Hey there, fellow engineers and procurement managers! 👋 Are you sourcing parts for your electric vehicle project and feeling stuck between manufacturing options? You want something precise, reliable, and efficient, but you're not sure which method delivers the best value. Well, you're not alone. Many of us in the industry have faced this dilemma. Let's cut through the noise and talk about a method I frequently use and trust: CNC Machining. Why is it such a standout choice for EV components? Let's dive in and explore the key advantages. 🚀

What Exactly is CNC Machining for EV Parts?

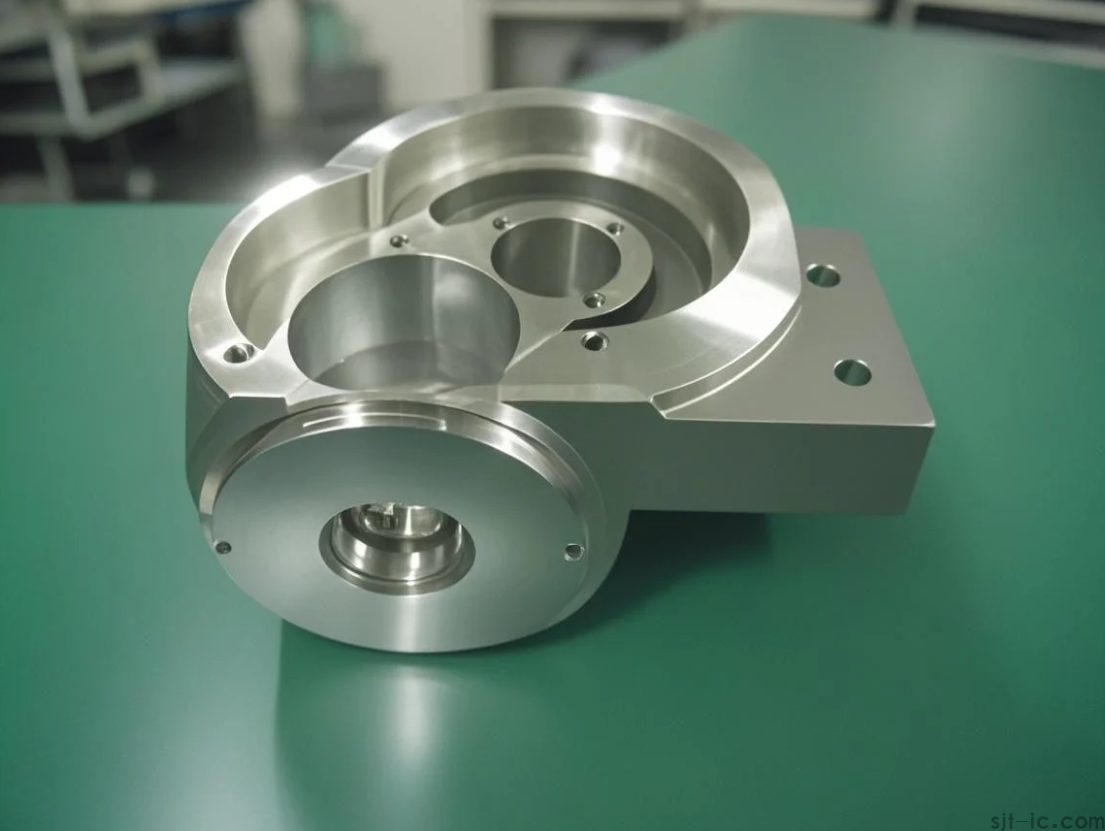

Before we get into the "why," let's quickly cover the "what." In simple terms, CNC machining is a process where computer-controlled machines cut and shape a solid block of material (like aluminum or titanium) into a final part. Think of it as a super-precise, automated sculptor that can create incredibly complex shapes. For electric vehicles, this means everything from motor housings and heat sinks to battery connector plates can be produced with this technology. It's all about removing material to get the perfect form, which offers some unique perks for EV manufacturing.

Benefit 1: Unbeatable Precision and Tight Tolerances

When it comes to EV parts, "close enough" is rarely good enough. A misaligned motor mount or a poorly fitted battery component can lead to big problems. This is where CNC machining truly shines.

• Micron-Level Accuracy: CNC machines can achieve tolerances within a few microns. This means every part is virtually identical to the last, ensuring perfect fit and function every single time. For the demanding world of electric powertrains, this consistency is non-negotiable.

• Complex Geometries Made Simple: Need a complex cooling channel inside a component? CNC machining can handle that with ease, something that's often challenging for other methods. The ability to create intricate designs opens up new possibilities for optimizing EV performance and thermal management.

Benefit 2: Superior Material Strength and Performance

EV parts operate under stress, heat, and constant vibration. Using the right material is crucial, and CNC machining gives you the freedom to choose from a wide range of engineering-grade materials.

• Material Integrity: Unlike processes that melt and reshape material (like 3D printing), CNC machining works with a solid block. This preserves the inherent strength and properties of the material, resulting in more durable and reliable parts. The final component is denser and often has better mechanical properties.

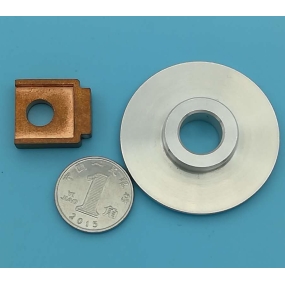

• Broad Material Selection: Whether you need the lightweight strength of aluminum, the thermal conductivity of copper, or the ruggedness of stainless steel, CNC can process them all. This flexibility allows you to perfectly match the material to the part's function within your EV.

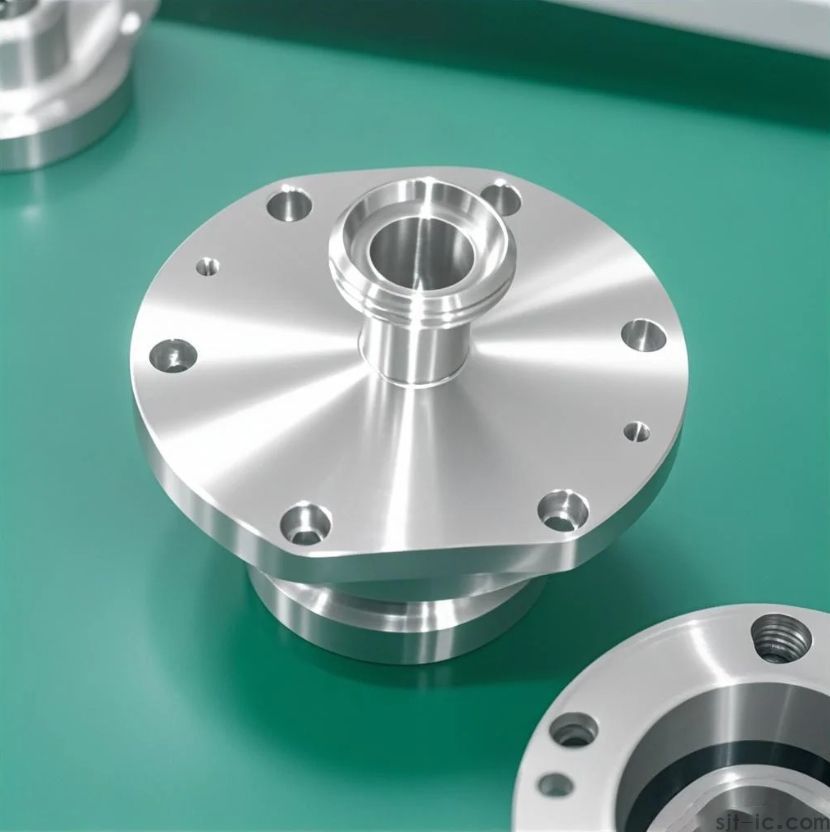

Benefit 3: Stunning Surface Finish Right Off the Machine

First impressions matter, and a high-quality finish often reflects the overall quality of the part. While a perfect surface finish is often seen as a sign of high quality, the relationship between surface texture and a part's long-term functional performance is an area where specifics can vary greatly depending on the application.

• Reduced Post-Processing: CNC-machined parts often come out of the machine with a very smooth surface. This can save you time and money on additional finishing steps like sanding or polishing. You get a part that looks and feels professional, right from the start.

• Consistency Across the Board: Just like with dimensions, the surface finish is consistently reproducible across a production run. This ensures a uniform look and feel for all your components, which is great for brand image and quality assurance.

Benefit 4: The Power of Rapid Prototyping and Scalability

The EV industry moves fast. You need to iterate designs quickly and scale production efficiently. CNC machining supports this workflow beautifully.

• From CAD to Part in No Time: Once you have a digital 3D model, you can have a physical, functional prototype in your hands incredibly fast. This speeds up your testing and development cycle dramatically.

• Seamless Transition to Production: The same process and programming used for prototyping can be used for full-scale production. This eliminates the need to retool or change manufacturing methods, making scaling up a much smoother process. However, it's worth mentioning that for massive production volumes in the hundreds of thousands, the economics might shift towards other methods like casting—the specific cost-benefit analysis for ultra-high volume is a topic we can explore another time.

Benefit 5: Unmatched Reliability and Repeatability

Perhaps the most underrated benefit is reliability. For procurement managers and business owners, a reliable supply chain is everything.

• Zero Defects is the Goal: While no process can guarantee a literal 100% perfection rate, the automated nature of CNC machining gets you extremely close. The high level of automation minimizes human error, leading to a very low defect rate and consistent, high-quality output batch after batch.

• Long-Term Partnership Potential: When you find a CNC machining partner who delivers consistent quality, you've found a valuable asset. This reliability builds trust and allows you to plan your production with greater confidence and less risk.

So, there you have it. From the non-negotiable precision to the flexibility in scaling, CNC machining offers a compelling package for electric vehicle part manufacturing. It's a technology that aligns perfectly with the demands of innovation, quality, and speed that define the EV industry. What has your experience been with sourcing machined parts? I'd be curious to hear what factors weigh most heavily in your decisions. 🤔

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque