Feeling overwhelmed trying to pick a stainless steel CNC Machining manufacturer that won't let you down? You're not alone. 🤔 Getting parts that look right but fail in real-world use is a real headache. This guide cuts through the noise, showing you exactly what to look for beyond a shiny website.

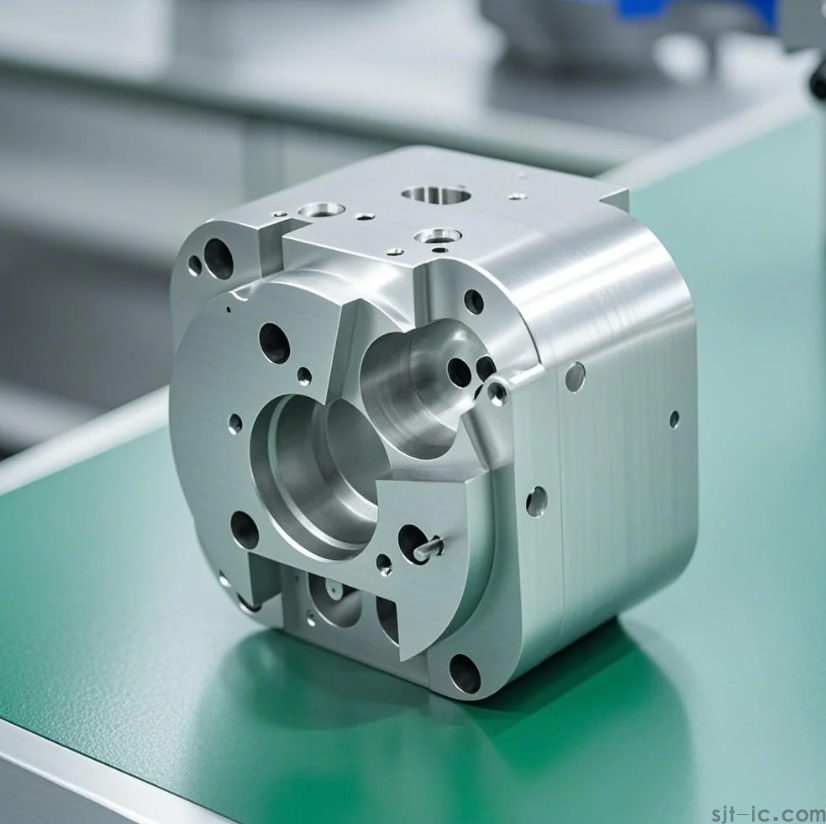

What's the Real Meaning of "Good Quality" in CNC Machining?

It's not just about a part looking nice. True quality means the part fits perfectly, works reliably, and lasts a long time. Think of it this way: a manufacturer with good quality consistently delivers parts that meet your drawings and perform as expected, batch after batch.

Check #1: Don't Just Look at Their Gallery, Ask for REAL Case Studies

Anyone can post nice pictures. A trustworthy manufacturer will share detailed case studies. Look for stories that explain a client's challenge and how they solved it. This shows their thinking process, not just the final product. I always ask for examples similar to my own project's complexity.

- Action Tip: Ask them, "Can you show me a project where tight tolerances or a complex design were critical?" Their answer (or lack of one) tells you everything.

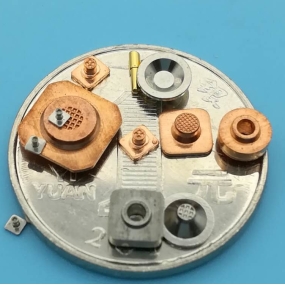

Check #2: The Machines Matter (But Maybe Not How You Think)

Modern CNC machines are a must for precision. However, an older, well-maintained machine operated by a skilled engineer can often produce better work than a new machine with an inexperienced operator. The real question is about their equipment maintenance and operator skill. Don't just ask "How new are your machines?" Ask, "How do you ensure your machines stay accurate?"

Check #3: Their Quality Control Talk Should Be Specific

Hearing "we have strict QC" is a red flag if it's not backed up. You want to hear about specific steps. Do they use calipers, CMMs, or optical scanners? Is there a first-article inspection report they can share? A quality-focused shop will be proud to walk you through their checking process. This is perhaps the biggest hint of their true capabilities.

- Personal Insight: I'm more impressed by a manufacturer that points out a potential difficulty in my design upfront, rather than one that just says "yes" to everything.

Check #4: The Material Source is a Hidden Secret

The best machining can be ruined by poor-quality stainless steel. Ask where they source their raw materials. Reputable suppliers provide material certifications. A good manufacturer won't hesitate to tell you their source or show you the certs. This directly impacts the corrosion resistance and strength of your final parts.

Check #5: Communication: The Make-or-Break Factor

How do they handle your questions? Are they responsive and clear? Pay attention to the questions *they* ask you. A partner who asks detailed questions about the part's function and application is investing in getting it right. On the other hand, slow or vague communication before an order is a warning sign of what's to come later.

Ready to put these checks into practice and get a real conversation started? Our team is ready to discuss your project specifics and provide the detailed answers you deserve. 💬

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque