables, and taxes clearly | Only provide a total price; when pressed, they just say "this is industry practice" |

| Sample Stage | First make samples for filing and record the entire process via video | Polish samples meticulously but produce bulk goods casually |

| After-Sales Commitment| Sign a quality agreement, promising replacement/refund for defective products and supplementary production | Only say "don't worry" verbally; when problems occur, they argue over freight costs |

💡 My Suggestion: Place a trial order of 300-500 pieces first! Don't think it's too few — this quantity is enough to assess process stability, on-time delivery rate, and after-sales response speed.

💬 Personal Insights

Having been in this industry for ten years, I've noticed a rule: manufacturers that dare to take urgent orders aren't necessarily good, but those that dare to take "revision orders" are definitely reliable! For example, once a customer missed marking tolerances on the drawing, and the manufacturer took the initiative to feedback and suggested using the ISO2768-m medium grade, avoiding mass deviation. This kind of technical experience and sense of responsibility is far more important than saving a few cents!

Finally, a reminder: Don't just fixate on the unit price when it comes to batch aluminum alloy machining! You need to calculate the cost by weighting the three dimensions of precision, delivery, and after-sales service to find a truly worry-free partner. Next time you encounter someone promoting "100,000 pieces delivered in three days", remember to ask one more question: "Are your machine tools rented or owned?" 🤫

Would you like me to organize a bilingual checklist for auditing batch CNC aluminum alloy machining manufacturers? It will include key inspection items in both Chinese and English, as well as judgment standards and risk prompts, helping you efficiently verify the strength of manufacturers during factory visits.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque