Stuck with a brilliant product idea but worried about sky-high machining costs for your first small run? You're not alone. Finding a budget-friendly CNC Machining service for small batches can feel like searching for a needle in a haystack. Big shops often have high minimum orders, leaving startups and innovators in the lurch. So, what's the secret to getting quality parts without blowing your budget? Let's dive in and uncover the practical steps you can take right now. 🤔

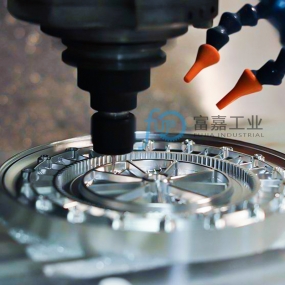

Why is Small Batch CNC Machining So Expensive? (And How to Beat It)

First things first, let's tackle the "why." CNC machines aren't cheap to run. There's programming time, setup, and machine calibration. For a giant order, this cost gets spread thin. But for a small batch, that same setup cost is shouldered by just a few parts, making each one pricier. It's like splitting a pizza; the more people, the cheaper it gets for everyone.

But here's the good news: This isn't a dead end. Many modern machine shops are now geared towards low-volume manufacturing. They use smart software to quote faster and have strategies specifically to make small batch projects more affordable. The key is knowing where to look and what to ask for.

Smart Moves to Slash Your CNC Machining Costs 🛠️

You don't have to just accept the first quote you get. A few clever choices can make a huge difference in your final bill.

1. Be Flexible with Your Materials: Sometimes, the fancy material you picked is driving the cost way up. Ask the machine shop if there's a more common, cost-effective alternative that still meets your strength and finish needs. A simple switch can save you a bundle.

2. Simplify Your Design: This is a big one. Every single tight tolerance, deep pocket, and complex surface adds machining time and cost. Go over your design with a fine-tooth comb. Can a radius be slightly larger? Can a tolerance be a bit looser without hurting the part's function? Designing for manufacturability is your best friend for saving money.

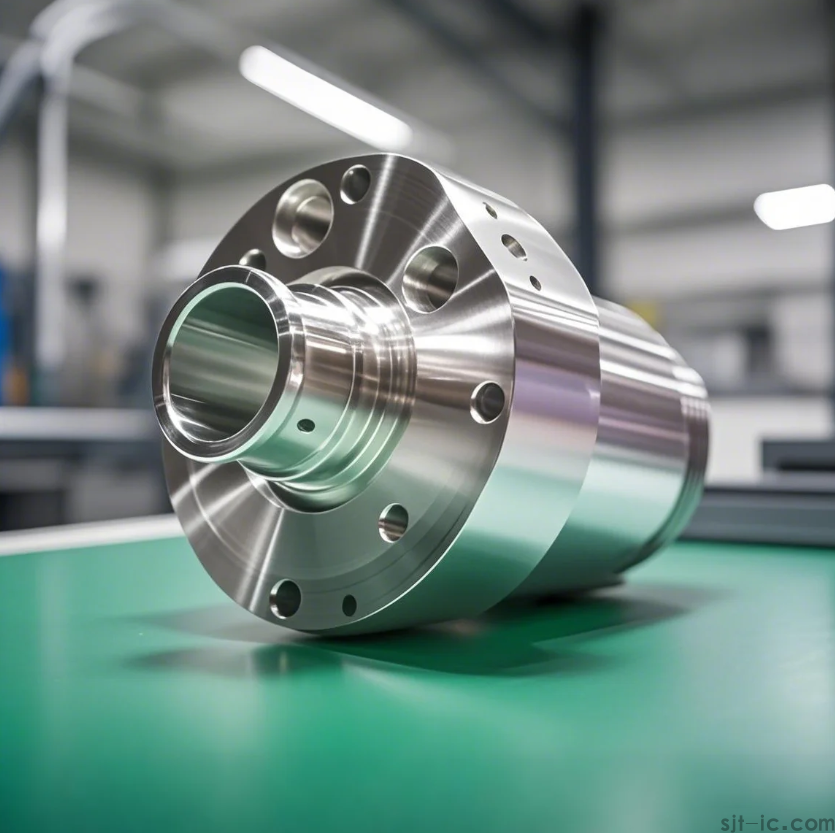

3. Choose the Right Finishing: That mirror-perfect, aerospace-grade finish looks amazing, but do you really need it? Standard "as-machined" finishes are often perfectly functional and much cheaper. Be realistic about the surface finish your project actually requires.

Where to Actually Find These Budget-Friendly Shops

Okay, so you've optimized your design. Now, where do you find these mythical affordable shops? The landscape has changed.

While big, traditional factories still exist, the rise of digital manufacturing platforms has been a game-changer. These online services connect customers with a network of machine shops. They automate the quoting process, which drives down overhead and often results in more competitive pricing for prototype and low-volume work. It's worth getting quotes from both these platforms and smaller, specialized local machine shops to compare.

From my own experience, I've noticed that smaller shops specializing in prototyping are sometimes more hungry for your business and can offer more personalized, cost-conscious service. They understand the needs of inventors and small businesses better.

Your Blueprint for a Smooth (and Affordable) First Order

Ready to take the plunge? Here’s a simple plan to make your first order a success.

Step 1: Prepare Your Files. Have a clean 3D CAD file (like a .STEP or .IGES) ready. This avoids confusion and extra charges for file repair.

Step 2: Get Multiple Quotes. Don't just go with the first option. Send your files to 3-5 different services or shops. This gives you a clear picture of the market rate.

Step 3: Communicate Clearly. When you get a quote, talk to them! Ask questions like: "Is there anything in my design that's making this more expensive?" or "What would be the price break for 50 units vs. 100?" A good partner will give you feedback.

Step 4: Start Small. If you're nervous, order a single prototype first to check the quality before committing to the full small batch production run.

Finding a true partner for your small batch CNC machining needs is totally possible. It requires a bit of homework and smart design choices, but the payoff—a high-quality product that fits your budget—is absolutely worth it. The manufacturing world is adapting, and affordability is no longer out of reach for the little guy. 🚀

Got a design ready? Don't let cost fears stall your project. Get a real, personalized quote for your parts today and see for yourself. Our team is here to help you navigate the process and find a solution that works for your vision and your wallet. Reach out to our online consultants now for an instant quote!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque