Ever had an automation project hit a snag because a tiny, supposedly 'precision' part didn't fit right? 🤔 It’s frustrating, wastes time, and costs money. If you're a procurement manager or engineer sourcing components, you know the headache. This article cuts through the noise and shows you exactly what matters when picking a precision automation parts machining manufacturer.

Why is "Precision" Such a Big Deal Anyway?

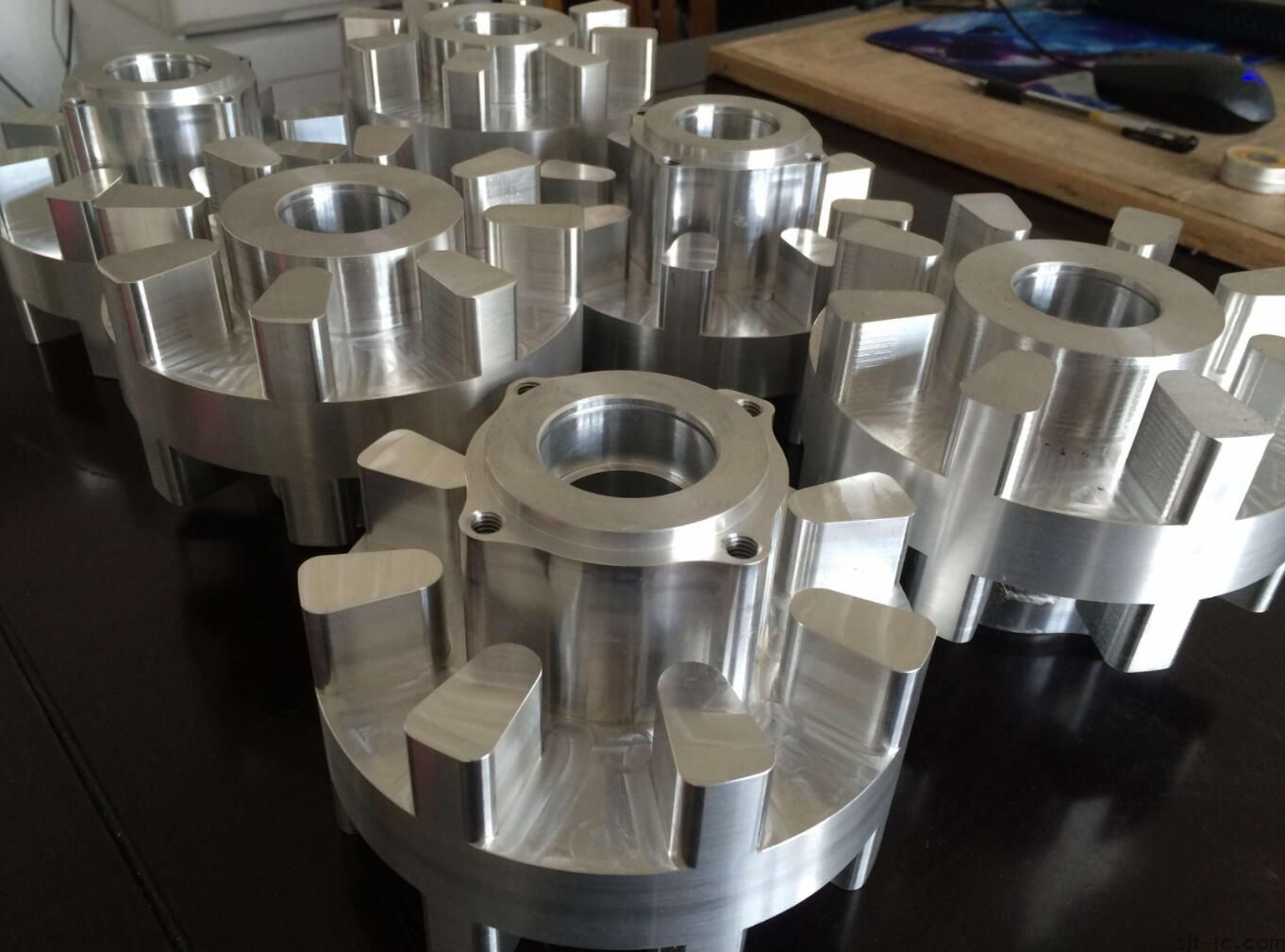

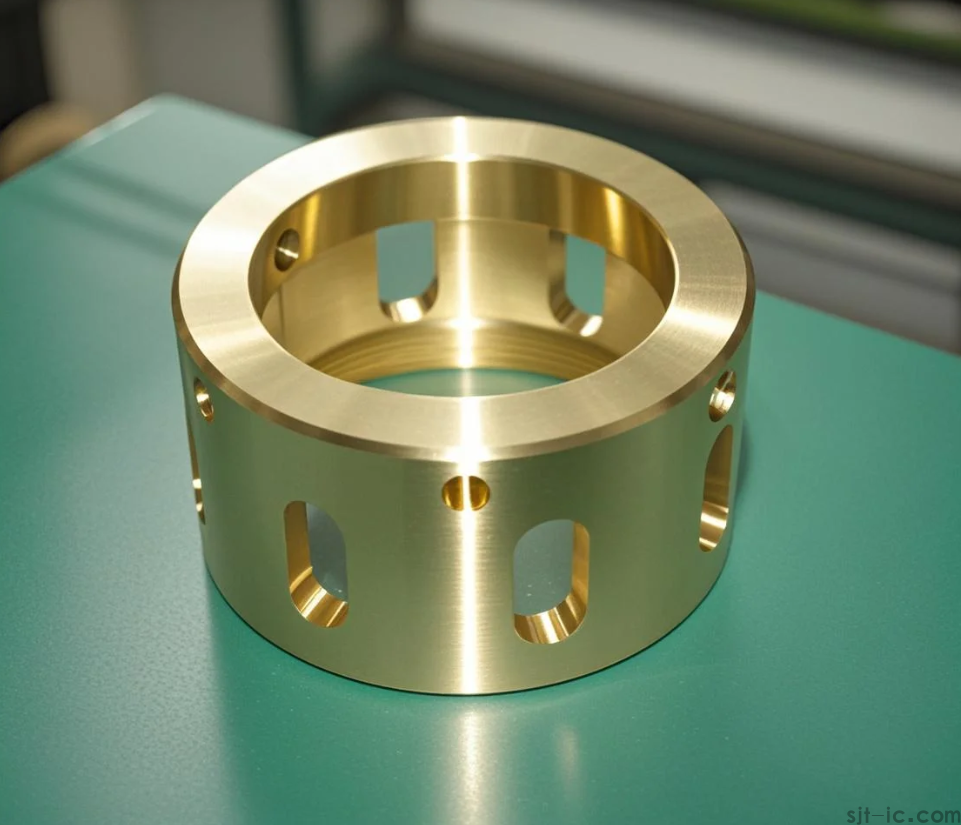

Precision isn't just a fancy word we throw around. In automation, it's the difference between a machine that runs smoothly for years and one that breaks down every other week. A high-precision part ensures seamless assembly, reduces vibration and wear, and ultimately, keeps your production line humming. While many shops claim to do "precision" work, the real test is in the final fit and function of the part in your system.

Key Thing #1: Check Their Tech and Capabilities 🛠️

Don't just take their word for it. A reliable manufacturer for your automation components should be upfront about what machines they use. Look for:

• Multi-axis CNC machines (Think 4-axis or 5-axis). This isn't just for complex shapes; it means the part can be finished in fewer setups, which boosts accuracy.

• Quality Control Tools: Ask about their inspection process. Do they use CMMs (Coordinate Measuring Machines) or laser scanners? This is a big deal for verifying tight tolerances.

• Material Experience: Can they handle everything from aluminum to tough stainless steels or even engineering plastics? Your application dictates the material.

Key Thing #2: It's More Than Just Making a Part

Here's a thought: the best manufacturers act like partners. This means they think ahead about the entire lifecycle of your project. It’s not just about hitting a drawing spec.

• Design for Manufacturability (DFM): A good partner will review your designs and might suggest small changes that make the part easier (and cheaper) to make without hurting its function. It’s a collaborative effort.

• Consistent Quality Over Time: Anyone can get one batch right. The challenge is doing it for the tenth reorder, two years later. This consistency is what keeps your automation reliable.

• Communication is Key: You need a contact who understands your technical needs and can give you straight answers, not just a salesperson.

Key Thing #3: Understanding the Real Cost

We all want to save money, but the cheapest option for machined parts can be the most expensive in the long run. Think about the cost of downtime, rework, or a failed component on your production line.

• Price vs. Value: A slightly higher price from a manufacturer with better quality control and engineering support offers far more value. It’s an investment in peace of mind.

• Hidden Costs: Delays, poor communication, and parts that need you to "make them fit" are all hidden costs that add up quickly.

That being said, a premium price doesn't automatically mean premium service. The goal is to find that sweet spot where the cost aligns perfectly with the quality and service you receive.

So, What's the Next Step?

Finding the right precision automation parts machining manufacturer is a crucial step. It requires looking beyond the brochure and evaluating their real-world capabilities and willingness to partner with you. We've laid out the blueprint—the key areas to focus on to make an informed decision.

Ready to discuss your specific project requirements with a team that gets it? Our technical experts are here to help. Reach out to our online team now for a free, no-obligation project review. 👇

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque