Feeling overwhelmed by the sheer number of companies offering CNC services for your stainless steel project? You know you need precision and durability, but how do you sift through the options to find a partner you can truly trust for bulk production? Let's break down the key things to look for, beyond just the quoted price. 🤔

What Exactly Should I Look For in a CNC Manufacturer?

It's not just about finding someone who can make the part. For批量加工, you need a partner. Think about it: consistent quality across thousands of parts is a completely different ball game compared to a one-off prototype. The core things to vet are their experience with stainless steel, quality control systems, and their ability to be a reliable long-term partner.

Experience That Matters: Have They Done This Before?

Any shop can say they work with stainless steel. But you need proof. Ask them:

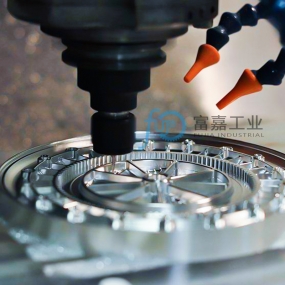

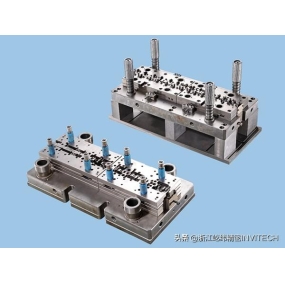

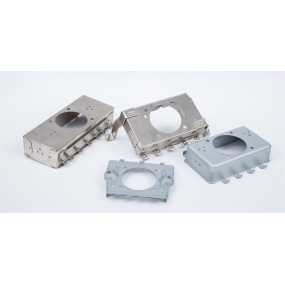

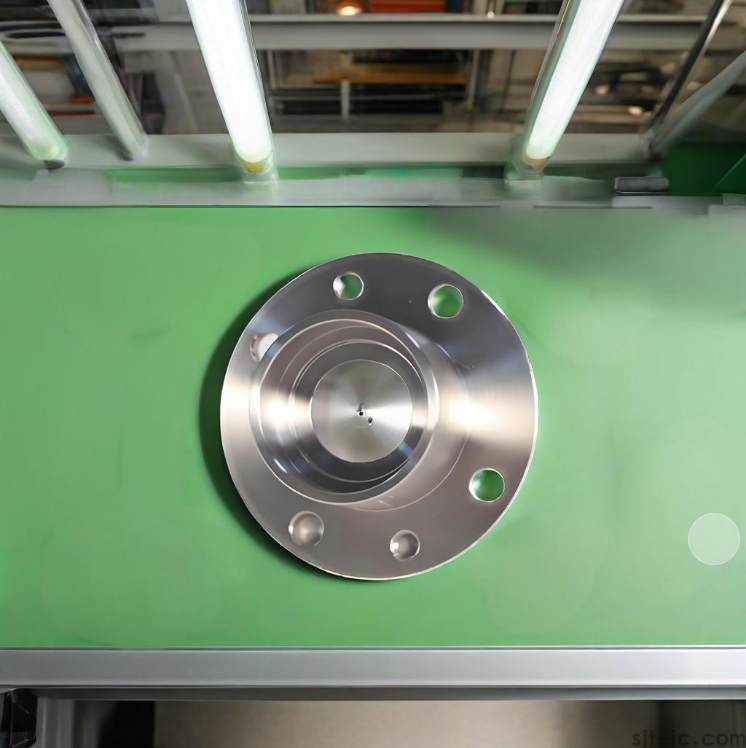

• Can you show me examples? A confident manufacturer will have a portfolio or case studies of similar projects.

• What grades of stainless do you commonly handle? Familiarity with 304, 316, or 303 suggests they know the material's quirks, like work hardening.

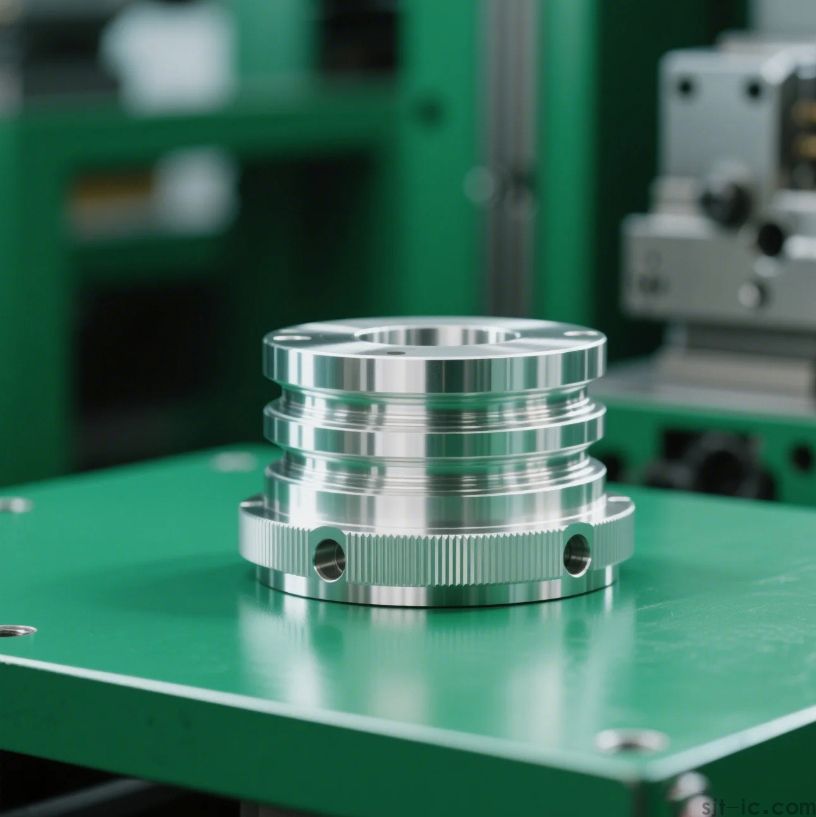

• What's your shop's setup? While the specific machine models might be their secret sauce, knowing they have multi-axis capabilities for complex geometries is a good sign. I often find that shops using newer equipment tend to have fewer issues with tool wear on tough materials like stainless, though this isn't a guaranteed rule.

How Do I Know the Quality Will Be Consistent in Every Batch?

This is the million-dollar question for bulk orders. One perfect sample part means nothing if the 100th one is out of spec.

• Ask about their inspection process. Do they just do a quick check, or do they have a documented First Article Inspection (FAI) and in-process checks? A proper FAI report is a green flag.

• Look for certifications. While ISO 9001 doesn't guarantee perfect parts, it does show a commitment to a structured quality management system. It proves they at least try to do things the right way, every time.

• Talk about communication. Will you get updates if there's a hiccup? A good partner will tell you about a potential delay, a bad one will just ship it late. This focus on clear communication and a solid quality control framework is, in my view, non-negotiable. However, it's worth mentioning that the exact correlation between a specific certification and on-the-ground part quality can sometimes be murky, as it heavily depends on the company culture.

But What About Communication and Project Management?

You're not just buying machine time; you're buying a service. A smooth process saves you countless headaches.

• Who is your single point of contact? Dealing with five different people is a recipe for confusion.

• How do they handle design feedback? A valuable manufacturer will point out potential issues in your design that could save cost or improve manufacturability. This is where they transition from a vendor to a partner.

• Understand their quoting process. Is it transparent? Do they break down costs, or is it one mysterious number? A detailed quote often reflects a detailed-minded operation.

Making the Final Decision: It's More Than Just Cost

Yes, the stainless steel CNC Machining cost per part is crucial for your budget. But the cheapest option can often become the most expensive due to delays, reworks, or quality rejects. Weigh the price against everything else we've discussed: their proven experience, robust quality control, and professional project management.

Sometimes, paying a little more upfront for a manufacturer that communicates well and has a track record for consistency is the most cost-effective choice in the long run for your bulk production needs.

Ready to discuss your specific stainless steel project requirements and get a transparent evaluation? Reach out to our technical team today for a personalized consultation. 👇

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque