Are you sourcing precision valve parts and feeling overwhelmed by the technical maze of CNC Machining? You know that even a tiny flaw can lead to major system failure, but finding a partner who truly gets "precision" can be a challenge. Let's break it down together and get you the clarity you need. 🤔

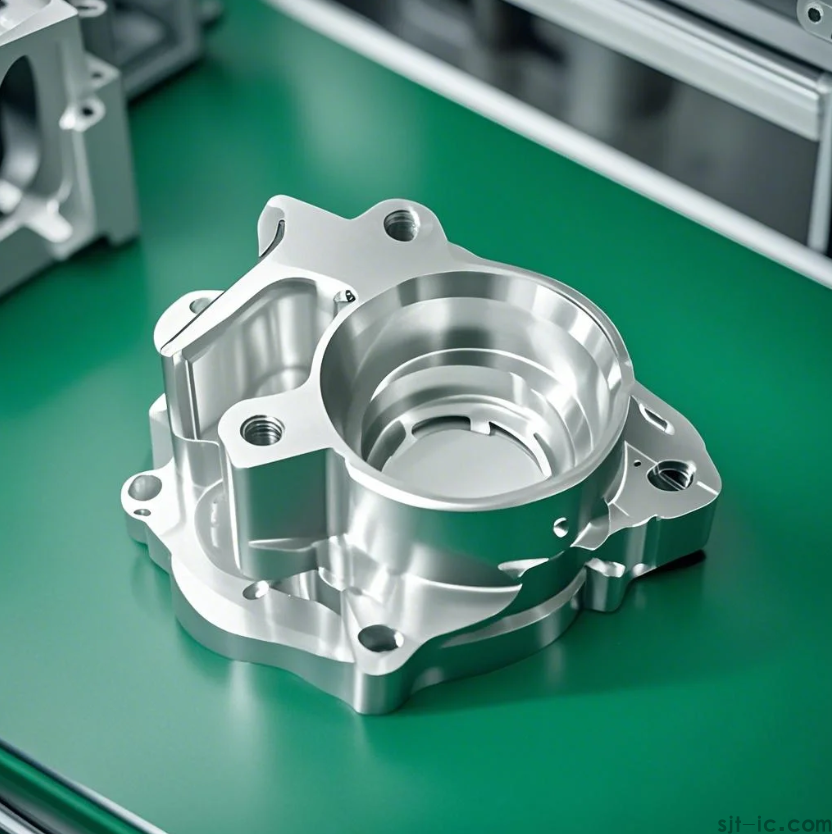

What Makes a Valve Component "Precision" in CNC Machining?

This is the core of it all. A "precision" valve part isn't just about being made well; it's about being made exactly right, every single time. We're talking about dimensions and tolerances so tight that they're measured in microns. Think about the seal in a critical valve – if it's off by even a hair's breadth, it might not seal at all, or it could wear out prematurely. The goal is perfect function and a long, reliable life under pressure.

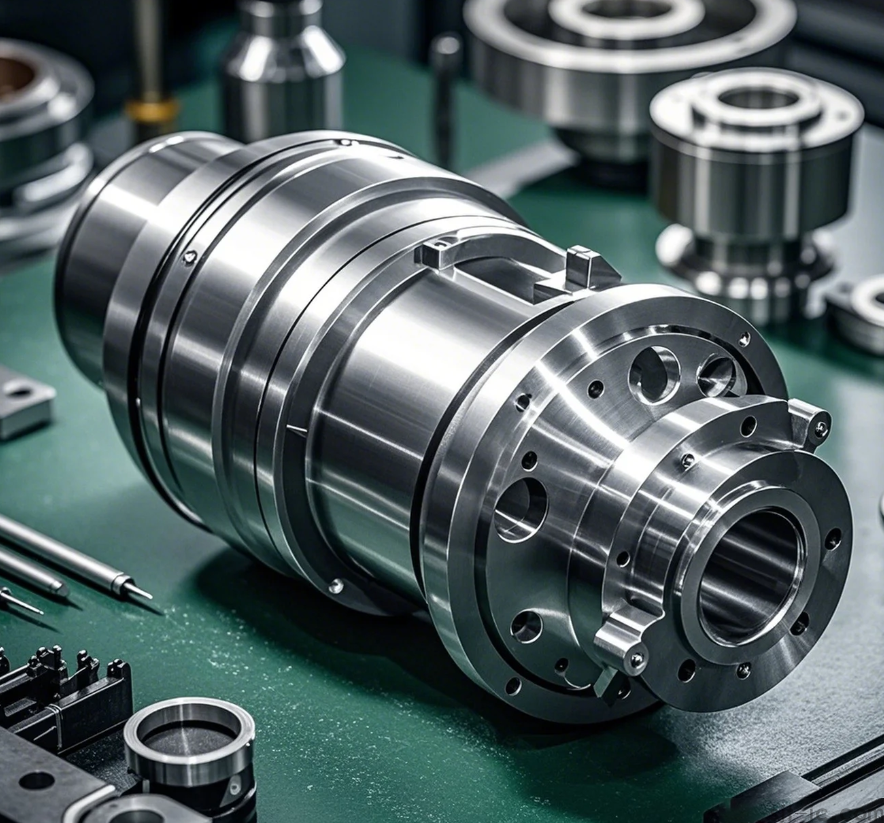

How is This High Level of Accuracy Actually Achieved?

It's a combination of three key things working together:

1. Advanced Machines: Modern CNC machines are incredibly stable and can make incredibly fine movements.

2. The Right Tools: Using specialized, sharp cutting tools is non-negotiable to avoid deforming the material.

3. Skilled Oversight: While the machines do the work, experienced engineers program them and monitor the entire process to catch any tiny deviation.

It’s a symphony of technology and human expertise, not just a button you press. 🛠️

Which Materials Work Best for Durable Valve Parts?

Material choice is a huge part of the performance puzzle. While stainless steel is the common go-to for its strength and corrosion resistance, it's not the only player.

• Stainless Steel (like 304 or 316): Great all-around choice for many fluids and environments.

• Brass: Good for lower pressure applications and has natural anti-corrosion properties.

• Duplex Steel: For the really tough jobs, like handling seawater or aggressive chemicals.

The "best" material always depends on what the valve will face – the fluid, the pressure, the temperature. Matching the material to the mission is what separates a good part from a great one. Sometimes, the more expensive material upfront saves you a fortune in replacements down the line.

Is a Super Smooth Surface Really That Important?

Absolutely, yes. The surface finish might seem like a minor detail, but it's critical. A rough surface inside a valve can create turbulence, trap particles, and become a starting point for corrosion and wear. A mirror-like smooth finish, however, allows for a perfect seal and lets the fluid flow efficiently. It directly impacts the valve's performance and lifespan. Getting the finish right is a sign of a shop that pays attention to the details that truly matter. ✨

Can Any Machine Shop Deliver True Precision?

This is the crucial question. Many shops can claim to do precision work. The difference often lies in the quality control process. A shop serious about precision will measure parts at multiple stages, not just at the end. They use tools like CMMs (Coordinate Measuring Machines) to verify that every single dimension is perfect. They document everything. This rigorous checking is what gives you, the buyer, confidence. It's the hidden cost and the true value.

However, it's worth mentioning that this level of care does come at a cost. You can't get true, certified precision at bargain-basement prices. The investment, though, is in reliability and peace of mind.

Choosing a partner for your precision valve components is more than just picking a supplier; it's about finding someone who understands the stakes. It's about the relentless pursuit of perfection in every cut. If you're looking for that level of commitment and have a project that demands nothing less, why not start a conversation? Our team is ready to discuss your specific requirements and provide a solution you can count on. 💬

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque