Are you a procurement manager or business owner struggling with high expenses in CNC titanium alloy machining? 😫 You're not alone! Many professionals face this issue, but the good news is, there are simple ways to cut costs without sacrificing quality. In this article, we'll dive into practical tips and insights to help you save money while maintaining top-notch results. Let's get started and explore how you can optimize your machining processes today! 🚀

What Makes CNC Titanium Alloy Machining So Expensive?

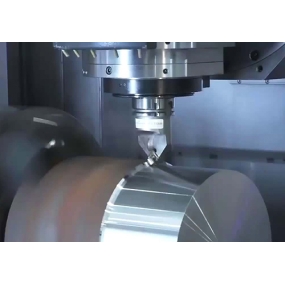

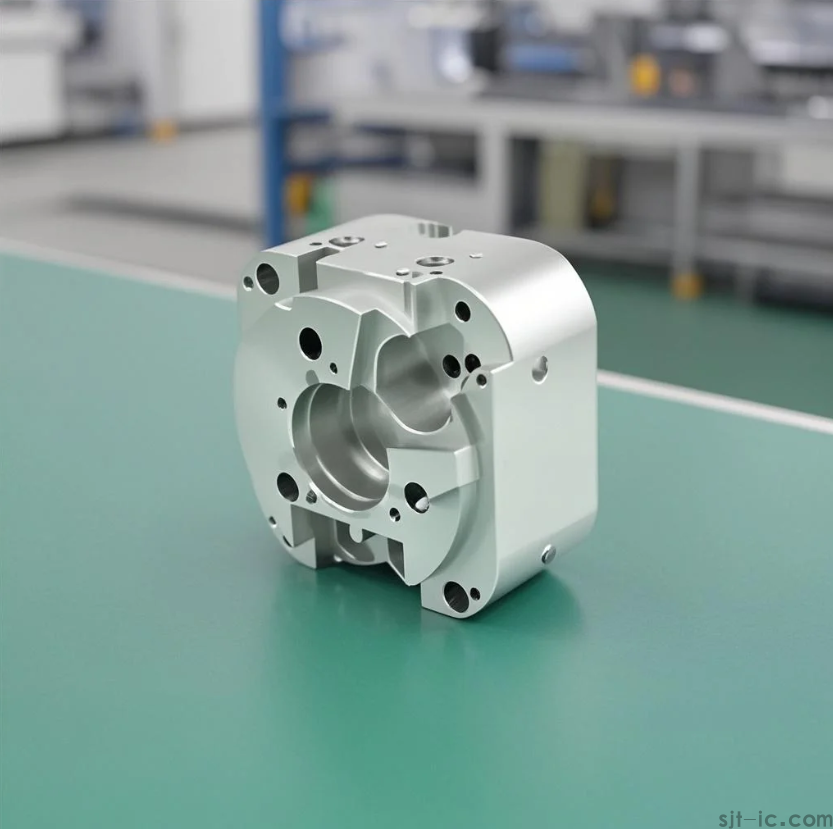

First off, let's address the big question: why does CNC Machining for titanium alloys often come with a hefty price tag? 🤔 Titanium is a tough material—it's strong, lightweight, and resistant to corrosion, but that also means it's hard to work with. Machines need to run slower, use special tools, and require more energy, which all add up. Plus, factors like material waste and labor costs play a role. However, understanding these elements can help you identify where to trim expenses. For instance, did you know that optimizing tool paths might reduce machining time? That's a key area to focus on!

How Can You Actually Lower CNC Titanium Machining Costs?

Now, for the answer you've been waiting for: reducing costs isn't just about cutting corners; it's about smart strategies. 🧠 Here are some effective ways to save money:

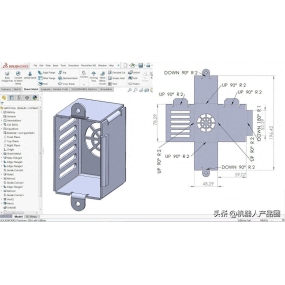

- Optimize design for manufacturability: Simplify parts to reduce machining time and material use. For example, avoid complex shapes that require extra steps.

- Choose the right tools and settings: Using high-quality cutters and adjusting speeds can extend tool life and minimize downtime. I often use this approach in my projects, and it really pays off!

- Batch processing: Group similar jobs together to save on setup costs. This is a common trick in the industry that many overlook.

But wait, there's more—while these methods work, the exact savings might vary depending on your setup. Some experts say that proper cooling systems can cut costs by up to 15%, but the mechanism behind this isn't fully clear yet. Overall, focusing on efficiency is key. 😊

What Are the Common Mistakes That Inflate Costs?

Let's be real: sometimes, we shoot ourselves in the foot by making simple errors. 💥 In CNC titanium machining, common pitfalls include over-tightening tolerances or ignoring maintenance schedules. For instance, if you demand ultra-precise fits when they're not needed, you're just adding unnecessary hours to the job. I've seen cases where this doubled the cost! On the flip side, regular machine checks can prevent costly breakdowns. So, ask yourself: are you reviewing your specs thoroughly? It might be time to reassess.

How Does Material Selection Impact Your Budget?

Another big factor is the type of titanium alloy you pick. 🛠️ Some grades are easier to machine than others, which can lower expenses. For example, Grade 5 titanium is popular but might require more effort compared to others. Although, I have to admit, the full impact of alloy choices on long-term costs isn't something I've dug deep into—there might be hidden trade-offs. Still, discussing options with your supplier can lead to better deals. Think about it: a small change in material could mean big savings without compromising performance.

Ready to Take Action and Save on Your Next Project?

By now, you've got a solid grasp on cutting CNC titanium alloy machining costs. From optimizing designs to avoiding common errors, these steps can make a real difference. 💡 Remember, every dollar saved adds up for your business. If you're looking for personalized advice or want to explore more, why not reach out to our online team? They're here to help you tailor these tips to your specific needs. Don't let high costs hold you back—start implementing these ideas today and see the benefits for yourself! 👍

Just a quick note: while these strategies are based on general practices, results can vary. I'd love to hear your experiences—drop a comment if you've tried any of this!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque