〖Medical Device CNC Machining Wholesale〗

To be honest, the requirements for parts in the medical industry are extremely strict! The precision must be controlled within ±0.005mm, and the surface must be smooth without burrs—otherwise, how could they be used on the human body? For components like surgical instruments and implants, 5-axis CNC machining is a must. When choosing a manufacturer, qualifications matter: ISO 9001 certification and medical industry certifications are the minimum standards. Don’t be tempted to choose small workshops for lower prices—after all, human lives are at stake!

〖Custom Stainless Steel Hardware Fittings Machining〗

Custom (non-standard) hardware fittings are essentially "made-to-order products." Examples include special-shaped connectors and custom screws, which are often produced in small batches but require complex processes. Machining stainless steel is challenging due to its high hardness, which easily wears out cutting tools. Therefore, high-speed CNC machines paired with specialized coated tools are necessary. Here’s a frank tip: Some manufacturers offer low quotes but secretly use second-hand tools, resulting in burrs on the finished parts—you must keep your eyes open!

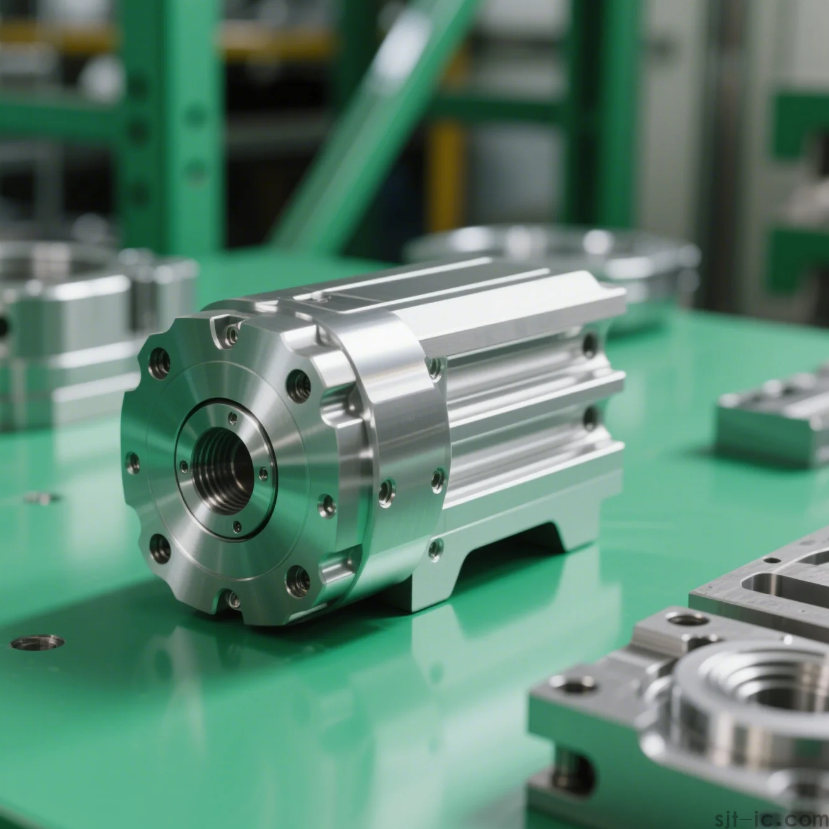

〖5-Axis CNC Precision Part Machining〗

5-axis CNC machining is truly impressive! It can machine five surfaces in a single setup, easily achieving a precision of ±0.01mm. It is indispensable for aerospace components and high-end automotive parts. However, the equipment is expensive—an imported 5-axis machine can cost over one million yuan—so most small manufacturers cannot afford to operate it. When selecting a manufacturer, it’s advisable to ask directly: "What brand of 5-axis machine do you use? DMG MORI or Mazak?" If they can’t answer this question, you can basically rule them out.

〖Swiss-Type Lathe Machining of Stainless Steel Precision Parts〗

Swiss-type lathes are particularly suitable for machining long, thin shaft parts, such as watch screws and micro-axis cores. Their tools move synchronously with the material, ensuring more stable cutting. For stainless steel parts? Simply add cutting fluid to prevent thermal deformation. However, here’s a reminder: Programming for Swiss-type lathes is complex, and inexperienced operators are likely to produce defective products—when choosing a manufacturer, always check their case photos first!

〖Turn-Mill Compound Machining of Aluminum Alloy Parts〗

Aluminum alloy is lightweight and soft, making it ideal for turn-mill compound machines, which can perform turning and milling (e.g., slotting) simultaneously—offering extremely high efficiency. For products like drone casings and radiator fins, this method can significantly reduce costs during mass production. But note this: Aluminum parts are prone to oxidation, so anodizing treatment is essential. Without it, the surface will become uneven over time, which is not only unsightly but also affects performance.

Personal Insights:

When choosing a CNC manufacturer, don’t just compare prices! Check their equipment list, quality inspection reports (do they have a coordinate measuring machine?), and even the cleanliness of their workshop—if a factory is covered in oil stains, its quality control is likely poor. By the way, the industrial chains in Dongguan and Shenzhen are the most mature, but they are also filled with small manufacturers. It’s recommended to prioritize established ones (e.g., those founded over 10 years ago)—at the very least, the risk of them closing down suddenly is much lower!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque