Hey there, fellow engineers and procurement pros! 👋 Are you tired of dealing with CNC sliders that just don't fit right, wear out too fast, or cause headaches in your assembly line? You're not alone. Getting that perfect, smooth, and long-lasting slider component can feel like a constant battle. The secret often lies not just in the CNC machine itself, but in the precision machining process behind it. This guide is here to cut through the noise and give you some straight-to-the-point insights on how to achieve top-tier quality in CNC slider machining.

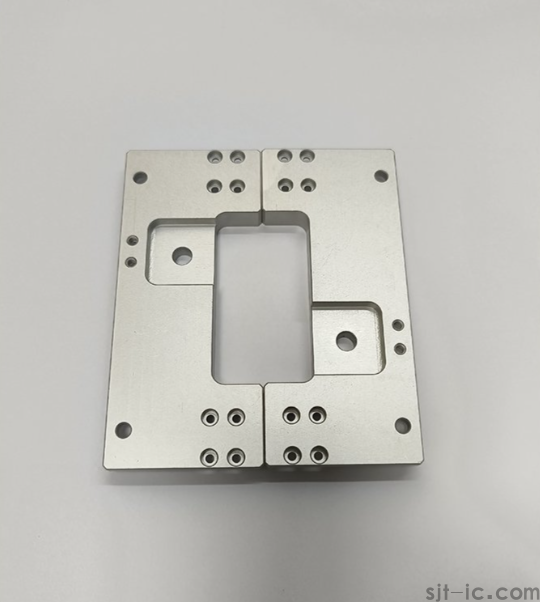

What Exactly is Precision CNC Slider Machining?

Let's start with the basics. When we talk about "precision CNC slider machining," what are we really getting at? It's not just about cutting a piece of metal into a slider shape. It's the entire process of using computer-controlled machines to create sliders with incredibly tight tolerances, superb surface finishes, and perfect geometries. Think of it as the difference between a rough sketch and a detailed blueprint—both are useful, but one is fit for a critical application. This process ensures that the slider moves smoothly, carries loads effectively, and has a long service life, which is what every project manager and engineer is aiming for.

Why is Material Choice Such a Big Deal?

This might seem obvious, but the material you choose is the foundation of everything. We all know that, right? But here's the thing: I often see projects where the material was an afterthought.

Common picks include:

• Aluminum Alloys: Great for when you need a light-weight part with good strength.

• Stainless Steel Your go-to for corrosion resistance and durability in harsh environments.

• Brass or Bronze: Sometimes used for their self-lubricating properties.

However, the specific grade and its properties—like hardness and machinability—directly impact the machining strategy. Picking the wrong one can lead to tool wear, poor surface quality, and a part that fails prematurely. The exact science behind why one alloy machines better than another, I have to admit, is a bit of a knowledge gap for me—the metallurgy gets pretty deep!

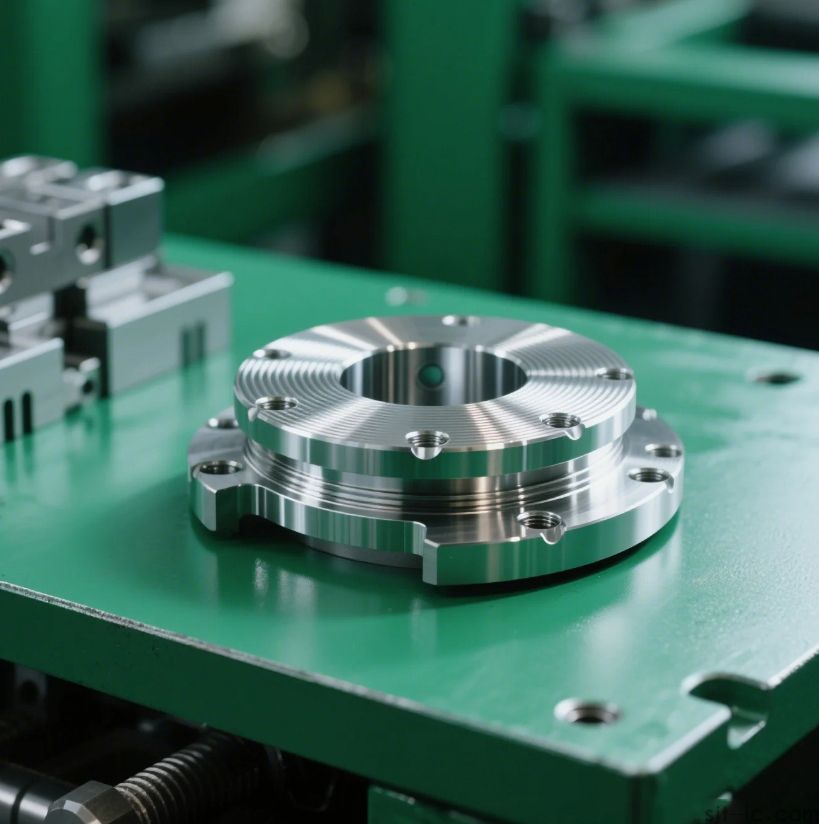

How Can We Achieve a Super Smooth Surface Finish?

A rough slider is a noisy, inefficient, and short-lived slider. Achieving that mirror-like finish isn't just for looks; it's crucial for reducing friction and wear.

Here are a couple of things that have worked in my experience:

• Tool Path Strategy Matters: Using the right CNC programming techniques, like climb milling, can significantly improve surface quality compared to conventional milling.

• Don't Rush the Cuts: Slower feed rates and higher spindle speeds often produce a finer finish. It's a balance between speed and quality.

But wait, there's a catch. While a smoother finish is generally better, sometimes a specific texture can be beneficial for retaining lubricant. This is where the application's specific needs really come into play.

What About Holding Tight Tolerances? Is It All About the Machine?

We all want those sliders to be made to exact specifications, with no deviation. It's easy to think that buying the most expensive CNC machine will solve all tolerance problems. While a modern, well-calibrated machine is absolutely essential, it's only part of the story.

Other factors that can mess with your tolerances:

• Thermal Expansion: The machine and the part itself heat up during machining. If this heat isn't managed, the dimensions can shift, perhaps suggesting that environmental control is more important than we think.

• Tool Wear: A slightly worn tool won't cut as accurately, leading to parts that are out of spec.

• Workholding: If the raw material isn't held securely and rigidly, it can vibrate or move, ruining precision.

So, it's a holistic process. The machine is vital, but without attention to these other details, you might not get the consistent results you're paying for.

My Personal Take: The Overlooked Role of Prototyping

Here's a bit of my own perspective. Everyone is in a rush to get to mass production. But I've found that investing time in a small-batch prototype run can save countless resources down the line. It lets you physically test the slider in its intended application, check the fit, the movement, everything. You can catch a design flaw or a machining issue when it's cheap to fix, not after you've made ten thousand pieces. It's a step that, in my view, separates a good procurement process from a great one.

Ultimately, nailing precision CNC slider machining is about understanding that it's a chain of interconnected steps. From material selection to the final quality check, each link needs to be strong. Hopefully, these points give you a clearer picture and some practical ideas for your next project. 🤝

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque