🤔 Why do you keep worrying about "what can CNC machine"?

Actually, CNC can machine almost anything! From phone cases to rocket components, but the biggest confusion for beginners is — "Is my product suitable for CNC Machining?" 😵

Let’s categorize it simply:

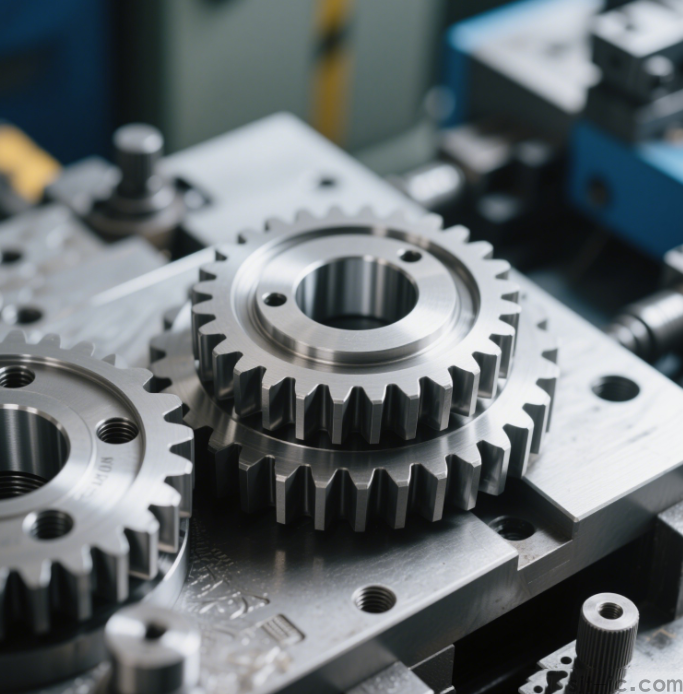

- Metal materials: Aluminum, steel, copper, and even titanium alloy! Examples include medical device parts and automotive gears.

- Plastic materials: ABS, PC, and nylon. They’re perfect for prototyping or small-batch production.

- Complex shapes: Impellers and irregular curved surfaces can be directly machined by 5-axis machines.

But ❗ Not all materials work — materials like rubber are too soft, and ceramics are too brittle; CNC machining will easily damage them!

🔍 Pitfalls in non-standard customization: 90% of beginners fall here!

Non-standard parts equal one-of-a-kind designs, but there are many pitfalls during customization:

1. Unclear drawings: Tolerances and material requirements are vague, so manufacturers will just "play it by ear"…

2. Wrong material selection: For example, medical parts need corrosion resistance, but if you choose ordinary aluminum, all parts will be scrapped after oxidation!

3. Ignoring costs: Using 5-axis machining for small-batch production will make the unit price skyrocket 💸

👉 Comparison table to avoid pitfalls:

| Requirements | Recommended Process | Cost Reference |

| ---- | ---- | ---- |

| Small-batch complex parts | 4-axis / 5-axis CNC | Medium-high |

| Simple metal parts | 3-axis CNC | Low |

| Plastic prototypes | 3-axis CNC + manual polishing | Low |

💡 Editor’s bold view: Don’t fixate on precision for non-standard customization!

Many people insist on tightening tolerances to ±0.01mm, but most products don’t need that at all! For parts like casings and brackets, ±0.1mm is more than enough — and this can cut costs by half ✅

What you really need to focus on:

- Surface treatment: Processes like anodizing and sandblasting. Corrosion resistance is more important than precision.

- Lead time negotiation: Is a 30% premium required for rush orders? It’s better to compare multiple suppliers.

- Inspection reports: Reputable manufacturers must provide quality inspection certificates. Don’t trust "visual inspection"!

🚀 Ultimate advice for beginners

1. Start with small batches: First produce 50 trial units, don’t place orders for 10,000+ units right away.

2. Stick to 6061 aluminum: It has low cost, is easy to machine, and is suitable for most products.

3. Learn "pseudo-non-standard": Fine-tune the design based on standard processes to reduce costs by 60% directly!

💥 Finally, a key statistic: For non-standard parts, the cost saved by structural optimization is 30% more than cutting machining fees. So, paying more attention to details during the design stage is more profitable than pressing for lower machining unit prices later!

Do you want me to sort out a CNC Machining Material Selection and Cost Control Guide? It will help you make clearer decisions when dealing with CNC machining-related matters later.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque