Ever held a medical device and felt that something was... off? Maybe the seams weren't quite right, or the material felt cheap. For procurement managers and engineers, this isn't just about feel; it's a red flag. 🚩 Finding a trustworthy partner for medical device housing CNC Machining is tough. You're not just buying a part; you're trusting someone with your product's safety, durability, and first impression. So, how do you sift through the options and find a reliable CNC machining service that gets it right? Let's break it down.

Why is the "Right" CNC Service So Critical for Medical Housings?

Think of the housing as the device's bodyguard. It's not just a pretty face. A well-machined housing ensures structural integrity, protects sensitive internal electronics from the environment, and must be easy to clean and sterilize. A single flaw—a tiny crack, an imprecise fit—can lead to device failure. While many shops can cut metal, only a select few truly understand the strict standards and zero-tolerance for error in the medical field. This is perhaps the biggest hurdle.

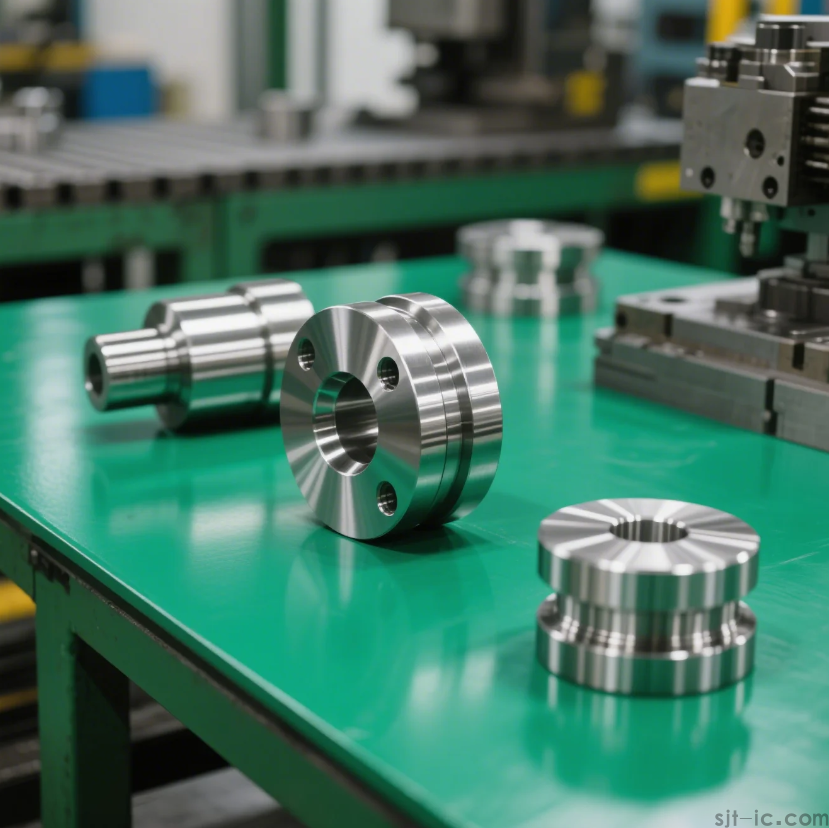

What Materials Work Best and Why?

This is where the conversation often starts. The common picks are medical-grade stainless steel, aluminum alloys, and certain engineering plastics. Each has its own story.

Stainless Steel: The champion of strength and sterilization. It's a beast when it comes to handling repeated autoclaving. But, it's heavier and can be tougher on your cutting tools.

Aluminum Alloys: My go-to for a great balance. It's lighter than steel, has good strength, and is generally easier to machine, which can sometimes mean lower costs. Perfect for handheld or portable devices.

Medical Plastics (like PEEK or PC): These are the lightweights and electrical insulators. They're fantastic for certain applications, but you have to be super careful about their behavior during machining and long-term durability.

Anyway, the "best" material isn't a universal rule. It's a dance between your device's function, weight needs, and budget.

What Machining Tolerances Should You Expect?

In simple terms, tolerance is how much a dimension is allowed to vary from the perfect number. For a medical housing that needs to snap together perfectly or seal out moisture, this is everything.

You should be looking for a service that consistently holds tolerances within ±.05 mm or even tighter for critical features. This precision ensures that every single housing they make for you will fit with its counterparts and internal components without any guesswork or force. If a supplier is vague about their capability here, it's a major warning sign.

How to Really Vet a Potential Supplier?

Okay, so you have a few quotes. The prices look similar. How do you choose? Don't just look at the machine; look at the mind behind it.

Ask About Their Medical Experience: Have they made housings before? Can they show you examples? A shop experienced with automotive parts might not grasp the unique needs of a medical device.

Discuss Quality Control Upfront: Do they have a documented process? How do they check parts? Do they provide inspection reports with each batch? This is non-negotiable.

Communication is Key: Pay attention to how they communicate during the quoting process. Are they asking smart questions about the function of the housing? Or are they just accepting your files without comment? A partner will ask questions; a order-taker will not.

From my own experience, the best partnerships are formed when the machining service acts like an extension of your own engineering team. They spot potential issues in the design that could cause machining problems or weaknesses later on.

Choosing the right partner for your medical device housing is more than a purchase—it's a strategic decision. It impacts your timeline, your product's quality, and ultimately, your brand's reputation. You need a service that offers more than just a machine; you need one that offers peace of mind. 🛡️

Have a specific project or a tricky housing design you'd like to discuss? Our engineering team is ready to provide insights. Reach out to our online service team for a confidential consultation.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque