Feeling overwhelmed by countless CNC Machining shops online, all promising "high precision" and "great quality"? You're not alone. Many purchasing managers and engineers face the same headache: how to find a truly reliable partner for your critical alloy parts, not just another vendor who might cause delays or quality nightmares. Let's cut through the noise and find a practical path forward.

What Makes a CNC Alloy Machining Supplier "Reliable"?

This is the core question. A reliable supplier isn't just about having fancy machines. It's a combination of three things working together: consistent quality control, transparent communication, and problem-solving capability. Think about it. You can get a perfect sample, but can they keep that standard for batch order 500? They might be cheap, but do they disappear when a technical issue pops up? True reliability shows up when things get tough, not when everything is smooth.

Key Factors You Must Check (Beyond the Price Tag)

Price is important, but it can be a trap. Here’s what to dig into:

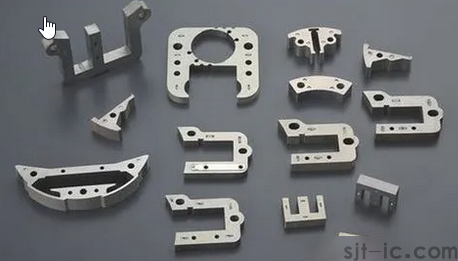

1. Their "Proof" of Expertise with Alloys: Don't just take their word for it. Ask for specific case studies or photos of finished parts made from materials like aluminum 6061-T6, stainless steel 316, or titanium Ti6Al-4V. A shop experienced with alloys will talk confidently about challenges like heat dissipation, tool wear, or holding tight tolerances on "gummy" metals.

2. Communication Flow: Pay attention to how they respond to your initial inquiry. Do they ask clarifying questions about your application, tolerances, and post-processing needs? Or do they just shoot back a price immediately? The first approach perhaps suggests a partner mindset; the latter often indicates a transactional one.

3. Willingness for a Small Test Run: A confident supplier is usually open to a small pilot order. This is your lowest-risk way to test their quoted lead time, quality documentation (like inspection reports), and packaging. It's a practical step many overlook.

The Hidden Red Flags Many Buyers Miss 🚩

Here are some insights from my own experience. Sometimes, a website looks professional, but these subtle signs can hint at trouble:

• Vague Capabilities List: If their website says they machine "all metals" without specifying alloys or showing machine models, be cautious. Real workshops know their limits.

• No Discussion on Design for Manufacturability (DFM): A good partner will offer friendly DFM feedback to save you cost and improve your part, even before you place an order. Silence on this front might mean they'll just machine your design as-is, flaws and all, and charge you for it.

• Overly Promised, Under-Delivered Timeline: If their quoted lead time is unrealistically short for complex alloy machining, it might indicate inexperience or that they are planning to outsource your job without telling you. However, it must be said, some shops are just highly efficient. The key is to ask *how* they achieve such a fast turnaround.

A Practical Step-by-Step Evaluation Plan

Okay, so how do we use this? Let's make a plan:

1. Shortlist 3-5 Shops: Use specific long-tail search terms like 〖precision aluminum CNC machining services〗 or 〖small batch titanium CNC milling〗 to find specialists, not generalists.

2. Send a Detailed RFQ: Include your drawing, material spec, quantity, and key requirements (e.g., "anodizing required," "critical ±.05mm tolerance on bore diameter").

3. Compare Their Responses: Look at the questions they ask back, the clarity of their quote, and their proposed process flow.

4. Request a Video Call or Facility Tour: Seeing the workshop, even virtually, builds huge trust. You can see their machine park, cleanliness, and team.

5. Start with a Pilot Order: Validate everything with a small, non-critical order first. This is your ultimate test.

Ready to Find Your Match?

Choosing the right CNC alloy machining partner is a mix of careful research and trusting the signals. It's less about finding the perfect shop and more about finding a proactive, transparent, and technically sound team you can build a long-term relationship with. The goal is to turn a sourcing headache into a competitive advantage for your projects.

If you have a specific alloy part in mind and want to discuss the feasibility or get a professional DFM opinion, the best next step is to share your requirements with a technical team directly. Why not start a conversation with a potential partner today? Click here to connect with our engineering and quoting team for a personalized review.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque