Feeling overwhelmed trying to find a CNC shop you can actually trust? You're not alone. 🤯 Every day, engineers and purchasing managers just like you need parts made, but the fear of late deliveries, shocking extra costs, or just plain bad quality is all too real. It's not just about finding a supplier; it's about finding the right partner. So, how do you separate the best from the rest? Let's break it down, step by step.

What's the First Step in Vetting a CNC Machining Partner?

Before you even think about asking for a quote, you need to do some detective work. The goal here is to quickly filter out the less serious options. A company's online presence, while not the whole story, can be a huge red flag—or a green light.

Look for these clues on their website:

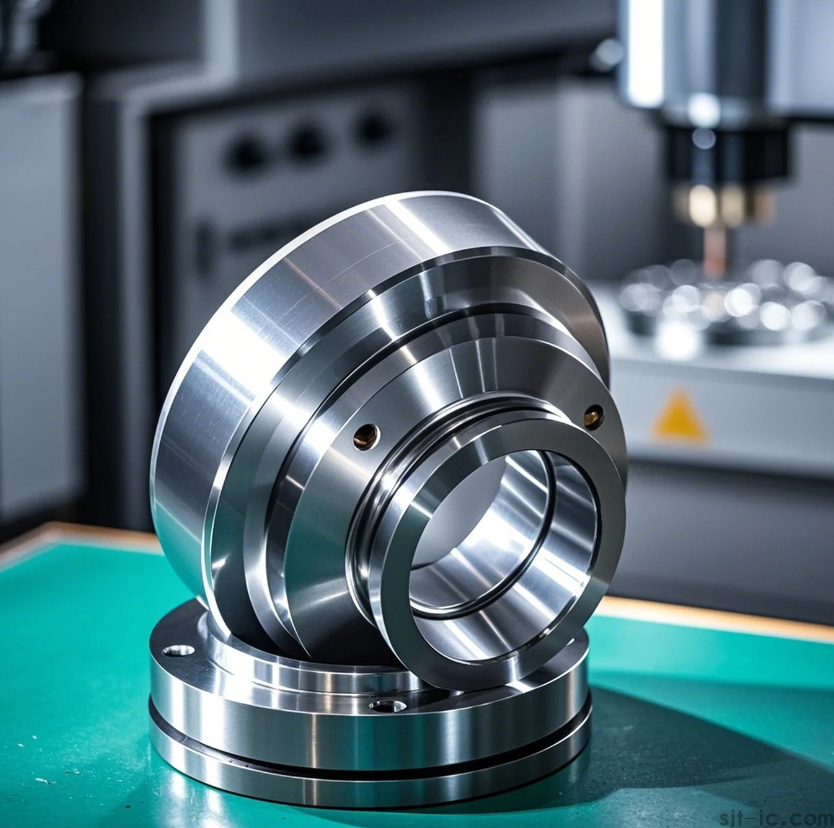

- 🛠️ A clear gallery of their past work. Do the parts look like something you'd need? This gives you a feel for their experience.

- 📄 Information about their machines and measuring tools. Modern equipment often suggests better consistency and capability.

- 🧾 Detailed service pages. Do they explain their process for handling quotes, quality control, and delivery?

If a website looks like it was made in the 199s and has barely any useful information, that might be a sign they're not keeping up with the times in other areas, too. However, it's worth remembering that some fantastic, highly specialized shops are just terrible at marketing. So, use the website as a first filter, not the final judgment.

Why is Communication the Make-or-Break Factor?

You can have the best equipment in the world, but if you can't communicate effectively with your supplier, the project is likely to fail. Pay very close attention to how they respond to your initial inquiry.

A responsive partner will:

- 💬 Ask clarifying questions about your drawing or 3D model. This shows they're actually thinking about your project.

- ⏱️ Provide a realistic timeline for the quote and for production.

- 🧐 Point out potential issues with your design for manufacturability (DFM). This is pure gold—it saves you time and money.

On the flip side, if you get a generic, one-line quote back with no questions asked, be wary. It might suggest they either didn't look at your files properly or they plan to hit you with change orders later.

How Can You Really Gauge Their Commitment to Quality?

Anyone can say "we care about quality." The proof is in their process. You need to dig a little deeper here. Don't be shy about asking direct questions; a professional shop will welcome them.

Key questions to ask:

- "What is your first-article inspection process?"

- "Do you provide inspection reports with the delivered parts?"

- "How do you handle a situation if a part doesn't meet the specification?"

Their answers will tell you everything. A shop that has a clear, documented process for checking parts is a shop that sleeps well at night because they know their work is good. This focus on getting the machining precision right from the start is what separates the ** s from the pros.

The Bottom Line: It's More Than Just the Lowest Price

Let's be honest, price matters. But choosing a supplier only because they gave the cheapest quote is one of the riskiest moves you can make. That low number often comes from cutting corners—maybe on material quality, maybe on inspection time, or maybe by using worn-out tools.

Think of it this way: you're buying a successful project outcome, not just a piece of metal or plastic. A slightly higher price from a communicative, quality-focused partner that delivers on time is almost always cheaper in the long run than the headache of dealing with a failed part from the low bidder.

In my own experience, the best partnerships are built on this understanding. The goal is a smooth process and parts that work perfectly when they arrive.

Ready to put this guide into action? We've built our entire service around being that reliable, communicative partner. If this approach resonates with you, why not start a conversation with our team today? 👇

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque