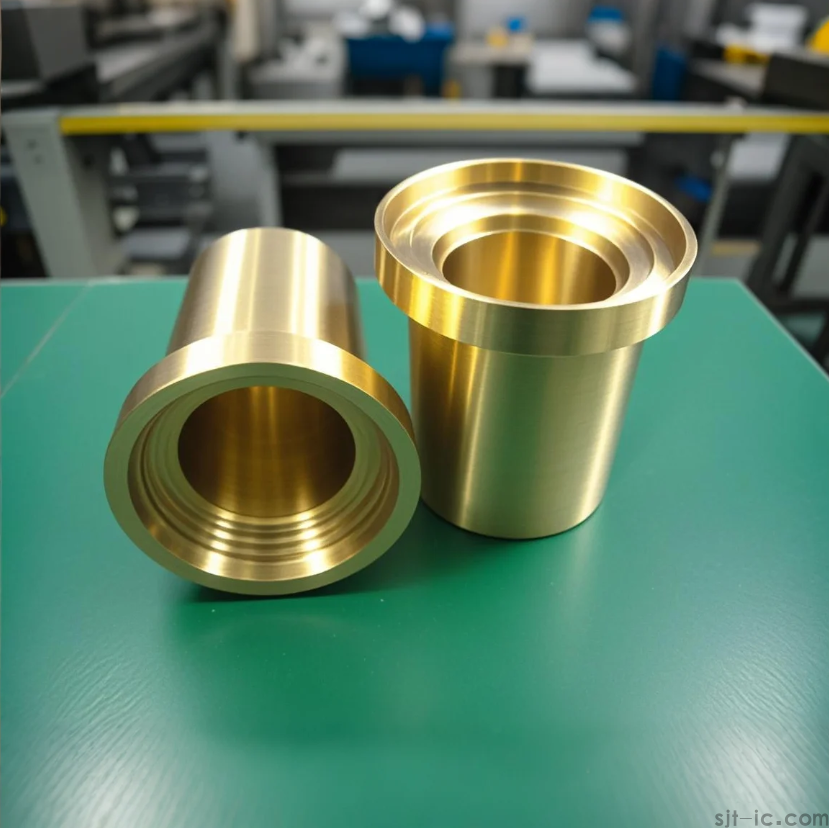

Hey there! If you're sourcing CNC machined brass parts, you've probably noticed that not all brass alloys are created equal. I've seen engineers and procurement managers spend weeks troubleshooting parts that tarnish too quickly or machines that gum up during production – often because they picked the wrong brass material from the start. 🚨

Today, let's cut through the confusion and answer the burning question: What brass alloy should you actually choose for your CNC project? I'll share not just textbook answers but real-world insights from the machine shop floor.

What Exactly Makes Brass Good for CNC Machining Anyway?

Brass is like that reliable friend who rarely lets you down in the workshop. But why? The secret sauce is copper and zinc – the two main ingredients. The zinc acts as a self-lubricant during cutting, which means your tools last longer and you get smoother finishes. Pretty neat, right?

However – and this is crucial – the exact copper-to-zinc ratio changes everything. Higher copper content typically means better corrosion resistance, while more zinc often improves machinability. It's this balancing act that determines which brass you should pick.

Free-Cutting Brass (C36000): The Workshop Favorite

If you've spent any time around CNC shops, you've definitely encountered C36000. It's the go-to choice for about 80% of general brass components, and for good reason:

• Unbeatable machinability: Rated 100% on the machinability scale (yes, that's the top score!)

• Great finish quality: Parts come out looking clean with minimal effort

• Reasonably priced: You get performance without breaking the bank

I've used C36000 for everything from plumbing fittings to electrical connectors. It just works. But here's the catch: it's not the best choice if your parts will face constant water exposure or need superior corrosion resistance.

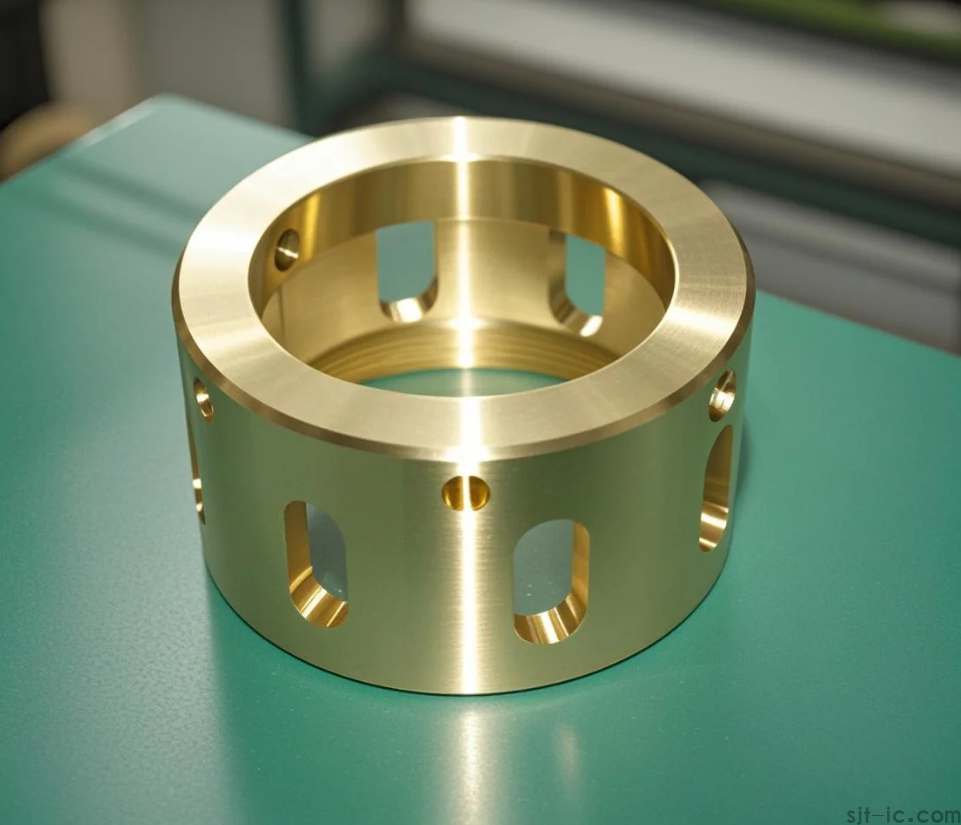

When Should You Consider Other Brass Alloys?

While C36000 is fantastic, it's not a one-size-fits-all solution. Sometimes other brass alloys might serve you better:

• Naval brass (C46400): Your best bet for marine environments ⚓

• Architectural bronze (C38500): Perfect when appearance matters most

• Leaded brass (C35300): A solid alternative when C36000 isn't available

The specific mechanism of how lead content affects machinability across different brass types could use more research, but from my experience, even small amounts make a noticeable difference in cutting smoothness.

Real-World Factors That Actually Matter in Brass Selection

Technical specs are one thing, but here's what I've learned from actually making parts day in and day out:

• Lead content concerns: While leaded brass machines beautifully, there might be regulatory considerations for certain applications

• Post-processing needs: Some brass alloys take plating and finishing treatments better than others

• Supplier availability: Honestly, sometimes the "best" brass is the one your supplier actually has in stock

I've seen projects delayed for weeks waiting for that "perfect" alloy when a more available option would have worked just fine. Food for thought! 🤔

My Personal Take: Balancing Ideal vs. Practical in Brass Selection

After years in this business, here's my perspective: while C36000 free-cutting brass might be the optimal starting point for most CNC projects, the real art is knowing when to deviate. Don't get so caught up in finding the "perfect" material that you delay your entire production timeline.

Sometimes "good enough" now is better than "perfect" next month – especially when the performance differences between brass alloys in many applications are actually quite minimal. Just something to consider next time you're specifying materials! ✨

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque