Hey there, fellow procurement managers and engineers! 👋 Are you tired of sourcing CNC machined sprockets that just don't meet the mark? You know, the ones with inconsistent teeth that cause excessive wear, or deliveries that are always late, throwing your entire production schedule into chaos? You're not alone. Many professionals face this very issue, where the promise of precision falls short in reality. This guide is here to cut through the noise and give you a clear, inside look at what truly defines quality in precision CNC sprocket machining. Let's dive in and demystify the process together!

What Exactly is Precision CNC Sprocket Machining Anyway?

At its heart, precision CNC sprocket machining is about using computer-controlled machines to cut sprocket teeth from a solid block of metal with incredible accuracy. Think of it like a super-skilled sculptor, but one that works in thousandths of a millimeter, every single time. The main goal? To create sprockets that fit perfectly, run smoothly, and last a long, long time. While the basic idea is simple—a toothed wheel that engages with a chain—the devil is truly in the details. Getting every tooth profile, pitch, and hardness exactly right is what separates a mediocre component from a high-performance one. This precise manufacturing process is crucial for ensuring your machinery runs without a hitch.

Why Can't I Just Use Any Sprocket? The Real Cost of "Good Enough"

It's a fair question. Why stress over ultra-precision? Well, the answer often lies in the long-term costs. A sprocket that's "almost" right might work at first, but it will likely lead to a chain reaction of problems.

• Premature Wear and Tear: Imperfect teeth don't mesh with the chain properly. This causes friction, which wears out both the sprocket and the chain much faster than they should. You'll be replacing them before you know it.

• Noisy and Inefficient Operation: That annoying clunking sound in your machinery? It could be poorly machined sprockets. This noise is a sign of energy loss and vibration, which saps efficiency and can damage other components.

• The Domino Effect of Failure: In the worst-case scenario, a failed sprocket can bring an entire production line to a grinding halt. The cost of downtime often dwarfs the cost of the component itself.

However, it's worth mentioning that the exact relationship between a specific surface finish measurement and its direct impact on chain longevity is an area where I'd love to see more real-world data. The theory is clear, but practical applications can sometimes surprise you.

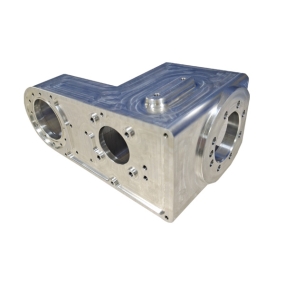

How is a Precision Sprocket Actually Made? A Peek Inside the Process

So, how do we achieve this so-called precision? It's not magic; it's a meticulous process. While the exact steps can vary between shops, the core stages are pretty consistent.

1. The Digital Blueprint (CAD): It all starts with a perfect digital design. Every curve, every tooth dimension is defined here. This file is the master plan.

2. Programming the Machine (CAM): Next, the digital design is translated into a set of instructions—called G-code—that the CNC machine can understand. This tells the machine exactly where to move and how fast to spin.

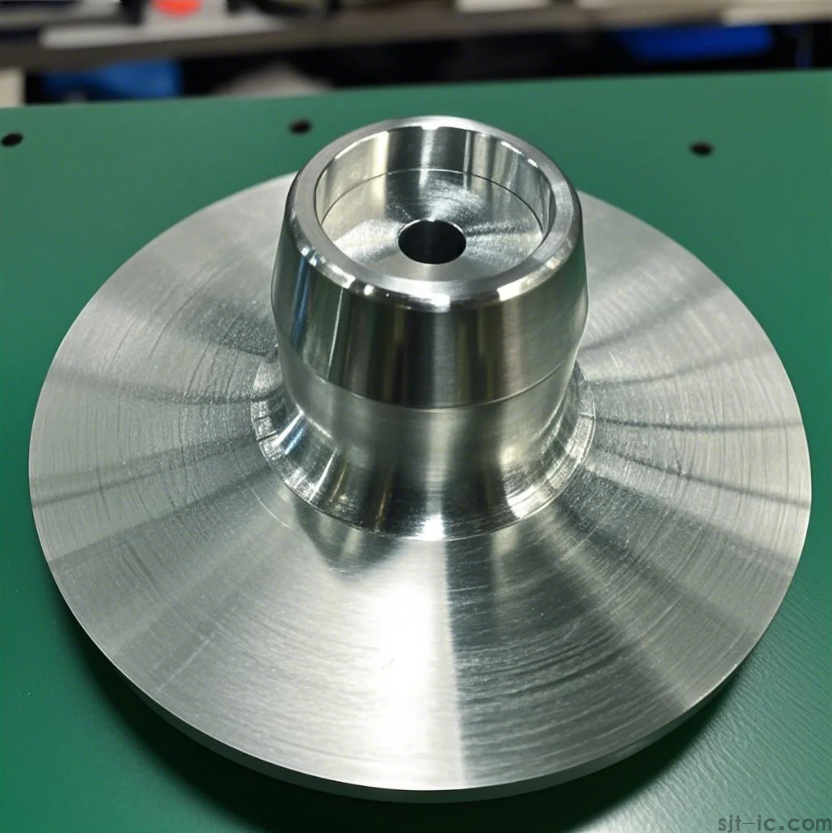

3. The Machining Ballet: This is where the action happens. A solid piece of material (like steel or stainless steel) is clamped down. Then, cutting tools whir around it, strategically removing material to carve out the perfect sprocket shape. The machine might perform roughing cuts to quickly remove bulk material, followed by finishing passes to achieve the final, smooth dimensions.

4. The Final Touches: After machining, the sprocket might be deburred (removing sharp edges), heat-treated to enhance its hardness and durability, and sometimes coated for corrosion resistance.

From my experience, the transition from roughing to finishing is a critical point. A shop that rushes the roughing process might introduce stresses that affect the final precision during the finishing cuts. It's a delicate balance between speed and accuracy.

What Should I Look For When Choosing a Machining Partner?

This is the million-dollar question. You're not just buying a part; you're buying a supplier's capability and reliability. Here are a few things to keep in mind.

• Don't Just Look at the Price Tag: The cheapest option is often the most expensive in the long run. Ask about their quality control process. Do they measure every critical dimension on every batch?

• Communication is Key: Can you talk directly to an engineer? A supplier that understands your application and challenges is worth their weight in gold. If they only talk about price and not about your needs, that's a red flag.

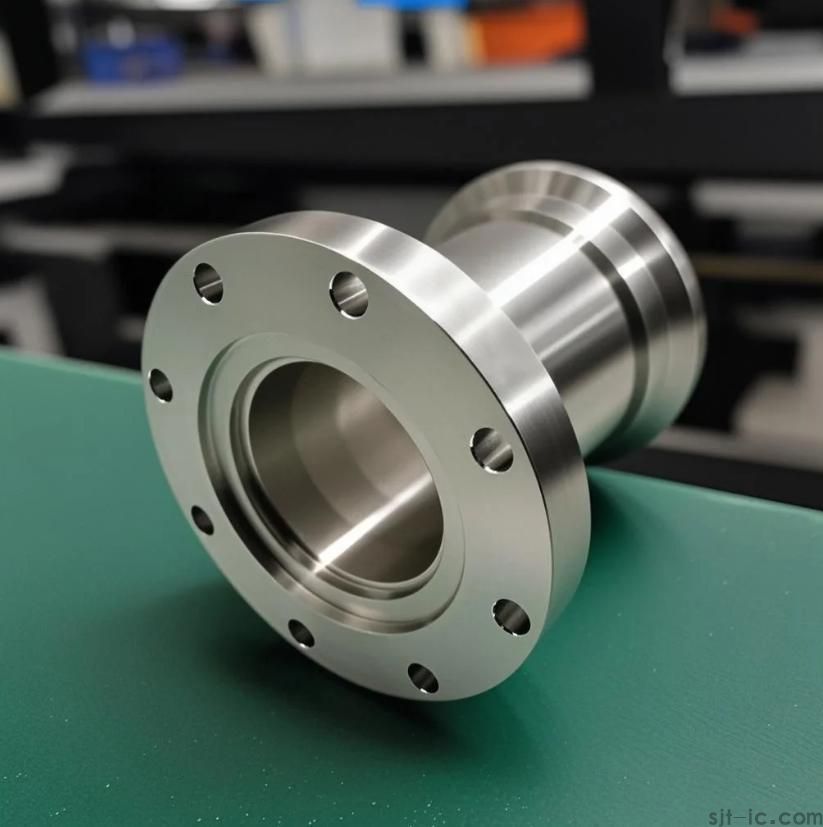

• Material Know-How: A good partner should be able to advise you on material selection. Is stainless steel the best choice for your corrosive environment, or would a treated carbon steel offer better value? Their expertise here is crucial.

That being said, I've found that the most reliable partners are those who are transparent about their limitations. If a supplier claims they can do everything perfectly, it might be a good idea to dig a little deeper. A bit of humility in this field usually indicates real expertise.

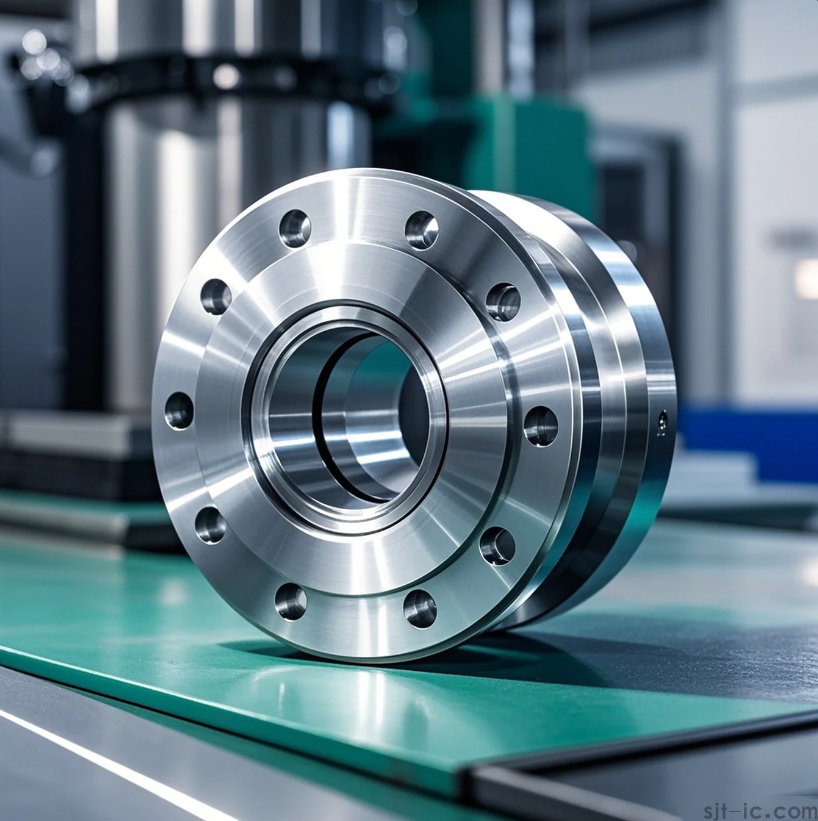

A Little-Known Factor That Can Make or Break Your Sprocket

Everyone focuses on the tooth profile, and rightly so. But there's another, often overlooked, aspect: the runout tolerance. In simple terms, this is how much the sprocket "wobbles" as it spins on its shaft. Even a sprocket with perfectly cut teeth will cause vibration and uneven wear if it has excessive runout. It's like a car tire that's out of balance; you'll feel it all the way through the system. When discussing your next order, asking about how they control and measure runout might just save you from a world of trouble down the line. This attention to detail is what I personally look for, and it often separates the good from the great.

Ultimately, investing in truly precision CNC sprocket machining is about more than just buying a part. It's about securing the smooth and reliable operation of your equipment, minimizing downtime, and building a partnership with a supplier you can trust. It's an investment in peace of mind. 🚀

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque