Hey there, are you a purchasing manager or engineer struggling to find a reliable supplier for professional CNC Machining stainless steel parts? You need high precision, durability, and a smooth process, but maybe you've faced issues with quality consistency or communication delays. It's a common headache. Let's break down what truly matters when sourcing these components and how to identify a partner that gets it right.

What is Professional CNC Machining for Stainless Steel?

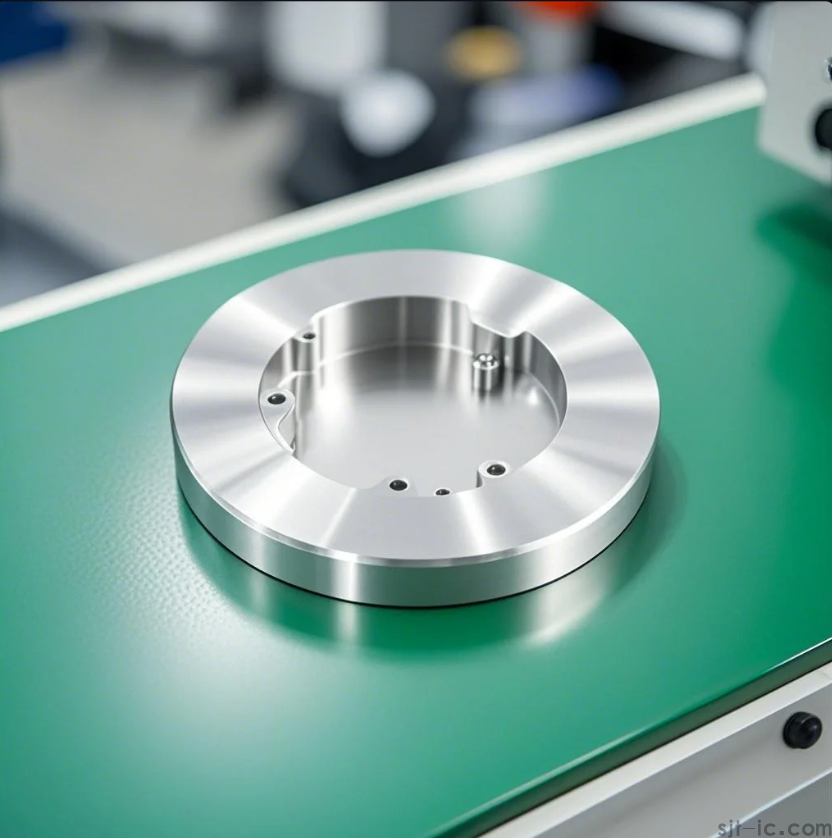

At its core, it's about using computer-controlled machines to cut and shape stainless steel into precise parts. But it's not just that. A professional service means they understand the material's behavior—like how it can get hard during machining or how to achieve that perfect surface finish you need. It's the difference between a part that just fits and one that lasts for years in your application.

Why is Stainless Steel So Tricky to Machine?

Stainless steel is tough and can work-harden if not machined correctly. This can lead to tool wear and parts that don't meet spec. A pro shop knows to use the right cutting tools and coolants to manage heat and pressure. They also get that the material grade matters a ton—like 304 for general use or 316 for corrosive environments. Choosing the wrong one might cause your project to fail down the line.

What Should You Look for in a CNC Machining Partner?

First, check their experience with stainless steel. Do they have case studies or samples? Second, look at their quality control process. Do they measure parts at every stage? I've seen shops that skip this, and it leads to surprises. Third, communication—can they explain the process in plain English? If they're vague, that's a red flag. A good partner acts like an extension of your team.

- ✅ Proven track record with similar projects

- ✅ Clear quality checks and documentation

- ✅ Responsive and technical support

How to Ensure Your Parts Meet Expectations?

Start with a clear drawing or 3D model, and discuss critical tolerances upfront. Sometimes, designers specify tight tolerances everywhere, but that drives up cost. A professional might suggest where to loosen up without affecting function. Also, talk about surface finish options—like brushed or polished—based on your product's use. It's these details that separate a good part from a great one.

What Are Common Mistakes to Avoid?

One big mistake is focusing only on price. Cheaper bids often mean corners cut on tooling or inspection. Another is not planning for material lead times, which can delay your project. And hey, I get it—budgets are tight. But remember, a part that fails costs way more in the long run. Perhaps it's better to view this as an investment in reliability.

On that note, if you're sourcing components for machinery or products, having a trusted supplier makes all the difference. For tailored solutions and support, feel free to reach out to our team online—we're here to help you navigate these choices. 😊

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque