Ever get stuck because you need a custom aluminum part, but have no idea about the cost? You're not alone. 😥 Figuring out the price for aluminum profile CNC Machining can feel like a mystery, especially when you're budgeting for a project. The truth is, there's no single "one-size-fits-all" price tag. But don't worry, we're going to break it down so you'll know exactly what you're paying for.

So, How Much Does It Actually Cost?

Let's cut to the chase. For standard aluminum profile machining, you might be looking at a range from $50 to $200 per hour for machine time, or $50 to $150 per part for simpler components. But please, take these numbers with a grain of salt. The final price is a mix of several ingredients, almost like a recipe. One small change can alter the whole cost.

What Really Drives the Price Up or Down? 🧐

Think of the cost as being built from a few key pieces:

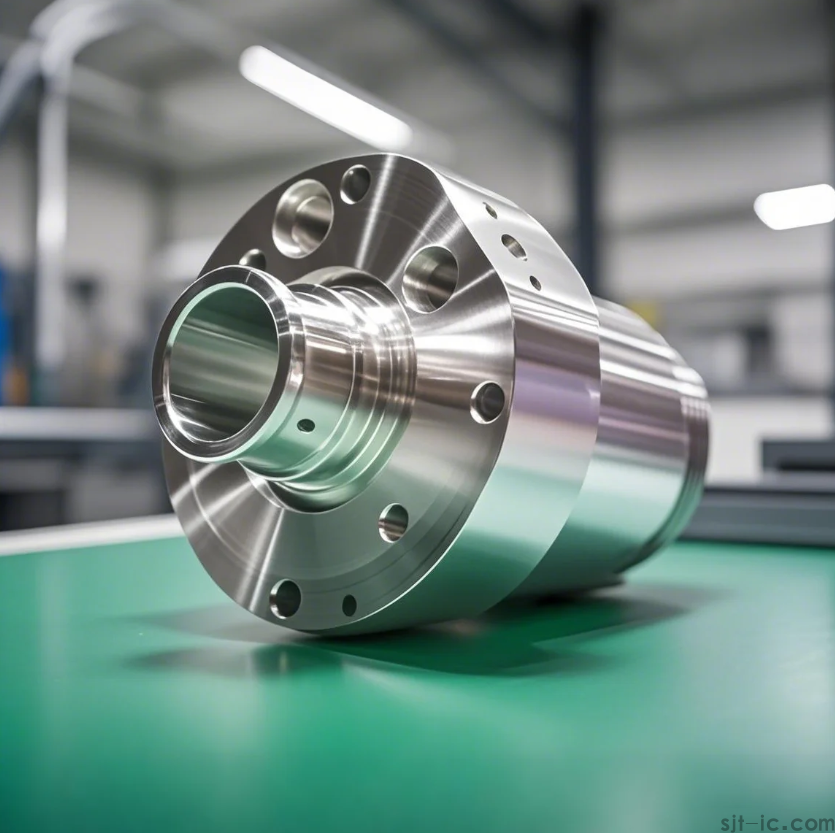

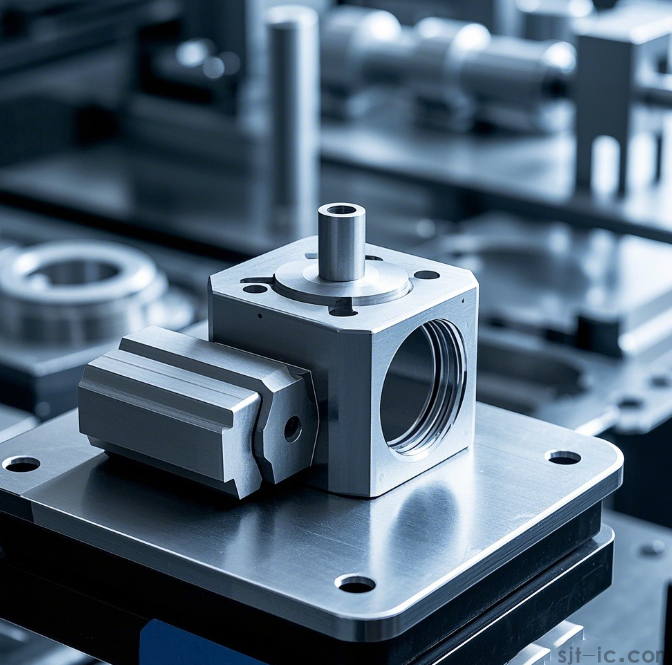

1. The Part's Design & Complexity: This is a huge one. A simple bracket with a few holes is worlds apart from a complex housing with intricate curves and tight tolerances. More complex shapes mean the machine has to work longer and might need special tools, which adds to the cost.

2. The Material & Quantity: We're talking aluminum profiles here, which are generally good value. But the specific grade can matter. And quantity is king! Ordering 10 pieces will have a much higher cost per part than ordering 1,000. Spreading the setup cost over more parts makes each one cheaper.

3. Machining Time & Labor: This is straightforward—the longer a part sits in the machine, the more it costs. Labor for setup and operation is baked into this hourly rate.

4. Finishing Touches: Do you need a smooth brushed look? A colored anodized finish? These post-processing steps add extra time and materials, so they add to the final bill.

My Personal Take on Getting a Good Deal

From what I've seen, many people focus only on the per-part price. However, I'd suggest looking at the total value. A slightly higher price from a supplier who really understands your design and catches potential issues might save you from expensive mistakes down the line. It's not always about finding the cheapest option; it's about finding the most reliable one for your needs. That being said, you definitely don't want to overpay for no reason.

How to Get the Most Accurate Quote (Without the Surprises) 💡

To get a quote that matches the final invoice, you need to give your machining partner clear information. Here’s what they need from you:

- Clear Drawings or 3D Files: This is the most important thing. The more detail, the better.

- Material Specification: Tell them exactly which aluminum alloy you need.

- Quantity You Need: Be clear about how many parts you want now, and possibly in the future.

- Surface Finish Requirements: Let them know if you need any special coating or treatment.

Providing all this up front makes the quoting process fast and accurate for everyone.

Ready to Get Your Exact Price?

Now that you know what goes into the cost, you're in a much stronger position. You can have a smarter conversation with potential suppliers and understand the quotes they provide. The best way to know your specific cost is, of course, to ask for a quote based on your unique part.

If you have a design ready, why not get a real number? Our team is here to provide you with a fast and transparent quote. Just send us your files and requirements, and we'll help you bring your project to life. 😊

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque